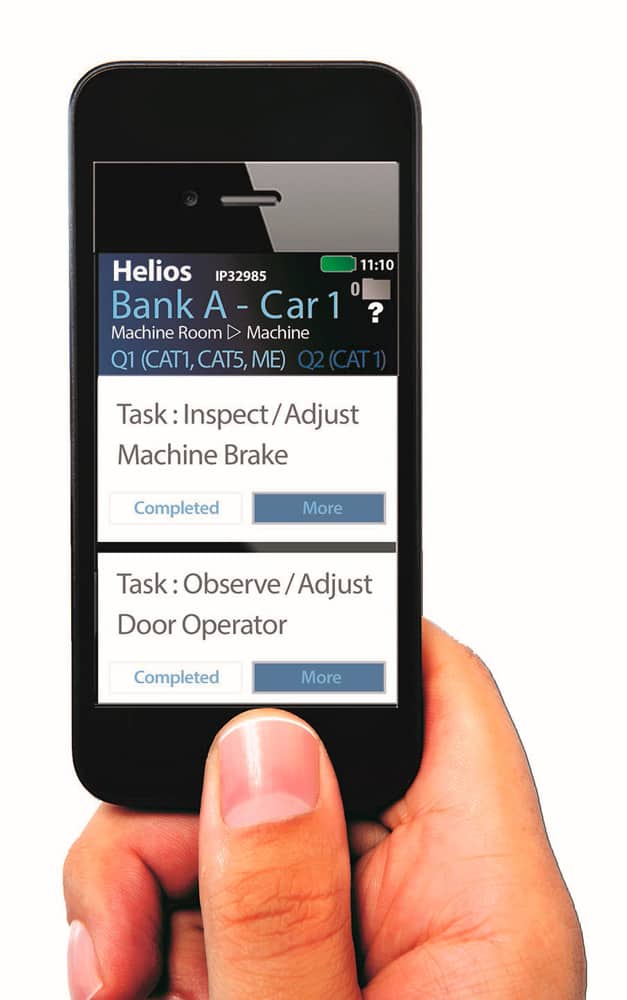

In this Readers Platform, your author describes how GAL and Helios joined forces to create a mobile solution to facilitate the MCP process.

Walking through the National Association of Elevator Contractors (NAEC) convention or having any conversation about the hot topics in the industry often leads to a conversation about the maintenance control program (MCP) and how the industry is handling it. Code changes in the works promise to change the landscape of the MCP and bring recordkeeping to the forefront. Owners, manufacturers and maintenance companies are being asked to ensure correct procedures are defined, performed and maintained. What impact will these changes have, and how will all of us in the industry be affected?

In a new initiative, GAL Manufacturing Corp. set out to take the lead in managing the MCP by storing relevant records on its new GALaxy IV controller, making them accessible to anyone in the machine room from the controller screen. To help complete the task, GAL looked to Helios Enterprise Solutions, a technology company already in the market.

In selecting a partner for this initiative, synergy between parties was key. Helios already had a framework in place that included a mobile device, as well as web- and desktop-based operations. The solution would be designed to create, schedule, perform and track field events including inspections, safety audits, sales surveys and maintenance evaluations.

Partnering with Helios allowed the incorporation of a link from Helios’ mobile application directly to the GALaxy IV controller to leave a copy of the results data directly on the controller for each bank of cars. The solution incorporating the Helios MCP into the GALaxy IV controller debuted at the NAEC convention in Boston in September 2015 and was very well received.

Creating a Unique and Compliant MCP

Helios products are designed as a framework, a platform of functionality that is a blank slate for the requirements of the task it is performing – whether that is the amount of time allotted to complete something, the form it takes or, more importantly, the field tasks performed. Partnering with publishers, content providers and industry professionals, Helios can provide variations on field programs it created, or a unique one can be built. The system is designed to automatically adjust to the data points loaded into the system.

Applying These Principles to the MCP

The MCP is defined by code, but the actual tasks performed and their frequency are based on unique pieces of equipment. For this, it is important to maintain as much information about the unit as possible and define the potential MCP steps based on unique parts and equipment details. Maintaining a master encyclopedia of maintenance-control tasks that will automatically be queried by your portfolio will help define the overall MCP, task frequencies and the steps to complete the tasks. This allows for the creation of a unique program for each unit that can be maintained and tracked for analysis over time. In the case of the Helios solution, the tasks can be maintained against each device, sent to a mobile device for completion and analyzed in the office for open items, discrepancies and modifications based on new requirements.

Taking the Guesswork out of Performing an MCP

Typically, maintenance performance is based on a generic maintenance log stored in the motor room and reliant on a trained mechanic’s skill set. In some cases, there is a working knowledge of ongoing issues which leads to addressing key stress points. Most often, however, it is up to the expertise and knowledge of the mechanic to ensure the right actions are taken to perform the MCP. The proper mobile solution takes the guesswork out of this potentially volatile process. No longer does a mechanic have to rely on limited data, as the required actions and processes are now accessible on a mobile device, which is essentially a digital toolbox.

Giving Mechanics and Managers the Mobile Advantage

With a proper MCP defined for each unit in a building and the frequencies correctly applied, the needs and requirements are transparent, and the process adds value to the mechanic’s expertise and ability to spot additional issues on the scene. Tracking the actions through a mobile device allows for not only the ability to see which tasks were completed, but also which actions were taken and the follow up required (sales leads, repair teams, parts, etc.). The MCP is now a living, breathing document that helps create a more efficient and accurate operational back office. For instance, open items and typical pain points for a site or type of unit are identified. The Helios solution also allows for the inclusion of photos directly into the MCP to enhance recordkeeping.

Ending Efficiency Nightmares

Until recently, operational management has been a paper nightmare, relying on time tickets and spreadsheets to ensure the MCP was performed and hoping open items were relayed to the supervisor for followup. In addition to leaving a copy of the completed MCP tasks on a GALaxy controller, the Helios solution will transmit the results for any type of unit back to the office to show the requirement was completed, as well as any open items defined by the field user. In one seamless automated process, the operations group can ensure all of the requirements are met, as well as track any open items without having to look at one piece of paper or follow up with any mechanic. This increases turnaround, providing more time to address sales leads, order parts and schedule repairs, while ensuring none of these items go unaccounted.

Creating a Safer and Better MCP

Identifying how to keep the riding public and people who work on equipment safe is paramount, no matter the logo on your shirt. To this end, Helios is looking to be the CARFAX® for all equipment. This will help ensure transparency throughout changes in elevator companies, consultants and even owners, and create a safer elevator for everyone.

In addition, institutions and organizations can create master MCP databases for all to draw from. Pooling resources to ensure the correct steps are followed and key issues are identified will create a more uniform approach to safety throughout the industry. GAL believes its partnership with Helios has achieved the goal of a safer and more compliant environment by thoroughly and efficiently managing the MCP process from inception to closeout.

GAL GALaxy IV Elevator Control and Helios Remote Application

by Doug Witham, vice president, Sales and Marketing, GAL Manufacturing Corp.

As a subset of what Helios has done with its remote application, GAL and Helios have combined to take the MCP process to the next level. An elevator contractor can have a completely customized MCP, including tasks and frequencies defined for each piece of equipment. A technician can then go onto the job, call up the specific equipment on a smartphone or tablet, see any/all of the MCP tasks due to be performed and record the status of each. When completed, the technician presses a “sync” button, and instantly, the MCP data is stored on the control, as well as emailed to the office with no paperwork involved.

The technician can classify each task in any number of ways to include a picture, request a team, or report a problem or sales opportunity. All of this information is also sent back to the office, as well as satisfying the code requirements for MCP data required to remain available to elevator personnel onsite. The key to this ability is that GAL’s GALaxy IV md (maintenance documentation) elevator control has its own server and creates its own wireless (Wi-Fi) hot spot. The technician can hook up with the GALaxy IV control via Wi-Fi and communicate with it.

Get more of Elevator World. Sign up for our free e-newsletter.