Newly formed entity Pronus is betting the lift industry will benefit from lightweight, strong, corrosion-resistant technology.

Pronus, a Hong Kong-registered company, was formed this year by the owners of Sakura Elevator Co. Ltd., half of whom are from the elevator industry and the other half from the composites and construction industry. The company’s purpose is to provide composite solutions to the construction industry. Pronus works with some of the industry’s most renowned composite engineers and manufacturers to guide projects from inception to completion.

Pronus has already formed exclusive partnerships with a number of industry leaders such as Renold, Blain Hydraulics GmbH, Pye London Ltd. and Liftinstituut. Construction consultants such as BK Asia Pacific are set to exclusively promote Pronus’ composite solutions to the construction and elevator industries in the Asia Pacific.

Ultimately, Pronus aims to provide composite solutions and products to all types of elevator, escalator and construction companies worldwide. To support anticipated growth in this sector, Pronus and its partners are investing in a composite production facility in the Philippines, which will be the first of its kind in the country. It will complement the Sakura elevator-manufacturing facility, due to start operation in 2016, also in the Philippines. Within three years, Sakura intends to focus solely on manufacturing for the export of composite lifts and escalators. The certification of all products involved is being worked on closely with the companies’ partners at Liftinstituut.

What Is a Composite?

A composite is the combination of a matrix and a reinforcement. Together, they possess properties superior to those of the individual components. In the case of a composite, fibers provide the reinforcement that fortifies the matrix in terms of strength and stiffness. Reinforcement fibers may be cut, aligned and placed in different ways to affect the properties of the resulting composite. The matrix, normally a form of resin, keeps the reinforcement in the desired orientation. It protects the reinforcement from chemical and environmental attack and bonds the reinforcement so applied loads can be effectively transferred.

Types of Composites

The term “composite” can refer to a multitude of materials. The trade organization Composites UK uses the term (or “reinforced polymers”) to encompass:

- Carbon fiber-reinforced polymers (CFRP)

- Glass fiber-reinforced polymers

- Aramid products (e.g., Kevlar®)

- Bio-derived polymers (or “bio composites”)

Why Use Composites?

The primary reasons composite materials are chosen for components is for their relative lightness, stiffness and strength. CFRP can be five times stronger than 1020-grade steel, while having only one-fifth the weight. Aluminum (6061 grade) is much nearer in weight to carbon-fiber composite though still somewhat heavier. However, a composite can have twice the modulus and up to seven times the strength of aluminum.

As with all engineering materials, composites have particular strengths and weaknesses, which should be considered at the specifying stage. Composites are by no means the right material for every job. However, a driving force behind the development of composites has been that the combination of the reinforcement and matrix can be changed to meet the required final properties of a component. For example, if the final component needs to be fire resistant, a fire-retardant matrix can be used in the development stage so it has this property. Stiffness and strength can also be influenced at the development stage.

A wide range of coatings and paint is available to match appropriate environmental conditions, which can be highlighted in the initial development stage or applied later, should it be decided that a particular property or standard needs to be met further down the line.

The balance of cost, performance and lifecycle analysis should determine whether or not to use polymer composites over alternative structural materials. In the lift industry, there are several areas that could benefit from the use of composites:

- Freight lifts, where composites would allow for the lifting of much heavier loads with smaller traction drives than are currently used with metal cars and frames: in corrosive and hostile environments, composite cars and rails would last much longer than those made of conventional metal. In addition, installation would be easier since lift cars could be flat packed.

- Panoramic cars, where composites would allow architects and designers more freedom to create units of widely varying shapes and sizes: outdoor panoramic cars built of composites would have much longer lives than current metal ones.

- Linear-driven lifts, where use of lighter materials would reduce magnet and energy expenses

- Vacuum, linear or hydraulic home lifts, where composites would allow designs greater flexibility

- Mining conveyances, which are often exposed to salt and water, where the use of composites would extend machine life

Advantages of Composite Trusses

As shown in Figure 1, composite trusses can be broken down and flat packed into manageable sizes that two people can carry through the doors of any building in which access is conventionally impossible or very costly. Such trusses are fully waterproof and can be placed anywhere. Using a composite truss assembled inside a building removes some of the logistical headaches. In addition:

- Composites do not corrode and require very little maintenance.

- Longer warranties on composites can be applied than on steel.

- Costs are lowered on public infrastructure projects, such as those involving underground mass-transit systems in which replacement costs can be astronomical and logistics complex.

- Truss sections can be considerably more compact than those made of steel, allowing for an additional escalator to be installed in metro systems.

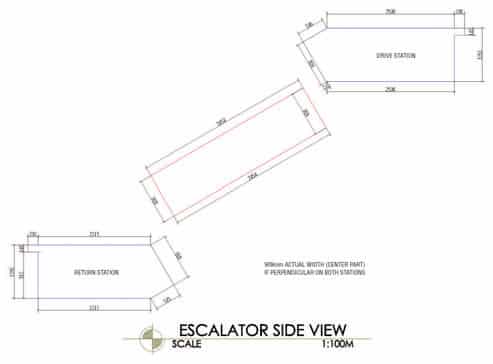

Figure 2 is typical of many underground escalator systems with wide sections between escalators. Use of composites would eliminate the need for such sections. Here, it is possible to put four escalators into a space currently allocated for three. Even more importantly, this could be done without having to close entire units, as is the current practice.

Conventional escalators are completely assembled inside the truss at large factories. They are shipped in large sections after having been fully erected and tested. This requires expensive facilities and potentially costly logistics. With a composite truss, escalator components would be consolidated, installed and tested onsite – no different than if the unit had been modernized.

Pitless Escalator Products for the Future

The next stage is to design a pitless, composite escalator available to the wider, commercial market. Such an escalator would be finished onsite, rather than installed early in construction. To this end, Pronus has begun discussions with Renold and others regarding design. The intent is to have a prototype operational by the end of 2016.

Composite Technology in Hydraulic Elevators

Hydraulic elevator systems are used in low-rise buildings up to six floors. Their applications are primarily residential and freight. Since manufacturing long cylinders is often too costly to be feasible, height is the main physical limitation of hydraulic elevators. Conventionally, structural steel has been used for typical car and frame construction, while high-strength steel is used for cylinder manufacturing. Use of steel structures, however, makes the complete lifting system rather heavy and bulky. Since hydraulic elevators do not use counterweights, they require larger electric motors than traction elevators do. This increases power-supply requirements and energy consumption. Larger motors also increase the size of power units and hassle of installation.

Hydraulic freight elevators, used for heavy goods and/or passenger lifting, are the only feasible solution for lifting weight in excess of 2.5 mT. Car-frame size and weight become intense as payload increases. In addition to the payload in the car, the heavy frame and car need to be lifted, which sometimes requires more energy than the payload. Moreover, heavy car frames increase working pressure and decrease efficiency of the hydraulic system. Table 1 shows approximate energy consumption per pressure increase of 1 bar (14. 5 psi) for different types of elevators.

Composite technology can be used to solve the above shortcomings in hydraulic elevator systems. Composites (in particular, those made of carbon fiber) have significant advantages over most materials in terms of mechanical properties. Carbon fiber has excellent strength and low density and is able to dramatically reduce the weight of hydraulic elevators. The use of composites for the manufacture of car frames and cars will allow the design of lightweight, high-strength elevators. This results in lower working pressures, smaller motors and lower energy consumption.

Hydraulic elevator control valves work above a defined pressure, mostly 8 – 10 bar (116 – 145 psi), which requires a certain weight on the top of the cylinder. This minimum working pressure can be lowered below 8 bar with the use of variable- voltage/variable-frequency-driven elevator control valves. In this case, the complete car frame and car can be constructed from composites. This would permit hydraulic elevators to consume the least amount of energy possible without using a counterweight. Light frame pieces can also be produced in acceptable lengths and easily assembled onsite, eliminating the need for a crane and manufacturing in the pit.

Another advantage can be achieved by manufacturing hydraulic cylinders from composites. Apart from cutting the weight of hydraulic cylinders, composite technology also offers exceptional burst and fatigue strengths. By means of different combinations of fiber and matrix material, tube properties of cylinders can be adjusted. Thus, lightweight composite cylinders with customized material properties offer the greatest flexibility to meet varying customer needs. With composite technology, cylinders up to 380 bar and custom designs with working pressures up to 700 bar are possible.

Composites would also increase buckling strength of rams in hydraulic-elevator systems. Composite cylinders are being produced with two-and-a-half times higher stiffness and approximately two times higher tensile strength than steel. However, carbon fiber’s composite Young’s modulus (a mechanical property of linear elastic solid materials) is as high as 1000-plus gigapascals (a Young’s unit that measures carbon-fiber strength). This means hydraulic elevators could be easily built up to 10 floors, or approximately 30 m.

Carbon fiber normally has a relatively high thermal conductivity of 24 W/mK, but this can be further increased by a specific design that eliminates heat disposal. Moreover, a low coefficient of thermal expansion (three-and-a-half times lower than steel) makes carbon fiber most suitable for telescopic hydraulic cylinders. Composite telescopic cylinders would allow for more compact, lighter and longer stroke cylinders. Transportation and installation of lightweight cylinders can be done easily and quickly, which will have a positive impact on demand for hydraulic elevators.

Carbon fiber composite cylinders and frames in the lifting industry can offer further benefits within tough environments such as mines and ports, where a high corrosion rate requires frequent change of equipment and increases service cost. Corrosion resistance and chemical stability are valuable properties that extend the life of lifting equipment, allowing for inexpensive modernization in the future.

Get more of Elevator World. Sign up for our free e-newsletter.