16 York Street

Nov 1, 2021

TKE tackles a building project in the heart of downtown Toronto.

Due to a strong relationship with the client and the ability to meet schedule demands, TK Elevator (TKE) was chosen to provide the vertical transportation (VT) for a new construction project in Toronto. The commercial office building was constructed in the heart of downtown, making logistics and material delivery a challenge.

16 York Street is a CAD 479 million (US $380.51 million), 32-story premium office building located at the corner of Bremner and York streets in downtown that was constructed from 2017 to 2019. Located in the South Financial Core, Toronto’s most vibrant business community, 16 York is 508 ft tall and encompasses 870,000 ft2.

With its signature stepped exterior and soaring glass wraparound lobby, 16 York’s innovative raised flooring system provides tenants with flexibility and comfort, lower day-to-day operating costs, enhanced environmental control and easy access to heating, ventilation, and air conditioning (HVAC), telecom and data cabling.

There are four levels below grade used primarily for parking. A caisson wall was required along three sides of the project; the south boundary is the below-grade structure of the ICE Condominium development to which 16 York Street is connected.

The above-grade structure is composed of a beam-and-girder concrete piece. The floor slabs are offset 3 m in the east direction and 1 m in the north direction. The typical tower cladding is a unitized curtainwall system, and the ground floor is enclosed with a structural glass fin wall. The west, east and north elevations have a large canopy with a green roof covering the sidewalk.

The typical floors are 25,000 ft2 with raised access flooring and T-bar ceilings. Typical floor finishes are limited to the washrooms and elevator lobbies. The main lobby is fully finished with Italian stone, wood and drywall ceilings. The project was built to achieve LEED Platinum (and has advanced technology for maximum operational efficiency, performance and conservation) and WELL Silver certification (International certification to ensure a workplace environment that promotes personal health and wellness for its residents).

VT Details

TKE supplied 20 elevators for the project. This includes 17 high-speed elevators: six are overhead gearless, low-rise passenger elevators (ground to floor 16); six are overhead gearless, mid-rise passenger elevators (floors 16 to 25), one of which is also a swing service elevator; and five are overhead gearless, high-rise passenger elevators (floors 25 to 33). TKE also supplied one side-mount gearless service elevator and the two, shuttle machine-room-less elevators for the four below-grade parking levels.

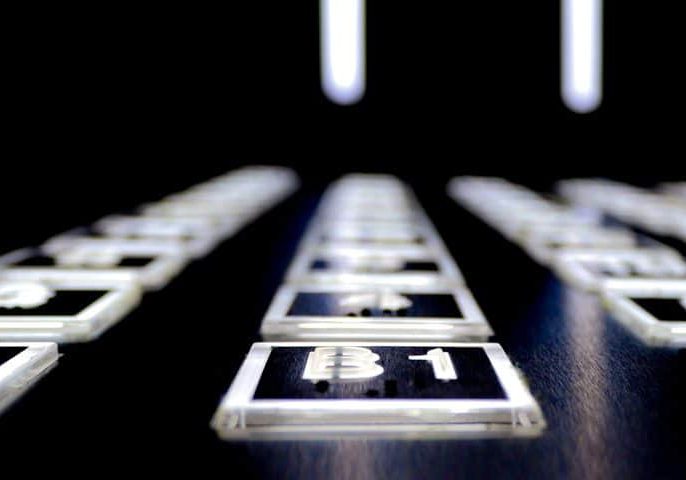

To ensure efficiency in passenger traffic for this commercial building, TKE installed its Destination Dispatch system. This includes LCD touchscreens for call placement with custom-designed faceplates for touchscreens and the lobbies for all of the passenger elevators. Users can select the desired destination floor by touching the appropriate symbol on the touch screen of the call station. The touch screen displays the number of the elevator to which the call has been assigned. The screens can be altered from the Destination Dispatch monitor. Moreover, the screens are integrated with card-reader security and the Cadillac Fairview network system.

About the project, Navid Majidinejad, project manager for TKE, said:

“The project was challenging from a logistics standpoint from the get-go, as it is located right in the heart of downtown, close to the arena where the Toronto Raptors play and events are held constantly. Bringing material to site was something we had to coordinate closely with the city and general contractor.”

Other Details for the Project:

- Flag lanterns are provided at ground floor for all passenger elevators

- High-speed guide rails were provided for the passenger elevators

- For the hoist machine and motor, drive sheave and ropes, governor, dead-end hitch and high-voltage components and tripping hazards in all machine rooms, TKE installed guarding as per specifications.

- The monitoring system was integrated into the Cadillac Fairview security system via a network switch.

Technical Details of the Traveling Cable

- 14 AWG (1.5 mm2) conductors for constant current-carrying circuits

- 18 AWG (0.75 mm2) conductors for signal circuits

- 20 AWG (0.5 mm2) shielded pair conductors with shielding for telecommunications circuits and date

- Coaxial cable for closed-circuit television

- Separate fiber optic traveling cable (cable code CSF5 3-14+2 Single Mode Fiber)

Maintenance of elevators is in accordance with the Cadillac Fairview agreement and Cadillac Fairview elevators and escalators maintenance specification (one year). The elevator design was pre-registered with the AHJ under the CAN/CSA B44-10 Safety Code for Elevators.

Ownership

- The Cadillac Fairview Corporation Ltd.

- Ontario Pension Board

Project Team

- Architect: B+H Architects

- General contractor: PCL Constructions Canada Inc.

- Consultant: KJA Consultants Inc.

- Contractor: TKE

- Elevator manufacturer and component supplier: TKE

- Structural engineer: Entuitive Corporation

- Mechanical engineer: The Mitchell Partnership Inc.

- Electrical engineer: Mulvey & Banani International Inc.

Get more of Elevator World. Sign up for our free e-newsletter.