Connecting with Customers

Sep 1, 2025

Adams to present safety technology and live product demos at NAEC 2025 as it reflects on its history of innovation.

submitted by Adams

As it approaches its Centennial, Adams Elevator Equipment Co. continues to respond to customers’ needs as elevator safety codes and standards change. The company has been a participant in the National Association of Elevator Contractors (NAEC) annual convention for many years, and this year will be no exception as it plans to present several of its key products to enhance elevator safety and modernization. Although it is headquartered in Chicago, today Adams team members mostly work remotely, although they collaborate and come together frequently for industry events throughout North America.

The Early Days and Beyond

What began as a small storefront in Chicago in 1930 has evolved into an industry powerhouse with more than 30,000 parts in stock — 97% of them shipping the same day. Adams Elevator’s steady focus on code compliance and field-tested reliability has made it a go-to resource for elevator mechanics and operators across North America and beyond.

James Adams and Joseph Coulombe founded Adams Manufacturing in the early 1930s after recognizing the industry’s urgent need for reliable elevator equipment. Their first job was Chicago’s Union Station, a massive transportation hub. In the 1940s and 50s following World War II, urbanization surged and demand for modern elevator systems skyrocketed. The elevator industry saw significant innovations in speed, efficiency and safety, and Adams capitalized on this growth, supplying elevator parts for systems throughout the U.S.

Fast forward to 1981, when Adams became a leader in elevator safety with the introduction of its patented Survivor® push buttons, designed to withstand high impact and provide lasting durability in high-traffic elevator systems. The 1990s were an era of expansion for both the industry and Adams Elevator. In 1994, Adams moved into a 150,000-ft2 facility in Niles, Illinois, increasing production and streamlining operations. As demand for advanced parts grew, Adams also expanded its variety of components.

The 2010s until now represent a period of modern developments. In response to demand for smarter, more connected safety systems, Adams introduced the HatchLatch® door restrictor and Safe-T-Lock intelligent door monitor. Adams placed more emphasis on customizable solutions to meet diverse customer needs, which continues today.

Adams at NAEC

The company is featuring several new products and innovations at the NAEC 2025 Convention and Exposition in Houston, Texas, on September 15-18, including hands-on demonstrations of three standout products. These are:

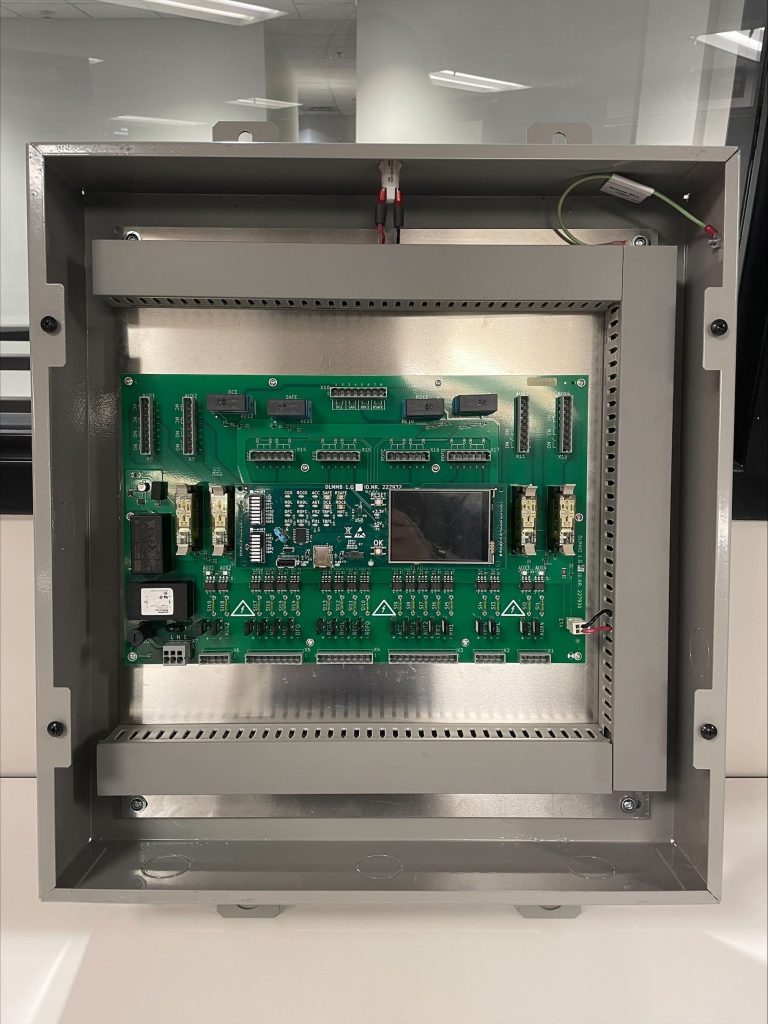

- DLM 2: Many monitoring systems are bulky, hard to fit and require extra parts or relays, making compliance with evolving safety codes a hassle. Set to launch in 2026, Door Lock Monitoring (DLM) 2 is Adams’ answer to these everyday frustrations. Recognizing the challenges professionals face in installation and maintenance, Adams engineered DLM 2 to be as user-friendly as it is powerful. One of its standout features is its smaller form, which allows for flexible placement even in tight or awkward spaces, making it easier to fit into a variety of elevator designs. One mechanic can install both the front and rear units, streamlining the process and reducing labor costs. Additionally, there’s no need to install extra relays in the elevator controller since both the auxiliary and DLM bypass relays are built directly into the printed circuit board assembly. DLM 2 also supports a wide voltage range, from 300 VAC/DC to 24 VAC/DC inputs, making it adaptable to diverse elevator systems. Adams believes that DLM 2 sets a new standard for code compliance and operational efficiency by simplifying installation and enhancing diagnostic capabilities.

- HatchLatch: Since its introduction in 1995, HatchLatch has played a pivotal role in elevator safety, addressing critical safety risks that once put both passengers and technicians in harm’s way. Before HatchLatch, passengers attempted risky self-rescues and technicians frequently faced risks due to inadequate hatch security and a lack of clear door and hoistway position feedback. As codes changed, many solutions lagged, leaving gaps in safety. Adams rose to meet those challenges head-on with the original HatchLatch A1, revolutionizing car door security standards. The system ensures doors lock securely whenever an elevator isn’t aligned with a landing, preventing occupants from leaving the car until help arrives. Over the years, Adams has continuously improved HatchLatch through multiple iterations — A1 in 1995, A2 and A3 in the early 2000s and the streamlined A4 version introduced in 2014 — each enhancing reliability and safety. Today’s HatchLatch doesn’t just meet challenging safety codes, it exceeds them, providing peace of mind to building owners, technicians and, most importantly, passengers who rely on safe, dependable elevator service every day.

- CabSafe: At Adams, safety begins the instant the elevator doors open. This philosophy drives CabSafeTM, an innovative solution engineered to protect passengers from their very first step into an elevator cab. In today’s demanding environment, building owners and elevator professionals need absolute confidence that every ride delivers maximum safety, regardless of building configuration, door style or traffic patterns. The CabSafe 2D Light Curtain combines a 2D light curtain and 3D Time-of-Flight sensor technologies for continuous code-compliant detection. Designed to work with all opening styles and dynamic setups, CabSafe ensures simple, reliable operation for worry-free passenger protection. Whether someone is rushing to catch the elevator or a child lingers near the doors, CabSafe is always on guard, ensuring the doors remain open until it’s truly safe to close.

Get more of Elevator World. Sign up for our free e-newsletter.