A Commitment to Energy Efficiency

Apr 1, 2018

Fermator Group Reduces Energy Consumption of the Door Control System

There are many articles about vertical-transportation energy consumption and its economic impact within the total energy consumed in the world. Using data provided by the International Energy Agency,[1] in 2014, electricity consumption, including gross production plus imports minus exports and losses was 21,962.54 TWh per year.

Several authors[2 & 3] place the energy used in elevator systems at 2-5% of the whole. Taking the average, energy consumed in elevator systems is translated into approximately 768.69 TWh per year. In addition to the energy consumed by the traction system, cabins have other elements, such as lighting, ventilation, car displays (directional arrows, floor indicators, etc.), configurable landing displays or motor-driven doors, also consuming part of this energy.

Fermator Group, as one of the largest mono-product manufacturers of automatic doors for lifts in the world, is making efforts to reduce energy consumption of the door control system, simultaneously improving performance and complying with safety standards and regulations. This article describes the methodology to quantify the energy consumed in the door control system and explains some innovations developed by Fermator Group to reach optimum energy consumption in door operation.

Energy Consumption of Cabin and Landing Door Control Systems

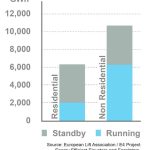

Under normal conditions, according to the elevator use categories presented in VDI 4707,[4] the average standby time per day is 18-23.7 hr. It is important to know how much energy is consumed in the door’s operational and idle states. As an example, Figure 1 shows how the energy is consumed in running and standby time for residential and nonresidential (or commercial) sectors, taking references from the data published by the European Lift Association in its E4 Project[5] for Organisation for Economic Co-operation and Development (OCDE) member countries.

In the residential sector, the energy consumed in standby state represents around 67.16% of the total energy consumed in the elevator system. However, for the nonresidential sector, this percentage decreases by up to 40%. Observing the first figure, it is clear that any action undertaken to optimize the energy consumption in the door system must include measures for the open and closed door states and, separately, when the door cycle is underway.

Stationary Door: Fermator Group Control Position as Smart Solution

In order to understand the steps taken to save energy in either open or closed door positions, it is necessary to quantify the energy currently consumed in doors. “Elevators and Escalators Energy Performance Analysis”[6] proposed a scenario called “Best Available Technologies” to reduce energy consumption when in standby mode. Areas considered include the lighting system, electronic controllers, drive inverter and door operator. The analysis allocated consumption quotas for each of these elements and for the door operator. This share reaches approximately 7.7% of the total consumption. For OCDE members, the energy consumed in door control while in “standby state” in 2016 is shown in Figure 2.

Standby status is associated with the door when in the open or closed positions. Traditionally, to maintain the door positions, the operator applies a motor voltage that results in a shaft torque and, consequently, a force on the belt. This voltage is associated to the “stall current” or torque applied to the open or closed door. In most cases, it is a parametrizable value. One of the main reasons for the energy losses in door control systems is the current consumed to maintain this “stall” position.

Figure 3 shows a cabin and landing door system with its “forces” diagram to illustrate that the ideal situation is reached when FBELT and FSPRING are equal. An imbalance between these forces leads to either loss in the open or closed door position (FSPRING > FBELT) or energy losses by the Joule effect in the drive and motor (FSPRING < FBELT).

Fermator Group has developed software named “Fermator SMART Door Control Position®” that uses algorithms to ensure the terminal door position is maintained automatically, which ensures the correct balance between the landing door closing force and the consequential force of the motor torque. This feature, present in the Fermator Group SMART Drive, is based on the use of space vector pulse-width modulation (PWM) synthetization, combined with proportional–integral–derivative anti-windup controls to avoid possible position oscillations (door “pumping”).

By measurements made during operation in the field, the new Fermator Group software allows a 22-42% reduction in open-door energy consumption. To translate these saving percentages into measurable energy values, if all door systems incorporated SMART, and it is assumed that an operator remains in open-door position 5% of its time, the energy saved could reach 87,705 GWh per year. Obviously, if a door remains in the open position for lengthy periods, the energy saved will be greater. On the other hand, bigger differences between the ideal voltage to maintain the balance between spring and belt forces and the arbitrarily fixed voltage will increase the energy saved by SMART.

Based on data published by the Spanish government,[8] the emissions factor (in kgCO2/kWh) for the “buildings” sector in Spain in 2012 was 0.33. This is the last published value by the National Energy Commission in Spain and will be the factor to be used in the calculations. For the “door open state” only, SMART software would contribute a 28,942.65-T. reduction in the CO2 emitted into the atmosphere per year.

A similar situation to that described for “door open” is also present in “door closed.” In this case, a spring force is present in the clutch, the mechanism used to attach the cabin door to the landing door. A 22-42% reduction in energy consumption was also achieved in measurements made in the field in the “door closed” position.

Door Movement: Fermator Group Space Vector PWM and Constant Torque Angle Control

With the motor operation, efforts made by Fermator Group to reduce energy consumption have focused on the evolution of its control software. Traditionally, open-loop controls with limit switches, or closed-loop controls with

encoder and speed profiles, have both used sinusoidal PWM to synthesize the voltage to the motor. Fermator Group went a step further, incorporating the space vector PWM (SVPWM) as its strategy to voltage synthesizing. Some of the improvements achieved thanks to it are:

- SVPWM is able to synthesize 15% more voltage for the same bus voltage. This allows more varied speed profiles with faster dynamic responses in the case of “obstructions” or reopen signals.

- SVPWM has a lower total harmonic distortion for the whole spectrum of modulation indices. This creates lower Joule-effect losses in the motor and, in turn, results in lower motor working temperatures.

Fermator Group uses constant-torque-angle (CTA) control in its control software. This software ensures that, as described by Dariusz Świerczyński[7] for load ranges below 200% of the nominal load value, CTA control software practically guarantees the maximum torque per ampere. The main improvements achieved by using CTA are:

- Control of the linear force the motor applies to the door panels achieving compliance with requirements of the current regulations, EN 81-20/-50

- Contribution to a decrease in the motor working temperature: from measurements taken in the field, under the same working conditions, the motor temperature with the new control software is 5-10ºC lower.

Looking to the Future

Continuing its policies to create environmentally responsible devices, Fermator Group is developing the “Smart-Devices” line. This strategy will take the evolution of energy-reduction concepts into the mechanical elements that affect electrical consumption. Clutch systems, hanger/track friction, door mass and every other element capable of contributing toward energy savings will be examined, while the company remains focused on guaranteeing safety and robustness.

- Figure 1

- Figure 2

- Figure 3

- The Fermator Group VF7 electronic module

- A Fermator Group Premium PM elevator door

References

[1] International Energy Agency. Yearly report energy consumption,

January 2015.

[2] Harvey Sachs, Harry Misuriello and Sameer Kwatra. “Advancing Elevator Energy Efficiency,” American Council for an Energy-Efficient Economy, Report A1501, January 2015.

[3] Al-Sharif, L. “Lift Energy Consumption: General Overview, 1974-2001,” Elevator Engineering, October 2004, p. 61-66.

[4] Association of German Engineers. “VDI 4707 GUIDELINES: Lifts Energy Efficiency,” May 2008.

[5] European Lift Association-E4 Project. “Energy Efficient Elevators and Escalators,” March 2010.

[6] Carlos Patrão, Aníbal De Almeida, João Fong and Fernando Ferreira. ISR-University of Coimbra. “Elevators and Escalators Energy Performance Analysis,” ACEE Summer Study on Energy Efficiency

in Buildings, 2010, p. 53-63.

[7] MSc. Dariusz Świerczyński. “Direct Torque Control with Space Vector Modulation (DTC-SVM) of Inverter-Fed Permanent Magnet Synchronous Motor Drive,” PhD.D. Thesis, Faculty of Electrical Engineering Institute of Control and Industrial Electronics, Warsaw University of Technology, Poland, 2015.

[8] Ministerio de Industria, Energía y Turismo, Gobierno de España. “Factores de Emisión de CO2 y Coeficientes de Paso a Energía Primaria de Diferentes Fuentes de Energía Final Consumidas en el Sector de Edificios en España,” January 2016.

Get more of Elevator World. Sign up for our free e-newsletter.