An EW-moderated discussion among chief elevator inspectors regarding significant proposed changes to ASME A17 code

The following is an e-mail conversation held between ELEVATOR WORLD and a number of chief elevator inspectors in relation to significant ASME A17 code changes proposed by the vertical-transportation industry for final acceptance and periodic testing of elevators and escalators. As we all know, change is inevitable and, often, for the better. However, for those in our industry charged with the responsibility of ensuring public safety, the benefits of the proposed change are difficult to assess. The participants in this conversation consisted of EW and the following chief elevator inspectors: John Antona, City of Miami Beach; Michael Chavez, Miami-Dade County; Lawrence Taylor, Texas; and Jack Day, Washington. We hope this conversation will give readers an appreciation for what these industry professionals go through on a daily basis and what they do on behalf of the elevator- and escalator-riding public.

The subjects discussed are based on a number of proposed revisions to ASME A17.1 Safety Code for Elevators, Escalators and Moving Walks. We encourage readers to send us their opinions on this topic relative to how the elevator industry has addressed public safety for nearly 100 years, versus how it will likely be approached in the future. We also encourage readers who may initially take exception to many of the early comments made during this discussion to stay with it to the end where, I assure you, “cooler heads prevail.”

EW: Let’s begin by discussing what each of you thinks about the proposed A17 code revisions relative to allowing elevator companies to use alternative testing procedures in lieu of traditional safety tests.

Lawrence Taylor (LT): Regarding the most recent industry proposal for us (AHJs) to accept alternative testing methods, I believe this hasn’t been well thought out and is based on the simple premise that others in the world do it this way and so should we. I would suggest that the uniquely American way of doing things is working fine. I see no clear evidence to indicate that the current procedures we are using are creating problems. Additionally, the skill sets needed by mechanics to perform these new complicated tests don’t currently exist in the workforce, making the reliability of the results that we will get questionable. Many of the field people I encounter are still unclear on how to properly perform the step/skirt index test. Expecting them to learn how to properly perform these complicated alternative tests is an unrealistic expectation that makes me uncomfortable – especially in regards to the safety of our constituents. These important tests aren’t something people should be learning on the job.

EW: In numerous presentations I have seen on this subject, it has been said that the proposed test procedures are based on sound engineering results and testing performed throughout the world, as well as in some areas of North America. It has also been emphasized that the purpose of allowing the alternative tests is not based on problems with the current testing methods, but instead on the fact that performing tests without test weights reduces potential injury to personnel, transportation costs and fuel consumption. The industry also states that the systems used to perform the alternative tests are not complicated to use.

LT: I must respectfully reaffirm my dissenting position on this matter. The argument in support of the industry’s proposal is lacking and does very little to address or improve safety. This in itself convinces me there is something amiss in their rationale and that these alternative tests are ill-conceived at best. Although I do understand their position, I will not remove my negative vote. The idea of finding an easier, simpler means of testing is very appealing to me, but my enthusiasm for this is tempered by my sworn duty to ensure the safety of citizens and visitors to the State of Texas.

EW: All these proposed code changes and the state of technical revision balloting on them are posted on the ASME Codes & Standards Connect website (www.cstools.asme.org), so AHJs should be able to review all of the proposals.

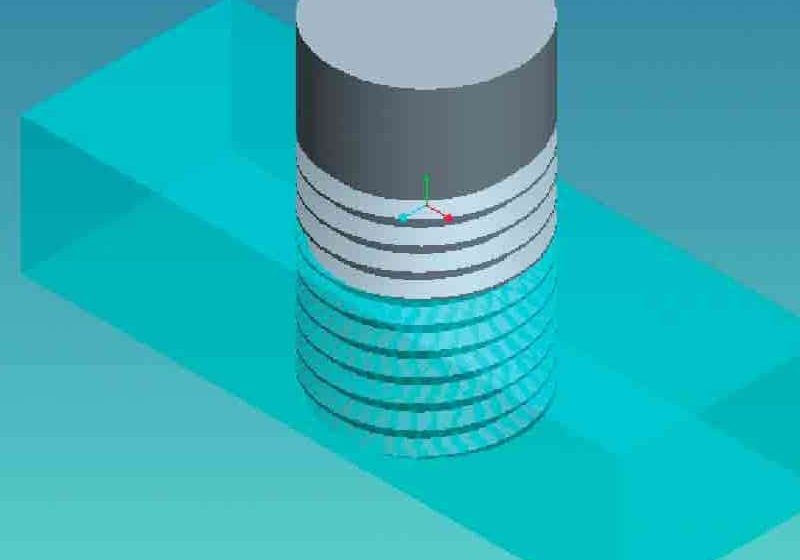

Michael Chavez (MC): I was unable to thread through to the ASME C&S site, but from the e-mails I read on the subject, I take it that this is about the newly proposed method of testing safety devices using engineering calculations only and not implementing a physical test. This is also aligned with the proposed method of performing remote safety tests, using computer-based systems to engage various safety systems at remote locations and reading the results remotely, while the licensed inspector witnesses the test from a computer screen.

I have been in this business for almost 40 years, from the OEM side, owner representative side and regulatory side, and I have seen it all. The “proof is in the pudding,” as they say. For years in my jurisdiction, AHJs performed inspections and witnessed tests on new installations, but did not witness periodic testing on existing units performed by all maintenance providers. That was until 2000, when it became required under code for all periodic tests to be witnessed by an inspector. When this began, we saw many units get torn up because their safety components were inoperable. Units crashed into overheads and other things, all as a result of previous testing under the honor system. This happened for all companies – majors and independents alike. Too much can happen to a piece of equipment in use in the real world.

We also have the problem of technicians who are improperly trained and equipped, and are under the gun by their managers and companies to perform tasks without sufficient time to accomplish them. We end up with required maintenance performed improperly, if at all, and this is being reported through the companies’ computer systems. I call this “virtual maintenance.” Now, we want to virtually test the equipment being virtually maintained. That’s a good one, folks!

Jack Day (JD): Your sentiments are right on target. The only way to change this will be to challenge it. To challenge, we must get involved. I believe only AHJs and inspectors, through standardized enforcement, have a chance to change the attributes associated with maintenance today. Here is a chance to change the face of maintenance in the U.S.

LT: I’m glad to hear that I’m not alone on this issue. Based on what I see when I get out into the field, I do not have a great deal of confidence in the commitment of those clamoring for these alternative methods to provide the means, training, and support needed by the field people. Those pushing these alternatives should ensure the field people can effectively perform these tests and that they understand how/when to question the validity of the results in verifying safety.

EW: The alternative test concept is not quite as you described. On acceptance of equipment, full-load tests will be performed to establish a baseline of the test results, which will be recorded by and stored in computer software for future reference and comparison of future periodic no-load safety test results. What are some of your specific concerns with what is being proposed?

MC: It’s not that I don’t trust the elevator companies, but they aren’t perfect, and we are dealing with people’s lives. I say “no” to virtual and remote testing. I have accepted computer reporting and the “available” maintenance control programs from some of the elevator companies, but I haven’t liked them. From what I’ve seen, I don’t trust it, and, to put it kindly, people make mistakes.

LT: I agree. My responsibility is to protect the citizens of my state, and I see this proposal for alternative and/or remote testing as a cleverly designed scheme to make it difficult, if not impossible, for me to fulfill that responsibility. To quote Ronald Reagan, “Trust but Verify.” When I see the difficulties we regulatory agencies have getting compliance with the code now, I am worried that the current proposals will have a negative impact on public safety.

EW: It appears that the alternative tests will be less burdensome on mechanics, as well as inspectors, and the elimination of test weights in periodic tests could prevent injury to those performing the assessments.

LT: I was not aware that ASME had authority over occupational safety, energy conservation, or the use of natural resources. I see what I believe to be a disturbing trend – some of the industry representatives on the code committees using the process to minimize their employer’s liability and the power of “the code” to coerce building owners (instead of industry) to foot the bill for employee safety. The rationale that “An equivalent result without the use of test weights reduces the potential for injury to personnel, transportation, and fuel consumption” is beyond the scope of A17 and is, in my humble opinion, nothing more than a ploy to usurp the power of the AHJ. One only needs to look no further than the Maintenance Control Program fiasco to see the fallacy and illogic in the current proposal.

EW: It does not appear that any of you buy this argument or support the proposals being put forth.

John Antona (JA): This could be the equivalent of a Wall Street protest in the elevator industry.

EW: I’m afraid it might be worse, as you are all expressing strong opposition to the proposed industry practices you feel will compromise public safety. I knew how some of you felt about this issue, and I now see that others are also very much against the alternative testing proposal.

You are all chief elevator inspectors. There is strength in numbers; however, the number opposed to these proposals willing and able to vote against them might not be high enough to defeat them. In view of this, it appears that those opposing the proposals will likely be significantly outvoted on the ballots. As you are charged with looking after public safety, it seems that your votes should carry more weight on the A17 committees than they do. Which leads to my next question: do you feel that the QEI certifying organizations and other inspectors who are members of the Regulatory Advisory Council will support your views on this subject?

LT: I don’t believe the QEI accredited agencies are in a position to have much, if any, impact on the outcome one way or the other. The problem as I see it is the industry writing the rules and then using their influence to see them passed and made part of a published document. The potential for impropriety and appearance of a conflict of interest is overwhelmingly apparent to even the most casual observer. It is my opinion that manufacturers, contractors and their hired professional code writers should recuse themselves from voting on these proposals.

JA: You have all made some very good points. My opinion is that it is too early to react to the quick responses of a few inspectors or AHJ representatives. ASME develops codes under procedures accredited as meeting the criteria for the American National Standards Institute. Participation by the AHJ is nothing new and has been encouraged by ASME in the past, particularly through the Regulatory Advisory Council and/or encouraging contributions of corresponding members for any committee. Is it due to lack of time or interest that AHJ participation is so low?

No one has mentioned the A17.7 performance-based code (PBC), and that’s what they should really worry about. AHJs will no longer be needed for new installations if the A17.7 PBC is implemented to the extent it has been in Europe. The “elevator revolution” may have started, but it is not yet ready to resist the looming slaughter.

EW: What do you feel the future has in store for us?

LT: Change is inevitable and generally can be a good thing. However, “good change” must have a positive impact and benefit the public. What I’m having trouble seeing in these alternative testing proposals is the benefit to the public. I don’t recall seeing any rationale that shows how public safety will be enhanced by these proposals. The primary basis as I see it seems to be saving fuel and reducing travel time and injury to the industry employees. This seems contrary to the stated purpose of the code to promote the public welfare. I honestly believe there are ways to improve public safety with the use of technology and new ways of doing things; I just don’t see that in these proposals.

JA: Times are changing, and we must look to the future, not the present or the past. Our current system is outdated and overburdened by too many rules and regulations – inspections, annual tests, five-year tests, records, restrictions, etc. Change will be inevitable. The entire construction industry is slowly changing, and we must look at the global picture. With a PBC, I predict that in the not-so-distant future, AHJs will only keep a record of units for licensing and accident reporting – just like you do with your personal automobile.

My latest paper will compare PBC against prescriptive code (PC) approaches and emphasize the differences. While I believe PCs are safer, I understand PBCs are more flexible, less restrictive and customer friendly. As for the safety of the riding public, I suggest you ask yourself the following: “Has your automobile become less safe since annual inspection requirements ceased in your area of the country?” My answer to this is “no,” because they are making better cars today. Let’s hope our industry moves in that direction as well.

EW: We encourage others in the industry to weigh in on these important issues as well. Readers can do so by sending a letter or email to the editor at bob@elevator world.com or by continuing this discussion on the EW online forum as directed below.

Get more of Elevator World. Sign up for our free e-newsletter.