A History of Elevator Doors

Dec 1, 2016

The 75-year-long evolution of the elevator door featured various designs often driven by the need for greater safety.

The modern elevator door is the product of approximately 75 years of invention and refinement. The ballet-like mechanical system of car and shaft doors, which open and close as perfectly integrated components, has become an accepted – and expected – feature of elevator operation. Modern elevator doors also provide a profound sense of security for passengers waiting for and riding on elevators. In fact, unless the elevator system features the shaft in some way, such as in an observation elevator, most passengers are essentially unaware of its presence and inherent dangers. In most settings, the elevator is a kind of magic box, with sliding doors that open and close upon entry and open and close upon exit, with passengers magically transported to their destinations.

The development of the modern elevator door is primarily a 20th-century story. While inventors and industry members in the 19th century were equally concerned about safety, their door designs often reflected the relative infancy of the elevator industry, as well as, occasionally, the unique mechanical imagination of this period. The following door designs derive from a survey of 19th-century elevator patents, the designs within representing a diverse set of solutions.

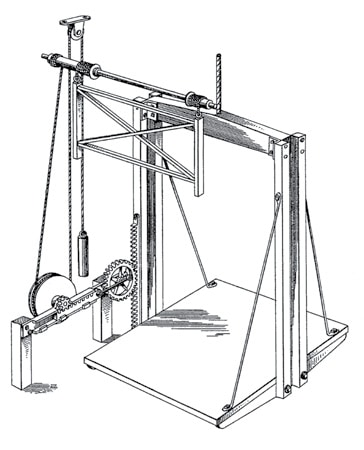

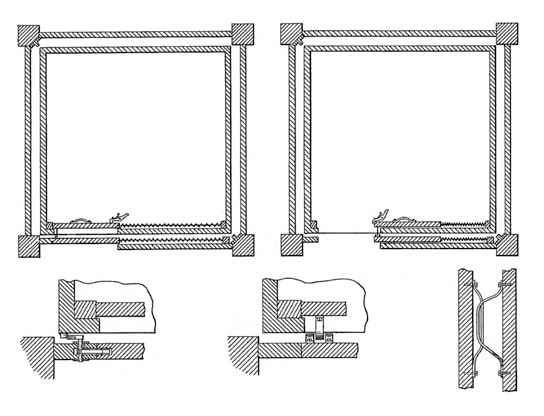

The history of 19th-century elevator doors includes both doors and gates, with the latter typically employed in factories or other industrial settings. Most elevator gates were normative in their design and operation, with the gate operating along a vertical path (Figure 1). However, some gates employed a more inventive solution, such as a design from 1882 that operated like a railway-crossing arm. It featured a horizontal bar that was weighted at one end, and, as the bar was raised, the vertical pickets collapsed against it, clearing the way to the platform (Figure 2). Elevator gates were designed to prevent workers from falling down the shaft or coming into contact with moving platforms or counterweights. It is important to note that the gates guarding access to the shaft had no counterparts on the open elevator platform. Although this absence and apparent lack of concern for the safety of workers who accompanied freight or materials during their journey could be attributed to the freight elevator’s utilitarian setting, car doors were also often absent from passenger elevators.

Cyrus W. Baldwin’s 1884 “Device for Operating Elevator-Doors” employed a typical hinged door to access the shaft. Baldwin’s design addressed two safety concerns: ensuring the shaft door could not be opened unless a car was present and ensuring the car could not move while the door was open. The former concern was addressed by an interior door latch only released when the car was present at the landing. The latter was addressed by a clamping device attached to the hand-rope controller. When the car stopped at a landing, opening the shaft door caused the clamp to grip the hand rope such that it could not be used. Baldwin’s design was primarily intended for use in residential settings, and, because these settings did not employ elevator operators, he provided a means for starting and operating the car from any landing. This was accomplished by two hand ropes located adjacent to the elevator door (Figure 3). The successful operation of this system would have required that the door have windows to allow the user to be able to determine when to stop the approaching car.

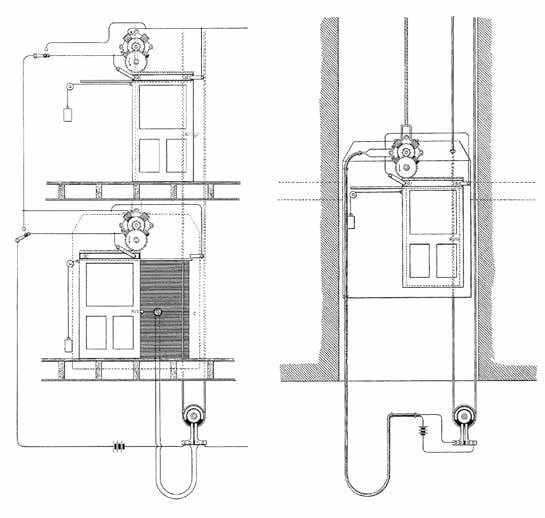

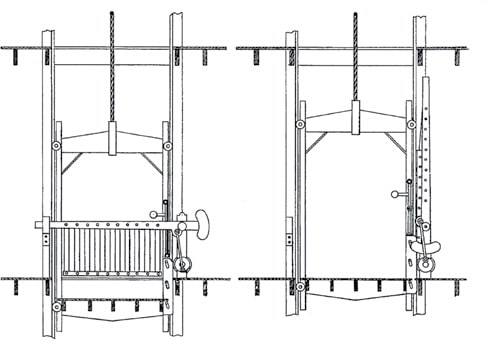

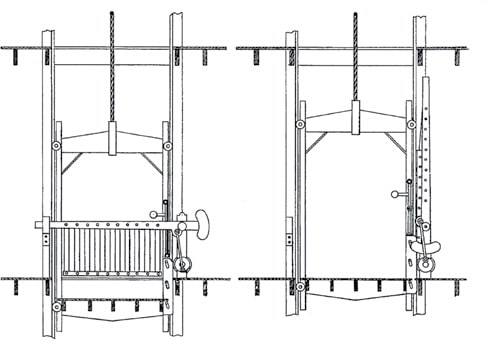

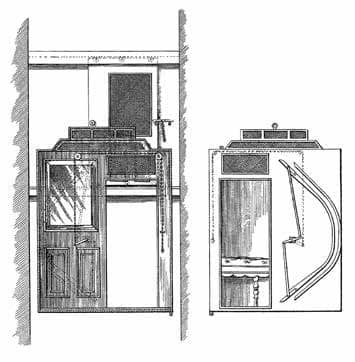

Baldwin’s design required the elevator user to open and close the shaft door. John G. Meisner’s 1885 “Automatic Elevator-Gate” design sought to eliminate this action on the part of the operator, which he described as “not only annoying, but requiring considerable time and labor.” Meisner employed sliding shaft doors that featured a friction roller at the center of the door near the inside edge. The car was equipped with a “grooved guideway” that engaged the door roller (Figure 4). As the car began to pass by a door, the roller would enter the guideway, which resulted in the door sliding open as the car came to a stop. When the car departed, the action was reversed, with the door sliding closed as the car left the landing. If the operator did not want to stop at a given floor, he would pull a chain in the car that shifted levers located at the top and bottom of the grooved guideway. This action prevented the door roller from entering the guideway. Each door was also equipped with an interior latch released when a car engaged the door roller. Although Meisner’s design relieved the operator of the “annoying” job of opening and closing the shaft door, the automatic operation of the door while the car was still moving could have presented serious potential safety concerns for passengers.

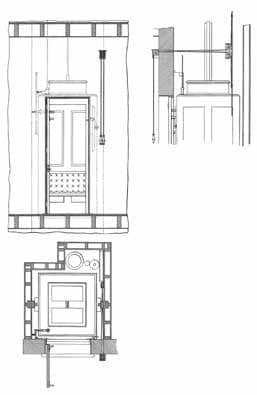

William E. Nickerson’s 1889 “Device for Operating Elevator-Doors” design not only placed the burden of door operation on the elevator operator, it doubled the amount of work required, because his scheme also included car doors. Like other designs, Nickerson’s scheme featured an interior shaft-door latch that was released when a car was present at a landing. However, he also included an interlocking system that linked the car door with the shaft door such that, when the operator pulled the car door open, the shaft door also opened. The doors were held open by a catch located in the car. They also featured springs that automatically pushed the doors closed when the catch was released (Figure 5).

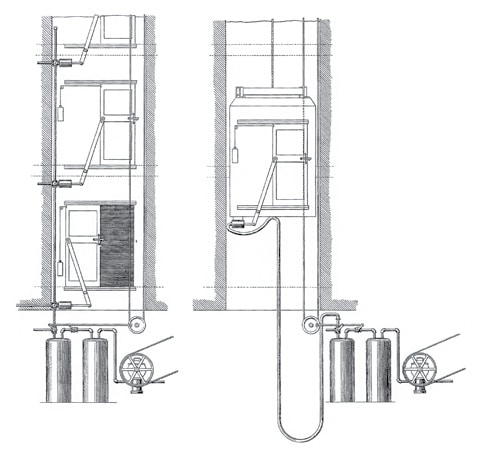

In 1892, Charles N. Judson patented a design that also featured car and shaft doors. The rationale driving his work was stated as follows:

“It is well known that elevator shafts and cars are a great source of danger to the public from the fact that through the negligence or carelessness of the attendant or through faulty construction, the doors or gates of such shafts or cars are either left open or are permitted to open by the action of gravity while the elevator car is in motion and away from a landing place, and thereby, persons are permitted to fall through the shaft and either [be] killed or badly injured.”

Some of this criticism appears to be aimed at automatic designs like that proposed by Meisner in which the doors operated while the car was moving. Judson’s solution was an automatic system of operation connected to the hand-rope controller, which opened the doors only after the car had stopped at a landing. The operation of the doors was powered by:

“. . . a vacuum pump connected by means of one or more vacuum chambers and pipes with several cylinders, pistons, piston rods and levers, respectively located immediately adjacent to each of the several doors through the length of the shaft, as to close any door in the shaft or car that may be open whenever the controlling device of the elevator is manipulated to cause the elevator to rise or descend.” (Figure 6)

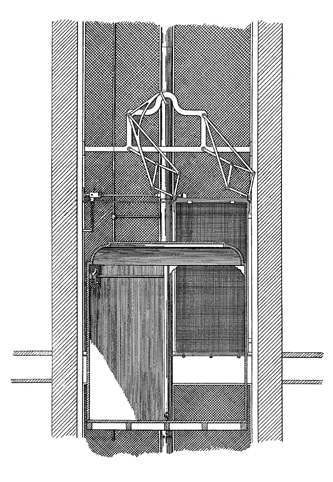

However, Judson did not provide a convincing description of how he proposed to synchronize the operation of the car and shaft doors, and it is doubtful his system would have an operational speed equal to manually operated doors. Interestingly, Judson also patented a version of his design that employed electric motors and a rack-and-pinion system to open and close the shaft and car doors (Figure 7).

The final door system examined was patented by Ephraim A. Haldeman in 1896: “Device for Automatically Operating Elevator-Doors.” Haldeman characterized his design as suitable for use on “that class of elevators used in office, apartment and other buildings.” The purpose of his invention was to “provide an attachment for automatically opening and closing the elevator doors.” The “attachment” was a series of levers that moved a sliding elevator shaft door. The operation of the system was initiated by the elevator operator, who was required to step on a foot pedal in the car (Figure 8).

The complexity of Haldeman’s system was typical of many 19th-century designs. Although this complicated scheme may have resulted from the inventor overthinking the mechanical solution to this problem, the lack of modern components — such as reliable small-scale electric motors — doubtless hindered the design process. A future article will examine the impact of developments in electric-motor design on elevator-door design and the invention of modern door operating systems.

“Automatic Elevator-Gate” (U.S. Patent No. 319,292, June 2, 1885): (l-r) section through car and shaft (friction roller and interior door latch visible on shaft door) and elevator car elevation (grooved guideway adjacent to door opening)

Get more of Elevator World. Sign up for our free e-newsletter.