“A Beacon of Engineering Excellence”

Sep 1, 2020

thyssenkrupp Elevator’s new North American HQ, including the tallest test tower in the Western Hemisphere, closes in on completion near Atlanta.

by Kaija Wilkinson

photos by Ron Acord for thyssenkrupp

thyssenkrupp Elevator Vice President of Engineering Steve Allen and your author are among the countless people dreaming of a day when coronavirus isn’t at the forefront of our thoughts. We long for a time when travel can resume, and we’re free to visit and enjoy all corners of our wonderful elevator world. A key, new part of that world is well on its way to becoming reality: thyssenkrupp Elevator’s new North American headquarters, featuring the corporate headquarters (CHQ), business headquarters (BHQ) and the Innovation and Qualification Center (IQC), including the tallest test tower in the Western Hemisphere, at The Battery Atlanta, a mixed-use development aimed at fans of the Atlanta Braves National League Baseball team. The 420-ft-tall tower marked a milestone earlier this year when its concrete core was completed ahead of schedule. Using a process known as slip-form that involves a moving formwork into which concrete is continuously poured to create vertical walls, the core was finished in 57 days.

“It’s a theme we’ve carried throughout this facility: providing unique views of the inner work-ings of our elevators to visitors to the IQC and The Battery Atlanta.”

— thyssenkrupp Elevator Vice President of Engineering Steve Allen

Adjacent to the IQC is the CHQ, while the BHQ is located in nearby Pennant Park. More than 900 employees will work at the three-building HQ when final move-in happens in late 2021 or early 2022. Employees started moving into the BHQ in early spring 2019 (ELEVATOR WORLD, May 2019).

In June, as the pandemic was tightening its grip on the U.S., up to 200 construction workers were onsite at the IQC and CHQ, according to thyssenkrupp Elevator spokesman Dennis Van Milligen. During this time, BHQ office employees primarily worked from home, with “a slow, staggered return-to-office process” ongoing at select locations, Van Milligen said. Construction work continued apace with appropriate safety precautions.

Allen is frequently onsite, monitoring construction progress and supporting the design and construction teams. In addition to the 18 shafts inside the tower itself, thyssenkrupp Elevator’s new center of operations will offer plenty for the public, particularly elevator afficionados, to see and enjoy. Allen elaborates:

“We will have a three-level conference center at the top of the test tower. The lowest of these levels will primarily be meeting space, with a two-story event space above it that serves as an observation area that looks out over Truist Park [where the Braves play]. From there, you’ll have great views of Midtown and downtown Atlanta and, off to the north, the hills and start of the Appalachian Mountains. It will have really nice views of the metro Atlanta area.”

A total of three elevator systems will serve this area (a TWIN system with two cars operating in one shaft, a high-speed gearless [HSG] elevator and a freight elevator). The capacity of each TWIN car and the HSG is 3500 lb. The TWIN’s upper car and HSG unit each travel at 1,200 ft/min, and the TWIN’s lower car travels at 800 ft/min.

Serving all levels of the tower, including internal R&D space, a freight elevator with a 14,000-lb capacity will be used to transport materials throughout the facility.

Allen describes the systems’ notable features:

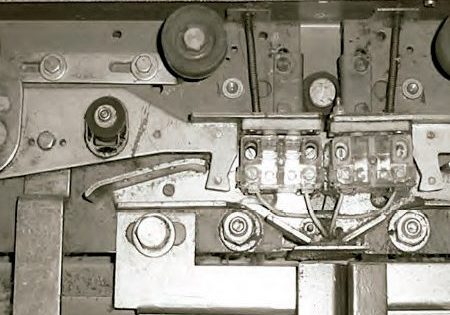

“The TWIN and HSG elevators are going to be installed in a glass atrium on the east face of the tower. This will also be the future home of MULTI. So, you’ll not only have views from the top, but also of materials and machinery in the hoistway — things you don’t normally see. It’s a theme we’ve carried throughout this facility: providing unique views of the inner workings of our elevators to visitors to the IQC and The Battery Atlanta. At the main entrance of the IQC, two escalators which will shuttle passengers from the main, ground level up to level two are customized so some of their inner components are exposed behind glass for public view.”

In July, the installed escalators were surrounded by barriers to protect them from damage from the surrounding ongoing construction. At the same time, two thyssenkrupp Elevator evolution machine-room-less (MRL) elevators were being installed at the IQC, which will have an expansive public meeting area on the fourth floor. Each MRL elevator travels at 500 ft/min and has a capacity of 4000 lb.

Installation of test elevators was to begin at the end of August. In the meantime, thyssenkrupp Elevator was celebrating the progress thus far. Peter Walker, CEO of thyssenkrupp Elevator AG, called completion of the slip-form process an important moment in company history. “It not only symbolizes a brighter future for our organization and the local community, but will be a beacon of engineering excellence that will help transform an industry in need of modern innovations,” Walker said.

About Slip-Form Construction

- Birmingham, Alabama-based general contractor Brasfield & Gorrie is a specialist in the technique and built up the core of the test tower at a rate of more than 7 ft per day.

- Creating the “skeleton” of a structure, the slip-form process is relatively rare in the U.S. but popular in Europe.

- The process was used for thyssenkrupp’s 800-ft-tall elevator test tower in Rottweil, Germany.

- Subcontractor Gleitbau-Salzburg of Austria provided the design, engineering and oversight for the slip-form process.

- Brasfield & Gorrie observes the process provides “superior control over the cost, quality and schedule of a project.”

Get more of Elevator World. Sign up for our free e-newsletter.