Xizi Gears Up for the Future

Apr 1, 2014

The global elevator component supplier releases new products amid business partners and honored guests.

Xizi Elevator Group Co. Ltd. invited some 80 celebrity business partners and honored guests for a product release on October 16, 2013. Hosted by Chen Gang, executive president at Xizi Elevator Group Co. Ltd., the release was held at the Dragon Hotel in Hangzhou and showcased a series of the latest developed products by the group’s member companies. The products featured, among other attributes, improved reliability and efficiency, combined with greater safety and energy-saving performances.

In order to meet the demanding and particular requirements from both domestic and global markets, Xizi Group sets great store by innovation, studying new technologies and their applications. The group listens to its customers’ changing needs and makes those needs a priority, incorporating detailed requests in the products. In today’s highly competitive, globalized market, Xizi Group finds customers appreciate the efforts made to realize the optional features of its products.

After an unveiling ceremony of the new products, several Xizi Group members addressed attendees, discussing the newly introduced products, as well as the company’s future, while China Elevator Association (CEA) Secretary Zhang Lexiang spoke about the future of the Chinese and global elevator markets.

Zhang Lexiang, Secretary General of CEA China

“The first nine months of 2013 saw a steady increase in elevator production, especially an increase in profit by manufacturers in the elevator industry. With more than 1 billion m2 in area having been completed by the construction industry in China, the country’s elevator market will continue to promise good prospects for years to come. However, the new national standards to come into effect in the beginning of 2014 will pose challenges to the manufacturers, for example, the perfect documentation regarding safety and technical regulations to go with products and the product call-back system. So, members of our industry should get adapted to and prepared for the new codes and standards for continued development in the future.”

Chen Gang, Executive President of Xizi Elevator Group

“Encountering the changes and challenges in the elevator industry, Xizi UHC attaches great importance to the requirements by the new standards, which calls for our good preparations. Today’s product release will demonstrate to everyone present what we have done in response to the changes in the future standards and the needs of our business partners. We hope to take the opportunity for exchanges with participants as a promotion to the development of our industry. . . . Xizi Optimax Technologies has provided tailored designs and products for our major business partners like Otis and KONE; however, I’m confident that the same tailored service will open to other customers.”

Chen Xiaxin, President of Xizi UHC

“Thank you for your long-term trust and support to the development of Xizi UHC and taking time in participation of today’s Xizi product release. The increasing number of elevators in operation and their varied working conditions call for higher reliability of elevator parts and components. This is best understood by a call-back technician who is hurrying to a jobsite for troubleshooting, while another breakdown is reported. A patient may think the medicine prescribed to him is too expensive, and a sick lift may mean the same thing, taking thousands of yuan from the owner’s pocket at a time to pay for the materials, hours and travel expenses of the repair technicians.

“Out of our 30 years of experience, Xizi gives top priority to product reliability. Out of the money we have earned in the past, Xizi Group has invested heavily in R&D, with a view to raising product reliability.We regard it as our social responsibility to always reward our customers and business partners with increased product reliability by making Xizi elevator components the synonym for having seldom breakdowns or no breakdown.”

Yang Zhihua, General Manager of Xizi Forward Machinery

“I would like to extend thanks to all business partners on behalf of Xizi UHC. Thank you for your continued support and trust in Xizi products over so many years. We have delivered 380,000 traction machines to both domestic and global markets since 2002 and kept field tracking records of the machines in operation. The records show that all the machines at work have remained in good shape and condition, including the very first shipment in August 2002. The support and needs from the customers is the drive of our R&D for continued improvements in every detail of the products. For example, the GETM3.0R adopts an intelligent temperature control, which starts and stops the cooling fans at precisely timed moments. The working life of the fans lasts as long as 50,000 hrs, and a service button allows easy inspection and replacement. We have also successfully developed traction machines for high speeds up to 7 mps and shipped them lot by lot, with 14 machines in the biggest shipment. The GETM12C is developed jointly with Japanese experts. Seven optimized features make it a safer and perfect choice for installations in high-rise buildings.”

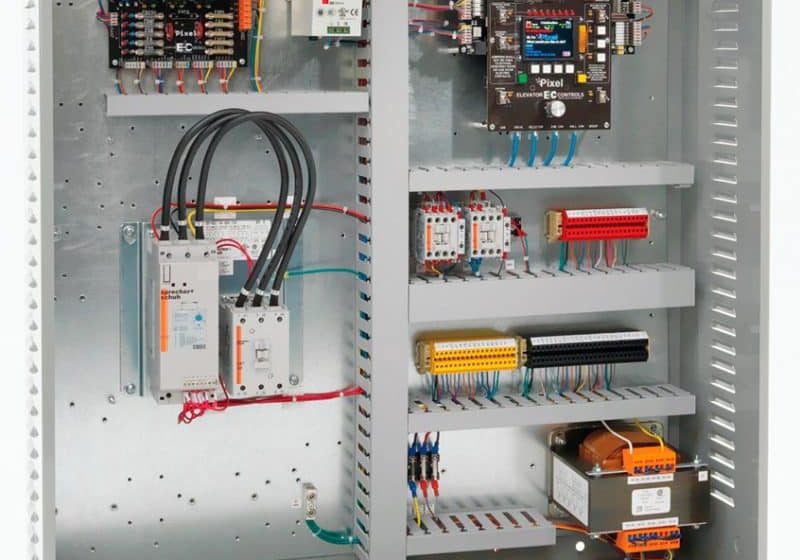

Chen Liang, Xizi Optimax Technologies

“Xizi Optimax Technologies is specialized in elevator controls and man-to-machine interface components for elevators. The man-to-machine interface components include push- or touch-button panels with information feedback screens and LCD indicators. In 2013 alone, the company provided 300,000 sets of panels of varied types and a million indicators for the market. As these components feature the most frequent usage by passengers, we have been devoted to developing products with durability, reliability and good aesthetics in order to bring wonderful experiences to users, in addition to creating the value of the brand.

“High-definition LCD screens, including the ultra-thin LCD, are widely used in our products, which have to undergo stringent electronic and mechanical tests, such as tests of static electricity, noise and humidity etc., respectively, for a low fault rate under 0.2%. Based on experience and expertise, we have been tailoring our designs to particular needs of customers, too.”

Qian Dongqing, General Manager of Xizi Trust Tech

“Xizi Trust Tech, equipped with the door-drive-making facilities, was a late comer to start with door-drive systems in 2006, but we have made amazing progress ever since. In 2009, we released our first generation of new products, followed by twin-motor door drives in 2011. We are the first door-drive manufacturer to provide permanent-magnet door systems in China, having shipped more than 100,000 PM door drives to date. We’re proud to say that Xizi Trust Tech has topped the suppliers, making the biggest shipment by units (42,000 in 2012; 63,000 in 2013) in China. As door systems play a key role in the efficiency of a lift installation, we have managed to bring down the closing time to 1.9 s and the opening time down to 1.3 s, while bringing the capacity up to 400 kg from 120 kg. The average noise stays lower than 50 dB, with the maximum not exceeding 55 dB, meanwhile upgrading the protection class up to IP54.

“Our door drives must undergo jobsite imitation tests, including sliding the door panels in the guide groove filled with sand. We listen carefully to complaints from customers so as to find out problems in order to enhance product reliability from time to time. The breakdown rates are going down: from 0.75% in 2012 to 0.59% in 2013, including new installations under testing, but I’m confident the breakdown rates of Xizi door drives in normal operation will stay well below 0.5%. As safety is the most important issue with door systems, we spare no efforts to improve safety performances of our products, and a series of new technologies will find applications in our future products, including using the synchronous car-door cams.”

Get more of Elevator World. Sign up for our free e-newsletter.