Yacht Obsession

Jan 1, 2020

Innovative engineering leads to wheelchair-access solution for lobster yacht.

submitted by John C. Linsley, Gillespie Corp.

Now using a wheelchair, John Bowen has been boating since he was a young boy. His boat, a Northern Bay 38 named Obsession, is referred to as a “lobster yacht,” a working boat that has been modifed to serve as a pleasure boat.[1] It has been completely redone, including making it wheelchair accessible thanks to three devices, the last of which is the subject of this article.

Access means from dock to boat were solved and built locally. After seeking solutions for a way to access the cabin from the deck for more than a year, Bowen contacted Gillespie Corp. The problem was getting from the main deck down a 30-in. vertical rise to the cabin foor. The lift could not interfere with the stairs, and, when in the parked position, the lift had to ft fush with the lower landing.

The available power source was either 24 or 12 VDC. The lift was required to move 550 lb — the combined weight of the wheelchair and Bowen. Concerns were raised regarding a loss of power resulting in entrapment in the cabin below, so a further requirement of emergency manual operation was stipulated. This operation had to take place at the main deck, as the possibility of the lift stopping halfway down could not be discounted. With the lift stuck partway, it would not be possible for anyone to get from the deck down to the cabin. In addition, the wheelchair — when not at the lower landing — needed to be prevented from falling of the end of the platform.

An onsite survey of existing conditions was the frst step. Bowen, the fberglass installer, the woodworker and Gillespie met at the boat and discussed options. Gillespie discussed what the owner wanted from the lift: use, capacity, speed and required features. Gillespie submitted drawings refecting feld conditions. After a few revisions, it was agreed the drawings were accurate. Gillespie’s frst thought was to design an inclined platform lift with two small winding drums and small-diameter wire rope. The lift would be guided on either side by some form of rail-and-shoe arrangement.

Next, Gillespie called Deborah Mellen, founder of the Impossible Dream. Mellen is a successful businesswoman who is a paraplegic. Impossible Dream is a universally accessible 58-ft catamaran that provides individuals who otherwise may not be able to sail the ocean the opportunity to do so. Gillespie had designed and built a custom wheelchair lift for Mellen’s home, so we contacted her and asked that she have the Impossible Dream’s captain send us pictures of its handicapped-accessible lifts. We were pleasantly surprised to fnd one of the lifts very similar to what we had in mind. This confrmed we were headed in the right direction.

Gillespie signed a consulting design agreement with Bowen. This ushered in an intense period of information gathering on available components to be incorporated into the design and refected in the drawings. The design uses a gearmotor to turn a driveshaft with two wire-rope drums. Between the driveshaft and gearmotor is a coupler that allows the driveshaft to disengage from the machine. At the opposite end of the driveshaft is a sprocket and roller chain driven at deck level by a hand winch. After considerable revisions, we submitted the drawings to Bowen. After his approval, the lift went into production.

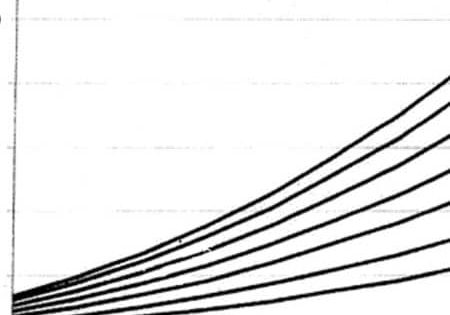

The least-difcult aspect of the design was the machine and twin drums. Early on, Gillespie realized we needed to both lift the platform from above with wire ropes and have lower ropes follow the platform from below to keep it from bouncing when Obsession was on the open ocean. To do this, we decided to have single-groove drums in both the left and right threads with two ropes on each drum. As the upper rope is fed onto the drum, the lower rope feeds of it, and vice versa. We had never seen this done before, but it works quite well.

The right and left drums are mounted to the driveshaft on either side of the lift. The machine is a small SEW-EURODRIVE gearmotor with a 1/2-hp, 24-VDC motor. It is coupled to the driveshaft with a splined shaft coupler. This coupler can be operated from the deck above by a cable to allow the gearmotor to disengage from the driveshaft. The idea for this arrangement was from a similar coupler that precludes transmission wear by allowing a car being towed by an RV to disengage the wheels from the transmission.

Wire ropes that attach to the car from above and below pass over defecting sheaves against the stairwell on either side. The lift is guided by linear guides and shoes, and travels at an approximately 50˚ angle. This allows it to just miss the leading edges of the stairs.

The manual winch was required to have a handle-actuated brake mechanism. The handle itself causes the braking action. This winch was heavily modifed to turn the upper sprocket, which, through the roller chain, operates the lower sprocket and driveshaft.

One of the most difcult aspects of the design was the means preventing the wheelchair from rolling of the front end of the platform when the lift is above the lower landing. We knew we wanted this to be mechanically operated and fush with the deck below. We settled on a simple, spring-loaded bar on either side of the platform that rotates above the centerline of the front wheels of the wheelchair, stopping it from moving forward once in contact with the bars. During normal operation, the wheelchair is far enough back that the bars are free to move into the retracted position as the car comes into position at the lower landing. The roller mechanism was designed to slip relative to the bars. So, in the event of the wheels preventing rotation, the mechanism itself will not be bent or damaged.

One of the more interesting problems we encountered during testing was that the lift, when loaded, would not completely stop in the down direction. Going up, the brake would activate, and it would stop and hold position as intended. In the down direction, upon releasing the “down” button before stopping on the lower limit switch, the car would continue to slowly travel until it reached the pit bumpers. After much handwringing, we found that we had wired both the motor and brake leads to the power terminals, and the gearmotor was backhauling enough that the brake remained picked by the generated current from the DC motor. It was a simple matter to relocate the brake leads to a separate power source on the contactor.

The entire lift was manufactured from 304 and 316 stainless steel, with the exception of the gearmotor, splined shaft coupler, sprockets, roller chain and winch.

Sequence of Normal Operation

The lift serves two levels, with call and send buttons on a pendant with an extension cord. The platform would normally be parked at the lower landing, fush with the cabin foor. To use the lift, one presses the “up” button on the pendant to call it to the upper landing. As the lift rises, the restraining bars automatically deploy. The platform will stop on the upper normal limit switch. Access to the platform is achieved with feet facing the bow; the lift stops when the wheelchair encounters small bumps mounted to the platform. These bumps position the wheelchair for proper use.

Using the “down” button on the pendant lowers the platform to the lower landing, fush to the foor. The platform automatically stops on the lower normal limit switch.

Restraining devices automatically rotate to the retracted position to allow the wheelchair to exit the lift. Because the control system is under constant pressure, the button must be held in position until the lift stops. A short delay is built into the up-and-down button circuits to prevent chattering the motor.

Manual Lift Operation

In the event of power failure or gearmotor breakdown, it is possible to manually raise the lift to the upper landing. One frst locates the removable winch handle and screws it onto the winch’s threaded shaft. Then, one gives it a good push so the winch brake (activated by the handle) takes the load.

Flipping the manual coupler release disconnects the gearmotor from the driveshaft. If this is difcult, one can return to the winch to either lift or lower a small amount of weight to take load of the splined coupler shafts. The winch may be used to raise or lower the platform once the decoupler has disconnected the lift from the gearmotor. The winch handle force is 8-10 lb.

To reconnect gearmotor and driveshaft, the coupler release should be returned to the original position to rejoin the splined shafts. It will most likely be necessary to gently shake the winch handle until the splined coupler slides back onto the splined shafts. This action is spring loaded. One knows when the coupler is in place, because operating the winch handle in the down direction only unscrews the handle from the winch. This is due to the gearmotor brake now holding the load. Once power is restored, one may operate the lift as described above.

Conclusion

This lift design was quite challenging, yet very rewarding. The engineers and fabricators at Gillespie worked together to produce a unique wheelchair lift that provides the last part of accessibility that makes this lobster yacht a pleasure for its owner to use. I am happy to have been part of the project and grateful to everyone who contributed.

Reference

[1] Tammy Kennon. “Lobster Yachts: Working Boats Recast as Pleasure Craft,” USA Today, June 7, 2016.

Get more of Elevator World. Sign up for our free e-newsletter.