A Golden Anniversary

Feb 27, 2023

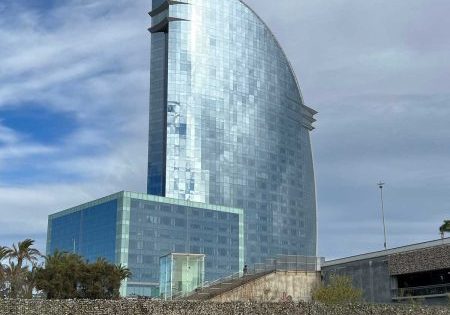

Terry Lifts Chairman Peter Morrey celebrates 50 years and counting at the top of the manufacturing business in Cheshire.

Peter Morrey, chairman of Terry Lifts, joined the company as general manager in 1972, and, following a small initial investment, went on to acquire 100% of the business. How did this opportunity come about? “Serendipity,” he said.

Since the age of 18, in his spare time, Peter ran a car repair workshop and small equipment hire business in Holmes Chapel — his birthplace — which is around 10 mi. south of Knutsford where Terry Lifts is based. His employment was with AEI/GEC — the U.K.’s biggest heavy engineering group — in Trafford Park, Manchester, then the largest industrial estate in Europe. At the same time, he obtained engineering qualifications at Salford University and John Dalton College, Manchester.

He then moved to Nuclear Power Group Ltd. in Knutsford as a research engineer on thermodynamics, reactor cooling and heat transfer. There, he earned a two-year diploma in management studies on day release — the forerunner of the MBA. On that course, he met an electrical engineer called Chris who broke a part of a tool while repairing his Hillman Imp. An old-timer in his department told him of a backstreet engineering firm in Knutsford which may be able to help. Chris called in there on his lunch break and met Eric Terry, who said, “Call in on your way home, and the parts will be ready.” Chris did so, asking the price, and Eric said, “No charge!” They got chatting, and it turned out that Eric was looking for a successor: He was around 68 at the time.

Peter said:

“The following Monday, Chris told me about this potential opportunity, so I telephoned Eric and had one of the strangest conversations of my life — he didn’t waste words, or anything else for that matter. At that time, I was unsettled in my career, as successive Governments were prevaricating over nuclear power station policy (little has changed). So, I went to meet Eric, (this was in March). Somehow, we gelled, and I went to the business every Saturday morning to get a feel for it and committed to join him in September.

“I joined as general manager (GM), took a considerable drop in salary, and had a successful first year, at the end of which Eric gave me a significant bonus (a wedding present, in fact), and I invested my earnings from the ‘spare time’ business and a small legacy from my grandfather for 20% of the shares. Over the next eight years or so, I acquired 100% holding.”

When Peter first joined the business — known then as Heat Pumps and Engineering Ltd. — there were two directors: Eric Terry and Honor Martin. As well as doing the books, Honor operated a wartime capstan lathe. She was the best in the business. Peter was there as GM with five production staff and a subcontracted builder/installer. His first job on day one was to run off 200 special bolts on a capstan lathe and deliver them to GEC Traction Ltd. the following day.

“I had to run the whole show, from product design, R&D, sales and surveys, installation, servicing, production, purchasing, factory maintenance, HR, health and safety, feeding the works cat … essentially, everything,” Peter said.

The Birth of Terry Lifts

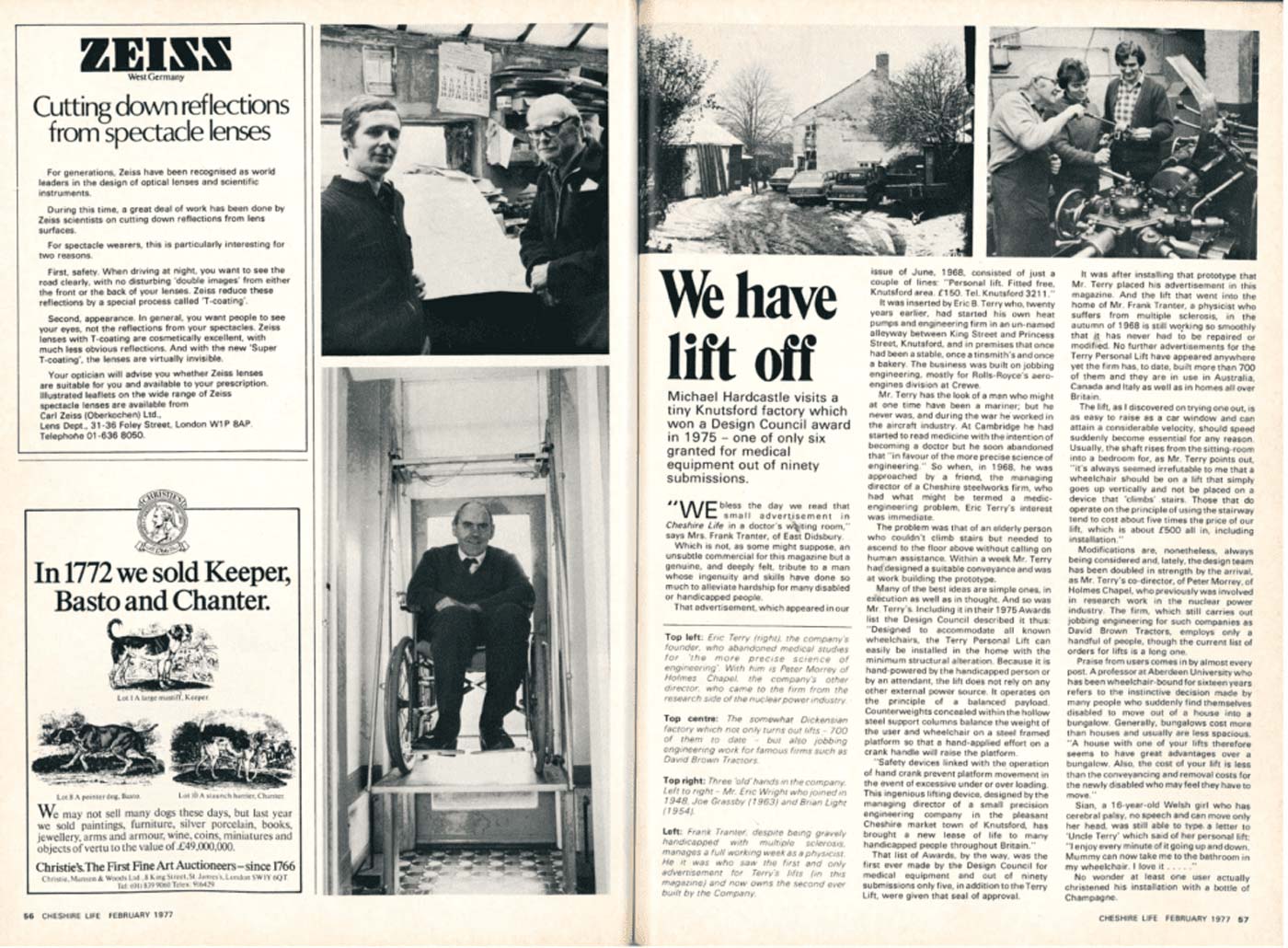

Prior to Peter’s arrival, the business, established in 1947 by Eric, carried out subcontract engineering work for companies in the Manchester area. In subsequent years, it secured prestigious contracts for the likes of Rolls Royce, but it was the innovation and installation of the first counterbalanced stairlift in 1968 which marked the start of a new era for the company and, later, Peter himself.

The idea came to Eric purely by accident. The mother of a major customer at the time had a problem getting upstairs. Eric was given the challenge and, within a week, had rigged up a simple counterbalanced stair lift. This product led to the development of the Terry personal hand-operated through-floor lift. Peter said:

“When I arrived, the company had installed around 50 stair lifts and through-floor lifts, but they were very basic and relied heavily on the user operating them correctly. My task was to add refinements and mechanisms, such as locking devices, safety gear and interlocks, to make the product safe to use — quite tricky when everything must be done mechanically rather than just fitting a switch.”

With the product now “tamed,” in 1975, the company, by then Terry Lifts Ltd., received a Design Council Award for medical equipment gained for the design and development of the Terry Personal Lift. HRH Prince Philip, the late Duke of Edinburgh, presented Eric and Peter with the award at Filton Aerodrome in Bristol under the wing of the Concorde, which had not yet flown at this time. “This was a significant early achievement,” Peter said.

He added:

“Alongside the hand-operated, counterbalanced lift, we also designed a unique air-operated step lift in 1974. I got the idea after reading an article on aircraft being recovered from runway overshoot using airbags and built the first prototype lift using a second-hand vacuum cleaner and a bin liner.”

The Dawn of Hydraulics

The company went on to manufacture thousands of air-operated Terry Step Lifts until the drive system was changed to hydraulic in 1998. Owing to the rise of electrically-driven (rope-driven), domestic, through-floor lifts in the late 1980s, demand for the hand-wound product started to decline, and the company realised change was needed to stay competitive.

However, there was no challenge in producing an “also-ran,” so a direct-acting hydraulic drive system was adopted. It was the launch of the Harmony in 1988 which set the company’s trajectory and remains a significant milestone for the business. Peter said:

“The Harmony was a real game-changer for Terry Lifts. It was the first of its kind and has gone on to become a global best-seller. Benefitting from upgrades and developments over the years, the Harmony is still our most popular product.”

Export Sales

Terry Lifts products, in particular the Personal Lift, had been exported since the mid-1970s. The early exports went to Norway, Australia and Israel. Today, the company exports to more than 30 countries. Peter said:

“We are incredibly proud of our global reach and the longevity of many of our partnerships. P.R. King & Sons has been our sole agent in Australia for 40 years, for example, and is one of our largest single customers. In that time, they’ve installed around 1,000 Terry products across the country, most of which are still in service.”

Export sales remained strong during the pandemic, helping to stabilise the business, particularly during those first few uncertain months. “P.R. King & Sons is a good example of this,” Peter said. “Their sales rose 37% in 2020 compared to the previous period. Despite restrictions, shipping delays and lockdowns, they ordered a substantial number of home, platform, portable and step lifts that year.”

So, too, South Korean export partner, UD Center, which ordered many portable platform lifts during the same period. More than 70 units were shipped between January and September 2020. Interest grew as the South Korean Government imposed regulations for suitable access and disabled facilities in public buildings. The portable platform lift, a development of the Step Lift, provides a flexible solution where wheelchair access is required on a temporary basis.

Problem Solving

As an engineer, Peter’s main interest lies in problem solving. “Product design and development have always been my focus,” he said, “working on the basis that ‘build a better mousetrap, and the world will beat a path to your door.’”

This passion has led the company to design and launch a variety of successful and industry-respected lift products. The “classic” screw-driven Melody 2 platform lift was introduced in the early 1990s and was superseded by the hydraulic Melody 2 in 2010, and then the Melody 3 in 2014.

The airbag step lift was replaced in 1998 with the HSL (hydraulic) low-rise step lift and the original concept Melody 1. The Melody 1 underwent a facelift in 2006 to bring it in line with the newly released TSL 500 and 1000 range of low-rise lifts.

A special heavy-duty step lift, TSL 1100, was created for the Australian market in 2011. Most significantly, the Lifestyle home lift was launched in 2012. This compact, fully enclosed, two-person domestic lift enabled the company to extend its reach beyond its traditional customer base. Today, this lift is enjoyed by people of all ages and abilities across the globe. The Harmony range also received a boost with the introduction of a fully enclosed version, the Harmony FE in 2017.

A New Era

Today, Terry Lifts is being run by Managing Director (MD) Dave Allen. At 75, Peter was very happy to move on to the role of chairman, and he handed over the reins to Dave in 2020. The pandemic and living remotely — Peter and his wife, Sarah, who has been an instrumental part of the business for 25 years, live in the Channel Islands — made it difficult to continue as MD. He said:

“We had made some significant changes to the business pre-pandemic — improving efficiencies and curtailing loss-making initiatives — so it felt like the right time to step aside and allow our young, dynamic management team to lead the business into a new era.”

Terry Lifts came through the pandemic “with flying colours” and the aim, now, is “to grow sales steadily with the finest, innovative products on the market together with top-class support to our agents, dealers and end users.”

Looking back on his 50 years with the company, Peter said this in closing:

“I have been very privileged and proud to have headed up the company for the last 50 years and to see it grow into the successful business that it is today. I have had an incredibly rewarding career with lots of fun and job satisfaction. The lifts we have produced have improved the lives of more than 50,000 people.

“A business’s biggest asset is its employees, and its success is down to them. I am proud to say that we have had some incredible, loyal and long-serving people over the years but never better than the team we have today. I’ve been the chief engineer — the guy who does the concepts, but it’s everyone else who takes that to fruition. A real team effort. My sincere thanks go to all our customers, our management team and our staff.”

Get more of Elevator World. Sign up for our free e-newsletter.