History and insight into the development and state of ISO standards and what must be supplied to owners when a new lift is handed over

This article was first presented at the 2018 International Elevator &Escalator Symposium in Istanbul. For more information on November 2019’s event in Las Vegas and to participate, visit www.elevatorsymposium.org.

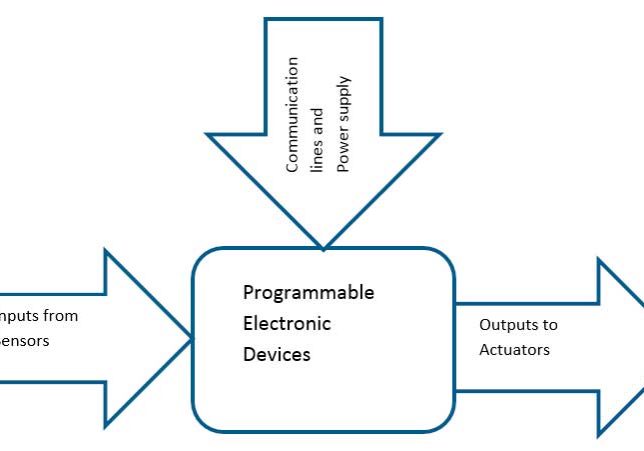

For many decades, until the mid 1990s, the available prescriptive safety standards hampered almost any important innovation for lifts and many other types of machinery. Then, toward the end of the 20th century, the “New Approach” European Directives, focused on Essential Health and Safety Requirements (EHSRs), paved the way to any possible innovation that claims to be compliant with such EHSRs. Before this change, most lifts were almost the same: the skills to perform appropriate maintenance and repairs could be easily transferred, directly, from the master to his service teammate, while doing their daily work. Today, more productive working systems are increasingly based on a single operator, and the continuing innovation, so rapidly implemented in the new lifts, requires a completely different approach to ensure that these new lifts are easily maintained in a safe and reliable running condition. This document, by analyzing the problem of “why and how” to make available the rapidly evolving know how, necessary to face the endless proposals of new features or types of lifts, intends to suggest some practical solutions for the near future.

Introduction: The Historical Human Approach to Standards

There seems to be a very interesting link between the development of new instruments or standards and the subsequent research by humans of economic benefits based on the use of such innovative means. This trend has been confirmed along the centuries and appears to be even stronger today. It is no surprise to notice, at least in the last couple of centuries, the haste to present patent applications relating to an increasing number of different articles, ranging from new or improved devices, to production tools or processes, often linked to subjects for whom a standard is under development. The products covered by patents might also be traded by third parties based on an agreement with the patent owner. This agreement normally involves royalties to the patent owner.

Although we could consider the exploitation of patents, intended as protection of intellectual property rights, a legitimate source of economic benefits, it is surprising to see how many times the implementation of some standards could also provide economic benefits to some who contributed to their development. This would not only be due to the higher quality and better performance of those products that conform to specific standards, but also because the specific standards would somehow favor the products of some of the contributors.

So, it is not surprising that, in the initial phase, the practical implementation of the standards for the various products taken in consideration was not as widespread as expected. And, it is not surprising that, for the same type of products, there were many different “standards,” probably developed by different contributors.

The event that eventually triggered the race for the development and a broader implementation of standards as we know them today occurred in 1904, on the dramatic occasion of the Great Baltimore Fire that raged on February 7-8. Most firefighting equipment was patented by the manufacturer. Despite any efforts to establish standards, few cities saw any reason to adopt them, while the OEMs did not want competition.

The disaster brought into focus the lack of national standards in firefighting equipment, which was, indeed, one of the major reasons for the long duration of the fire and the extent of the damage. For example, the U.S.’s National Bureau of Standards estimated there were more than 600 different sizes and variations in firehose couplings across the country. Manufacturers used the variations as a competitive advantage, making it difficult for fire companies to switch vendors.

Importance and Development of International Standards

In 1905, a committee of the National Fire Protection Association established a national standard for hose couplings and fire hydrants. In 1901, just a few years prior to the Great Baltimore Fire, the world’s first national standards body was established in London as the Engineering Standards Committee (now BSI Group). Similar national bodies were established in other countries after World War I. In October 1946, delegates from 25 countries

met in London and agreed to create a new global standards body, the International Organization for Standardization (ISO), which began operations in February 1947. ISO remains the international organization with the most members (more than 160) representing different countries.

In general, the deliverables of the technical standardization activities concern “interface standards,” which specify how products interconnect with each other, or “safety standards,” which prescribe the characteristics necessary to guarantee that a product or process is safe for humans, animals and the environment. The standards are voluntary until adopted by a government; then, they assume the role of “technical regulations” that are mandatory.

The Convergence of Safety Standards for Lifts

In 1979, ISO started a new technical committee (TC), ISO TC 178, with the scope of dealing with the preparation of standards for lifts, escalators and moving walks. Two years later, TC 178 decided to investigate the possibility of achieving a convergence of the safety requirements of the existing standards for lifts. At that time, there were at least 10 major ones present in the world.

This first major objective led to the creation of a specific Working Group (WG), ISO TC 178/WG 4, in 1983. Its initial scope was analyzing and comparing the safety requirements of the three major safety standards for lifts: those concerning North America, Europe and Japan. It was initially decided to analyze a selection of the requirements for safety components, considered as a set of easier references, to identify an acceptable set of amended versions that could be commonly agreed upon as suitable replacements for the standards being examined. The same exercise was then extended to the other major parts of the standards. This led to the 1990-1996 publication of ISO/TR 11071-1 Comparison of Worldwide Lift Safety Standards — Part 1: Electric Lifts and ISO/TR 11071-2 Comparison of Worldwide Lift Safety Standards — Part 2: Hydraulic Lifts, two progressively evolving Technical Reports concerning the “agreed-upon points” based on the comparison of the worldwide lift safety standards.

The Development of Worldwide Lift Safety Standards

In the meantime, especially in Europe, concern was growing on the negative effects of the constraints to the development of products implementing newer technologies, because of the need to comply with the requirements of the current safety standards, or technical regulations, for the various related products. It was recognized that the speed with which new technologies were becoming available on the market was much faster than the introduction of these new technologies in the revision of standards/regulations for products that could have benefited greatly from their rapid utilization.

The standard writers started to consider specifying the safety requirements that could be identified by the “effect of their implementation,” rather than the “prescriptive specifications” normally present in the text of traditional safety standards and technical regulations. This innovative approach to the development of “performance-based” standards was considered flexible and effective by most experts in the standardization community, who identified this proposal as leading to the preparation of standards open to innovation, as opposed to the prescriptive standards.

This concept of performance-based standards was also considered by the World Trade Organization (WTO) as suitable for the “global relevance standards” being introduced in the WTO’s trade negotiations. It culminated in the WTO “Technical Barrier Free Trade” (TBT) Agreement, signed in 1994 by most world states. The subsequent amendments to the TBT Agreement established the importance of performance-based standards achieving (under “specific conditions” for the preparation of mandatory technical regulations, conformity assessment procedures and voluntary standards) the status of global relevance standards. These are considered the most appropriate tools for implementing global standards that could be accepted by all WTO members.

A further development of the TBT Agreement, due to subsequent amendments, had almost imposed an obligation on ISO (within the requirements to ensure international standards ISO develops, adopts and publishes are “globally relevant”) to make some WTO “specific conditions” established in November 2000 mandatory. The following appear in Annex 4, paragraph 10 of the Second Triennial Review of the Agreement, which state a globally relevant standard should:

- Effectively respond to regulatory and market needs (in the global marketplace)

- Respond to scientific and technical developments in various countries

- Not distort the market

- Have no adverse effects on fair competition

- Not stifle innovation and technological development

- Not give preference to characteristics or requirements of specific countries or regions when different needs or interests exist in other countries or regions

- Be performance based, as opposed to design prescriptive

In connection with the investigation and preparation of the convergence of safety standards for lifts, the publication of ISO/TR 11071-1 and ISO/TR 11071-2 highlighted discrepancies in the lift safety standards. So, it was agreed that ISO TC 178, supported by such a large and efficient representation of international lift experts, would need to accept the challenge of developing a performance-based safety standard for lifts: an ISO publication that would establish the Global Essential Safety Requirements (GESRs) for lifts (elevators). This project, called “Global Barrier- free Trade” for lifts, was based on the preparation of a series of standards that would also include technical specifications that provided indications concerning the activity and possible mutual recognition of Conformity Assessment Bodies and Conformity Assessment Procedures. The first document was the performance- based safety standard ISO TS 22559-1. For it, an evaluation based on risk assessment (concerning almost all the possible hazardous situations) identified nearly all the necessary provisions for a new lift product to be sufficiently safe.

These performance-based safety provisions are not precise indications such as the ones normally listed in prescriptive standards (e.g., dimensions, speed, torque, strength, weight, pressure, acceleration and capacity). These new provisions are descriptions of “what the lift needs to be fitted with” or “how it has to behave” so it will not endanger persons, goods and/or the surrounding environment.

This was very important work by the best available lift experts at the ISO meetings, both at centralized and regional levels. This organic and reliable set of GESRs is suitable to guarantee the expected level of safety for lifts being placed in any market and is very detailed. Their text was finely tuned to match the wording present in the various lift safety standards: almost all hazardous situations that might affect a newly installed lift were considered and deeply investigated.

The evaluation performed for the preparation of ISO TS 22559–1 was focused on the level of safety to be guaranteed for a new lift. It also considered all possible hazardous situations. After the publication of ISO TS 22559–1, the regional study groups and ISO TC 178/WG 4 had the task of comparing the requirements provided by ISO TS 22559–1 with those in the existing local lift safety standards and technical regulations. The intention was to ascertain that the GESRs for lifts of this new ISO document were at least equivalent to those provided by all the existing lift safety standards.

The publication of the Machinery Directive in 1989 and of the Lift Directive in 1995 urged ISO to develop a performance-based safety standard to replicate and, possibly, widen the set of EHSRs provided in Lift Directive 95/16/CE Annex 1. One of the major tasks was the comparison of the GESRs specified in ISO TS 22559–1, with this EHSR applicable at the time of the investigation. This proved to be a very lengthy process and is still open for further verifications and possible amendments.

The “New Approach” European Machinery and Lift Directives

At the end of the 1980s, the European Commission started considering specifying safety requirements in the European Union (EU) Directives that might be identified by the effect of their implementation. The aim was to provide European producers with a good and safe opportunity to develop new products technically more advanced than those supplied by producers in countries outside the European Common Market.

This concept was further developed and soon led to the publication of “New Approach Directives” in which there were mandatory annexes (performance-based technical regulations) that specified the EHSRs to be implemented to satisfy the level of safety expected. The first Machinery Directive was most recently recast as Machinery Directive 2006/42/EU. EHSRs are specified in its Annex 1, which is one of the “technical regulation” parts of this directive. Its sixth chapter listed the specific additional EHSRs that concern “machines lifting persons.” These EHSRs are also applicable to lifts, as clearly indicated in Lift Directive Annex 1. They are well-structured and a clear compendium to eliminate or sufficiently mitigate the more likely possible hazards in newly installed lifts. It does not pretend to fully list all possible hazardous situations in detail.

Regarding other possible hazards that may not have been included, it immediately prescribes a further mandatory risk assessment that must always be carried out at the beginning of the design by the installer. The very first item highlighted in Lift Directive Annex 1 makes it mandatory to implement all applicable EHSRs listed in the annex to the current Machinery Directive, specifically:

“1.1. Application of Directive 2006/42/EC

Where the relevant risk exists and is not dealt with in this Annex, the essential health and safety requirements of Annex I to Directive 2006/42/EC of the European Parliament and of the Council (1) apply.

“The essential health and safety requirements of point 1.1.2 of Annex I to the current Machinery Directive apply in any event.”

Point 1.1.2 is clearly referring to the Principles of Safety Integration as specified by many ISO guides for standardizers, such as the ISO/IEC Guide 51. They are focused on the design of the product and the implications arising from its current use and foreseeable misuse. They also establish the priorities of the risk-reduction measures that, according to the guide, shall be implemented in the following order:

- Inherently safe design

- Guards and protective devices

- Information for end users

Annex 1 to the Machinery Directive, in the section concerning “current use and information for the users,” provides a fairly long list of detailed requirements that specify the type of information to be transmitted to the owner of the machine in a way never done before in such a specific and clear way. The reason for this is the fact that this New Approach Directive allows the direct implementation of new technologies, well before they are common in the market. So, there is a need to provide the necessary information to allow the owner of the machine to have everything necessary for the correct and effective maintenance of the machine.

It was previously common and sufficient to perform the maintenance with a maintenance team composed of a master and an apprentice. However, with the introduction of new technologies, the master might not be familiar with the new products. This might also justify the new tendency to mainly carry out maintenance with only one operator. In any case, and by applying the guidelines of the ISO guides, the Machinery Directive and Lift Directive give a fairly detailed list of the operations for which the lift manufacturer needs to provide information, including suggested plans for periodic verifications, tests and replacement of any worn components. This is not only to guarantee the necessary level of safety for the whole life of the product, but also to guarantee that the product continues to be fit for the purpose for which it was placed on the market. It is obvious that, if a lack of information on how to keep the lift running properly is suddenly causing it to be out of service, some inappropriate efforts to bring the lift back into service might create hazards. This is why Lift Directive Annex 1 specifies very clearly, “Point 1.1.2 of the Machinery Directive Annex 1 shall be applied in any case!” Major items in this point that directly apply to lifts are underlined in the following:

“1.1.2. PRINCIPLES OF SAFETY INTEGRATION

“(a) Machinery must be designed and constructed so that it is fitted for its function, and can be operated, adjusted and maintained without putting persons at risk when these operations are carried out under the conditions foreseen but also taking into account any reasonably foreseeable misuse thereof. The aim of measures taken must be to eliminate any risk throughout the foreseeable lifetime of the machinery including the phases of transport, assembly, dismantling, disabling and scrapping.

“(b) In selecting the most appropriate methods, the manufacturer or his authorised representative must apply the following principles, in the order given:

- eliminate or reduce risks as far as possible (inherently safe machinery design and construction),

- take the necessary protective measures in relation to risks that cannot be eliminated,

- inform users of the residual risks due to any shortcomings of the protective measures adopted, indicate whether any particular training is required and specify any need to provide personal protective equipment.

“(c) When designing and constructing machinery and when drafting the instructions, the manufacturer or his authorised representative must envisage not only the intended use of the machinery but also any reasonably foreseeable misuse thereof.

“The machinery must be designed and constructed in such a way as to prevent abnormal use if such use would engender a risk. Where appropriate, the instructions must draw the user’s attention to ways — which experience has shown might occur — in which the machinery should not be used.

“(d) Machinery must be designed and constructed to take account of the constraints to which the operator is subject as a result of the necessary or foreseeable use of personal protective equipment.

“(e) Machinery must be supplied with all the special equipment and accessories essential to enable it to be adjusted, maintained and used safely.”

Comparison of the EHSR of Lift & Machinery Directives and the GESR of ISO TS 22559-1

Most Lift Directive items dealing with the instructions for the owner or linked with Machinery Directive Annex 1 Point 1.1.2 are major parts of the practical differences that emerged when comparing the EHSR of the Directives with the GESR of ISO TS 22559-1. The comparison on these points, carried out in ISO TS 22559-1 and included in its Annex C, clearly highlights that this document does not list any GESRs to cover those hazards, as clearly shown Tables 1 and 2, in which the important differences are shown in italics and underlined.

While, in the Lift Directive, these indications have EHSR status, in the ISO TS 22559–1, they are not considered Safety Requirements at all (which would need to be specifically implemented to guarantee the safe operation of the lift and its fitness after its use, practically until its end of life). It is very strange not to dedicate one (or more) specific GESR(s) to inform the user of the ISO document that there would be major risks if adequate instructions were not provided, not only to ensure the correct operation of the safety components, but also to ensure the correct operation of all devices that help keep the lift fit for its purpose. The ISO lift experts likely overlooked the fact that, when introducing innovative solutions, it is not sufficient to specify that the aftersales lift service operators need to be competent, because being competent does not include the capability of guessing which new features or solutions are going to be placed in the market.

This lack of information on how to deal with the new features does not highlight any lack of competence by the lift service operator. Instead, it shows the incorrect behavior by the installer of the lift who does not fulfill his duty to share all the specific information of the new product with the owner. We must understand that we are facing a potentially hazardous situation whenever this procedure is not performed properly, according to the principles of safety integration, with the appropriate set of information handed over to the customer at the end of the installation. This also includes all relevant documents and applicable special tools for the safe execution of all the operations on the lift. In simple words, if the installer of the lift does not complete the supply of his product in this way, the installer might be held responsible for not providing the information and tools necessary to eliminate the hazards caused by the lack of such critical information or tools.

These concepts need to be fully included in any prescriptive safety standard. At the time of this writing, there is still a debate on how to amend the latest version of EN 81–20:2015 to highlight, with clear and detailed requirements, which tools and type(s) of information are mandatory to be included with the maintenance manual handed to the lift owner. This is necessary to really make EN 81– 20:2015 a document that presumes conformity to the EHSRs of the Lift Directive, according to the requirements by the last mandate M/549 to European Committee for Standardization (CEN) by the EU Commission.

In the meantime, some national standardization organizations (NSOs) and other international organizations are planning an action to bring the GESR of ISO TS 8100–20, the new release of the former ISO TS 22559–1, in line with the principles of safety integration, analyzing the hazards caused by the lack of necessary information and tools by risk assessment (as done for all other GESRs). In addition, this work should also verify if there is also a lack of focus on the requirements, at least in the text of the document, to make sure the design of any lift product considers, first, all possible options to provide an “inherently safe design” solution before starting to include additional protections, which are, by definition, a less-safe alternative to the “inherently safe design” ones.

This might be the best option for the document ISO TS 8100-20 to be eventually considered as a global relevance standard: ISO 8100–20: Global Essential Safety Requirements for Lifts, the cornerstone for the implementation of “Global Barrier-free Trade” for lifts.

Conclusions

The rapid increase in the volume of new lifts that implement new solutions, different from those usually present in older ones, could cause an increase in hazardous situations if the instructions, necessary to manage the new solutions and reduce the relevant risks, are not readily available for the operators of the aftersales lift service, which seems to happen often nowadays. Unfortunately, there are many “deviations from the standard,” which are not real innovations improving the product. Rather, they are only one way to introduce some unusual solution creating unexpected difficulties for third parties that might intend to take over the aftersales maintenance service. Indeed, this sort of deviation from the standard would not be necessary and have minor impact on the fair competition for retaining the maintenance service, if the lift owner will receive all the necessary documents and tools from the installer.

If the “principles of safety integration” are properly included in all the lift prescriptive standards, in the mandatory technical regulations and in the new version of ISO 8100–20, there will be many fewer chances of unexpected hazardous situations caused by a lack of appropriate instructions for the maintenance and repairs of lifts, situations in which the service operator might be urged to try all possible, sometimes even improbable, ways to keep a lift operating according to the owner’s expectations. Unfortunately, experience shows that sometimes those ways might be so inappropriate that they could lead to unexpected risks that could be avoided.

All the relevant information concerning maintenance, repairs, periodic verifications and checks could be provided on the manufacturer’s website, in addition to the typical paper copy. This could be the revolutionary solution to the current problem that this set of information does not remain available at the lift site. The idea that the lift installer could open access to the whole set of documentation, with access permitted only to the operators authorized by the owner and provided with the correct access codes, would be a solid guarantee that the necessary information could be available to the service operator anytime. It would allow correct and safe maintenance and/or repair of almost all new lifts operating in the world, thus minimizing the impact of unforeseen risks caused by the rapid implementation of the ever-new technological solutions.

- Table-1

- Table-2

References

[1] Dolores Monet. “Baltimore’s Great Fire of 1904 and Its Legacy

[2] American National Standards Institute. “Through History With Standards”

[3] European Machinery Directive 2006/42/EC

[4] European Lift Directive 2014/33/EU

[5] ISO/TR 11071-1: Comparison of Worldwide Lift Safety Standards – Part 1:

Electric Lifts

[6] ISO/TR 11071-2 Comparison of Worldwide Lift Safety Standards – Part 1:

Hydraulic Lifts

[7] ISO TS 22559-1 Lifts for the Transport of Persons and Goods – Part 1: Global Essential Safety Requirements (GESRs)

[8] EN 81-50:2015: Safety Rules for the Construction and Installation of Lifts — Lifts for the Transport of Persons and Goods — Part 20: Passenger and Goods Passenger Lifts

Get more of Elevator World. Sign up for our free e-newsletter.