A Discussion on the Benefits of Modernization

Feb 1, 2025

Thinking beyond replacing single components — meeting demands for increased safety and aesthetics

In October 2024, your author (USB), spoke to Udo Hoffmann (UH), senior vice president Central Europe of Otis, based in Berlin, Germany, about modernization.

USB: Mr. Hoffmann, in 2022, we both talked about the “Big Picture” with a focus on trends in the elevator business in Europe (ELEVATOR WORLD Europe, March-April 2023.) After more than 30 years in the elevator industry — mostly with Otis — you are more than qualified to look back on technology and to develop strategies on (partial) modernization, our topic today. What is your leading thought about this topic?

UH: The whole (elevator) world is talking about modernization because the market for new equipment has been impacted significantly compared to the pre-pandemic era. Furthermore, modernization offers the opportunity to help many people enjoy better environments in their personal and professional lives. Modernizing an elevator system, at the same time, also meets users’ demands for increased safety and aesthetics.

Residential construction is a major sector for elevator companies. Cities in Europe have all been largely completed for a long time. By 2050, nearly 85% of the people in Germany will live in cities and, therefore, in taller buildings. Demographics also play a role: The houses of aging people will not become any lower. Even if new buildings are to be built, as is the case in Berlin, for example, users do not want to wait a long time for new constructions to be completed. All of this provides further impetus for modernization.

From a technical perspective, digitalization is helping with modernization. And AI is also becoming a topic. The aim there is to minimize system failures and elevator servicing times.

Operators and users are also rightly demanding elevators that are energy efficient. Modernization helps to save energy here. However, after years of reduction of energy demand and consumption in elevators, this is no longer a major concern, especially for new elevators — despite funding opportunities.

USB: How many elevators in Europe and the DACH (Germany, Austria and Switzerland) region, in particular, are due for modernization?

UH: At Otis, we speak of an “old system” if it has been installed or running for more than 20 years. Technology and regulations have changed so much during this period that, after this time, you would hardly “recognize” an elevator.

In the industry, we are talking about around 6.5 to 6.6 million elevators in the EU. In the DACH region, there will be around 1.2 million elevators. The potential we’re talking about is huge. There are estimates that around 50% of the EU units are older than 20 years — so, potentially more than 3 million elevators across Europe are due for modernization. It’s worthwhile thinking about modernization from the perspective of the industry.

“The potential we’re talking about is huge. There are estimates that potentially more than 3 million elevators across Europe are due for modernization.”

— Udo Hoffmann, senior vice president Central Europe of Otis

USB: What is the business potential behind this for the Big Four?

UH: At Otis, we see modernization as a growth driver for our business. According to data from the European Lift Association (ELA), the order value for elevator modernization has been growing by around 7% in Europe in the past years. With the installed base growing and aging, we expect that elevator modernization will increase in the years to come.

USB: Does modernization work also fit into the portfolio of small and medium-sized enterprises (SMEs)?

UH: SMEs generally have their own justification. Not every customer wants to put themselves in the hands of a global company. But I think there is a very strong case for customers to consider modernization with a global leader in the manufacture, installation and servicing of elevators. Every modernization solution contributes to greater safety and efficiency — and the worldwide experience of tens of thousands of modernizations naturally makes itself felt in many ways. We also drive technology forward in modernization, including standardization.

By the way, why is standardization often regarded as negative? After all, it advances technology across the board, as we have seen with the energy efficiency of elevators, for example. The standards drive us. We follow them. We have a say in their development. We learn from them. If we are faster than the technical regulations, the cycle starts all over again.

USB: What does Otis offer as modernizations?

UH: Listening carefully to the customer beforehand is very important to us. In the solution, design and/or technology are then always implemented individually according to the customer’s wishes.

However, we have also launched new standard solutions on the market for modernization. To this end, we have put together three packages: Prime, Plus and Pro. This enables us to deliver large quantities quickly. The volume results in lower costs for customers.

USB: What is behind the term “standard package?”

UH: The modernization solutions are scalable. Our Prime package, for example, includes retaining the old drive plus a new control unit. With the Pro package, on the other hand, everything is replaced except for the doors. The new parts are at the same technical level as in completely new systems. As with a motor vehicle, this improves and extends the availability of spare parts.

USB: What timescales are we talking about if all elevators in Europe were really to be modernized?

UH: The percentage of the portfolio that can be completed in which time periods depends on the willingness of customers to invest and the resources available in the elevator companies. Employees might become a bottleneck here. The “baby boomers” are currently retiring in large numbers. We have several training centers in Europe where we train technicians and offer a dual study program (In Germany, a combination of apprenticeship and university studies). Training and further education take place both face-to-face and digitally.

Today’s elevator technicians need more knowledge of electronics and electrics than in the past. The trend is toward cellphone technology when they are on-site. AI tells them the model of the system and how it can be optimized via modernization. For new systems, this data is already available. In the past, the customer wanted to see the technician at work; today, the system must be “only” operational.

USB: What are the benefits for operators and passengers?

UH: One of the triggers for customers, usually operators, for undertaking a modernization is increasing and longer outages of older systems, for example, because the availability of spare parts is decreasing. Users then start to have doubts about the reliability of the elevator; they may even feel unsafe when using it. Or they want to improve sustainability and/or offer more experiences or information in the cabin. The plannability of a modernization makes the decision easier.

“It is crucial to comply with the latest safety standards when modernizing. This includes the control system and the associated digital provision of the required data.”

— Udo Hoffmann, senior vice president Central Europe of Otis

USB: Can you please say something about the costs?

UH: A cost-benefit analysis is essential. For a modernization, this includes factors such as downtimes, repair costs and investments. So, the question would be if the continuous costs of repair outweigh the benefits of a replacement — as, for example, with a new heating system. In the case of a replacement, there would also be ancillary construction costs. For example, the standard shaft dimensions of the 1950s no longer match those of today. Costs are always an individual consideration for each system.

USB: Is there any financial funding available for this?

UH: The funding landscape is complex and changes quickly. As far as I know, there are currently approaches for energy efficiency, refurbishment, accessibility and emergency call communication. Of course, we support our customers with such requests.

USB: What are the main technical aspects of modernization?

UH: It is crucial to comply with the latest safety standards when modernizing. This automatically includes the control system and the associated digital provision of the required data. Emergency calling is often added to this. The combination of these two components can contribute to faster remote intervention in the event of trouble.

USB: And in the case of partial modernization, respectively the replacement of components, which parts are mostly affected and why?

UH: A decision is often made as to whether the motor must be removed because it is broken, or a new motor can be installed during modernization. This involves replacing the ropes with flat belts and the traction sheave. This means less energy is consumed, no more oil is needed to lubricate the ropes and the system runs more quietly overall. I have already indirectly mentioned the front control elements like buttons and displays so that all data for the modernization can be provided in conjunction with the control system.

But be careful! Thinking only about replacing single components is overly simplistic. Certainly, you can replace only components, but you won’t get the full benefit of the modernization. Of course, for cost reasons, you might only refurbish the inside of the cabin, but the out-of-sight technology is more important. Therefore, I would advocate proceeding step by step, depending on the financial possibilities.

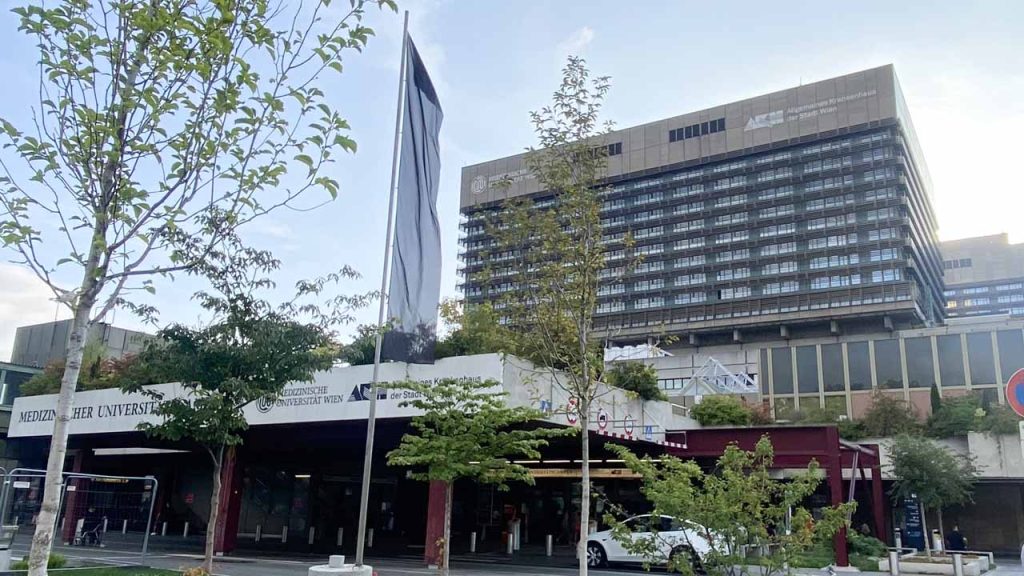

When Otis modernized the Empire State Building in New York City, U.S., there was an investment plan that extended over several years of renovation during ongoing operations. The same applied to the modernization of Vienna University Hospital (AKH Wien) in Austria, one of the largest hospitals in Europe.

USB: How is such a modernization planned and by whom?

UH: Otis plans the modernization together with the customer. We have the appropriate experts available in-house for this purpose. Our field team is also involved. For complex modernizations, engineering and/or planning offices are often involved, too. They provide an additional perspective. Architects, in particular, are happy when they don’t have to worry about the technical details.

USB: How long does it take and how does it proceed on-site?

UH: A hospital complex, where operations cannot be disrupted under any circumstances, naturally requires much more detailed planning than a multi-story residential building. In this case, it is sufficient for Facility Management to inform the tenants once the date has been agreed upon with the customer. The longer the lead time, for example, planning now in October for next June, the more convenient the procedure is for everyone involved. If it has to be done faster, for example, because a system is not working anymore, we will work with the customer to find a suitable solution.

USB: Do you have any current examples of modernization projects from your company?

UH: Oh, yes! Last year, we announced two extensive modernization projects in Germany on the Otis’ LinkedIn account about the Frankfurt Prisma Building and the Hannibal II residential complex in Dortmund with more than 400 apartments.

USB: Thank you, Mr. Hoffmann, for this forward-looking interview.

UH: Thanks to EW for dealing with the topic of modernization in more detail. And to all readers: Please understand elevator modernization is a booster for economy, safety and comfort, and not as a trigger for a lot of additional work and costs, as well as construction noise.

About Otis

Get more of Elevator World. Sign up for our free e-newsletter.