38th Heilbronn Elevator Days

Jun 1, 2021

The 38th Heilbronn Elevator Days (Heilbronner Aufzugstage) (HAT) held on March 2 and 3 under the heading, “Challenges Facing the Elevator Industry,” brought about 130 virtual participants together (roughly half of those in “normal” years). In just under two days, 12 presentations offered a packed program on elevators and escalators — in addition to individual topics — in five key areas:

- Standardization

- Building information modeling (BIM)

- Dealing with Risks

- Legal Issues

- Cybersecurity

The topics were equally relevant to the elevator industry, planners, operators and users. Georg Clauss, CEO of the Heilbronn Technical Academy (organizer of the HAT), welcomed those gathered at their screens. Klaus Dietel from TÜV NORD, chairman of the conference, then gave a brief technical introduction to the topics. He regretted that the opportunity of in-person networking was missed this year. There were, however, exhibitors to visit online, and participants could meet for live chats.

European and International Standardization

The comprehensive opening presentation by Gerhard Schiffner of TKE on “European Directives, New European Standards” was an integral part of the HAT. The Machinery Directive is due for revision; it will be another year or two before the draft is published. The link with the Lift Directive will be established via safety issues, but the speed limit of 0.15 m/s will remain. As for Brexit, Schiffner pointed out the different regulations for Great Britain (GB) and Northern Ireland. The Notified Bodies (NBs) will lose their status. As of January 1, 2022, safety components and elevators put on the market in GB must comply with the GB Lift Directive. Technical contents and standards and their legal status will remain unchanged. Details have been compiled by the British Lift and Escalator Industry Association and may be accessed at leia.co.uk/ukca-marking-from-1-january-2021.

“European standards for elevators have regained momentum after many years of stagnation,” Schiffner said. The revisions and preparations each have serious technical implications in some cases. Many parts were reissued in 2020; some publications were denied by the European Commission due to legal concerns. Schiffner also offered an overview of ISO standards. Their importance is increasing, for example, due to the replacement of EN 81-20/-50 by ISO 8100-1/-2.

BIM

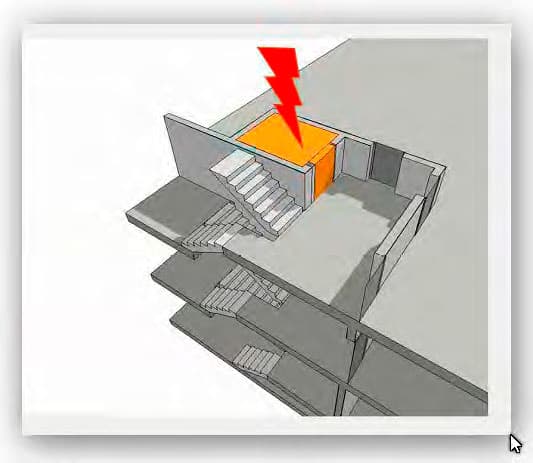

Andreas Pilot of A. Fritsch Architects presented the standard VDI/bS 2552 Part 11.5, “BIM; Exchange Requirements; Elevator Technology,” whose green print (draft) is expected in second quarter 2021 with a six-week objection period. It specifies which data (geometry and contents) are needed for preliminary, tender and implementation planning. The aim is to establish the Association of German Engineers/Verein Deutscher Ingenieure (VDI) standard as part of the contract to create an arrangement-free digital twin. In such a standardized process with fixated input parameters, several elevator manufacturers will be able to incorporate their models.

As a helpful example, Pilot noted that elevator shafts today often do not fit on the construction site and are cut to fit with associated consequences that can be avoided through BIM. It is important to show only space requirements in the early stages, which means showing neither car nor counterweight. The VDI standard, for example, takes care of the same location over all floors — including the elevator. A mistake quickly becomes evident by means of BIM, for example, if a collision results when the opening for the door is not large enough.

Risk Assessments

Andreas Dorsch from Schindler presented the first contents of “EN ISO 14798,” which is currently being revised without a timetable. It facilitates risk assessments for manufacturers and assemblers. A risk assessment is the basis for bringing products into circulation in the EU internal market in conformity with the law, irrespective of the adoption of harmonized standards.

Jörg Jahn from the German Employers’ Liability Insurance Association for Wood and Metal provided a practical reference by explaining “Risk Assessments for Employers and Operators.” Twenty-five years ago, the Occupational Health and Safety Act introduced risk assessment as a central tool for employers. In the special case of elevator systems, according to the Ordinance on Industrial Safety, the employer can be the installer or operator or landlord.

Using the example of a grinding workplace, Jahn demonstrated how to carry out a risk assessment, starting with an evaluation of the working conditions and finishing with improvement measures. All the information is stored in a table that is updated after a change in standards or when an accident has occurred. One can find a sample risk assessment and, if necessary, help in preparing it, at bghm.de. The state rules TRBS 3121 and TRBS 1201 Part 4, VDI 3810 Part 6 and other documents also provide assistance.

Legal Questions and Answers

Volker Sepanski from TÜV Rheinland Industrie Service dealt with “Elevators in Building Law – Accessibility, Fire Protection.” Accessibility is determined in DIN EN 81-70, he said. The standard describes the nature of the disability, the technical requirements and appropriate elevator types. However, a general requirement in the contract to apply the DIN is not satisfactory. It makes sense to select in advance what exactly the elevator will be used for. For example: wheelchair, yes, but learning handicaps, no. In this case, a stair elevator or an adapted passenger elevator or platform lift can be used. DIN EN 18040-1 regulates barrier-free construction in public-access buildings. MBO § 50 (Model Building Code) usually only deals with wheelchair users.

Fire protection requirements for the surrounding area or for cars, among other things, can be found in DIN EN 81-72/73 Firefighters’ Lifts, but also in the Model Building Code, codes of practice on firefighters’ elevators and their testing per city/state, as well as in other papers. Fire protection is not part of the examination of the Notified Body. This test ends at the landing door without including, for example, the wall opening in the machine room or a car floor made of a wooden panel. Only a complex operating principle test with many trades over three to six days provides proof of the availability of the firefighters’ elevators in the event of a fire.

Attorney Hartmut Hardt dealt with current “Legal Issues in the Elevator Industry – Liability for Reconstruction/Modernization.” DIN 32736 Building Management — Terms and Services specifies, among other things, modernization, refurbishment and reconstruction guidelines. DIN standards are not laws, however, so the applicability of these terms may have to be specified in the contract. The recipient expects all work to comply with the state of the art, i.e., the generally accepted technical rules. The recipient’s expectation may significantly exceed this understanding of the contents, scope and/or quality of the corresponding work. If these expectations and fulfillments diverge, there may be a fault that could end up in court.

Cybersecurity

Nico Julian-Hall of Otis presented “The New ISO 8102-20 on Cybersecurity,” a draft version that has been in progress since May 2019. Balloting began in March/April 2021, with publication around September 2022. The standard defines product-related cybersecurity requirements and the minimum cybersecurity level for functions such as safeties or alarms. It addresses product suppliers, system integrators and connected systems. Existing systems are not in the focus. In addition, the standard specifies what must be implemented and in which order:

- Defining the process to ensure security through development and design

- Subsequent testing

- In the case of incidents, focusing on information and communication

- Continuously improving through, for example, hardware and software updates

Conference Chair and Moderator Dietel quoted VDI Nachrichten by stating:

“More than 90% of successful attacks start with a phishing email. Humans are the weakest link. The worldwide damage potential is higher than that of narcotics trafficking. It is a convenient crime based on high expertise.”

Sebastian Eich of hanseConcept spoke on “Cyber Attack and Defense.” The question is not if, but when, you will be struck: 62.4% of organizations have already been hit; 57.5% have paid. The quality of attacks is increasing and done via phishing emails, remote support or malware. So-called ransomware poses the greatest threat. The software explores the system for an average of 50 days. Then, it destroys critical IT structures such as apps or backups by automatically encrypting the systems, usually at night or on weekends/holidays, resulting in loss of reputation, ransom payments or even the selling or publishing of company secrets or sensitive data.

Eich described in detail a situation faced by his customer, an elevator manufacturer, where everything started with the following message on the screen: “Your network was hacked. Your ID: … Do not reset or shutdown your PC or server. Info http://…” The resulting massive operational disruption affected all sites for approximately 80 days until regular operations were restored in four stages.

Key Individual Topics

Frank Saalmüller from Schaefer dealt with “Hygienic and Smart Elevator Operation.” The company has set up its own hygiene division for this purpose. This investigates and optimizes the influence of, among other things, design, materials and components in elevator cabs and on operating panels inside and outside the cab. Three main potential infection paths have been identified: car air, contact surfaces and direct, human-to-human contact. Typical areas of use and building types were categorized as: hospitals, medical centers, care facilities, public facilities, government agencies, mass transit, schools and shopping centers.

Various hygiene categories (sterile, hygienic, pure, clean) were defined; products and solutions were assigned to them. Common and useful solutions were named as: disinfection in and in front of the elevator; materials (coatings, stainless steel, copper); foot buttons; operation via smartphone/smartwatch; the app nicknamed “Liftboy” (also for retrofitting); and UV cabin air disinfection called “Wally.”

Wally triggered lively discussions in the chat in which not all questions could be adequately answered due to the novelty of the topic. Regarding the potential health hazard of UV light, participants were referred to an EU Commission publication, ec.europa.eu/health/sites/health/files/scientific_committees/scheer/docs/citizens_uvc_de.pdf.

Edip Kaci from KONE reported on “News from the Escalator.” Specifically, he introduced the EN 115 family for escalators and moving walks, comparable to the EN 81 family for elevators. Design and installation are covered in Part 1 and increasing the safety of existing escalators and moving walks in Part 2, which is due to be published shortly. As for ISO standards for escalators and moving walks, he particularly highlighted the three parts of ISO 25745 on energy measurement, verification and calculation. ISO 18738 deals with the measurement of ride comfort; the revision is currently underway and will be published as ISO 8103 following the new ISO numbering. His conclusion: “The focus is on safety.”

Steffen Braun of the Fraunhofer Institute for Industrial Engineering (Institut für Arbeitswirtschaft und Organisation IAO) painted a far-outlooking picture of the “city of the future” with a focus on the “traffic of the future,” in which he also included vertical transportation. He is exploring how the world will look in 10 years using trend analyses, scenario technique and virtual-reality-based prediction, among other things. He anticipates that people and vehicles will make cooperative decisions. Although the IAO does not yet have any projects on buildings of the future with the elevators and escalators, the institute is supporting building owners with virtual planning tools. Braun expects a change in inner cities currently characterized by high-rise buildings. As a result, vertical mobility is also changing.

Joachim Kalsdorf from AFAG presented the trade fair planning for interlift 2021, which has been postponed to April 26-29, 2022.

Get more of Elevator World. Sign up for our free e-newsletter.