Actual Rope Research and Products for Elevator Applications

Sep 1, 2013

Pfeifer DRAKO Drahtseilwerk GmbH, Germany

This paper was presented at  USA 2012, the International Congress on Vertical Transportation Technologies, and first published in IAEE book Elevator Technology 19, edited by A. Lustig. It is a reprint with permission from the International Association of Elevator Engineers

USA 2012, the International Congress on Vertical Transportation Technologies, and first published in IAEE book Elevator Technology 19, edited by A. Lustig. It is a reprint with permission from the International Association of Elevator Engineers  (website: www.elevcon.com). This paper is an exact reprint and has not been edited by ELEVATOR WORLD.

(website: www.elevcon.com). This paper is an exact reprint and has not been edited by ELEVATOR WORLD.

Key Words: Steel wire ropes, small rope, lifetime, certification, calculation, plastic cover

Abstract

Steel wire ropes have an interface function in the system traction elevator. The ropes influence the dimensioning of the rope drive as well as other themes as costs, energy efficiency, used shaft space, production, installation and maintenance. Smaller rope diameter will decrease the diameter of the traction and the diverter pulleys. The use of steel wire ropes with a diameter d below 8mm and a ratio of diameter pulley to rope D/d below 40 will open new possiblities in elevator system construction. Steel wire ropes covered by materials with higher friction coefficient will allow to reduce wrapping angle of the traction pulley and avoid the sharp traction grooves. Flat and slim terminations for steel wire ropes have the advantage in increase liftetime avoiding incline angles on the pulleys. Additional the method for calculation of the expected number of trips has to be improved especially for complex rope courses in the elevator system. Certificates issued by Notified Bodies are necessary to show the suitability of new products in elevators. The influence of new rope products and methods and their linking-up will be presented.

1. Small Ropes – Small Sheaves

The development of smaller rope drives in traction lifts is not yet finished. First steps were the decrease of rope diameter below 8mm as required in EN81-1. With a constant ratio of diameter of the sheave to the diameter of the rope D/d the sheave diameter decreased enormous. With the additional measure decreasing the D/d-ratio below 40 – e.g. in the examination certificate KP067-1 – a ratio D/d=25 and a sheave diameter of D=150mm with the DRAKO 250T in 6mm is possible. An allowed D/d=24,6 reduces the sheave diameter to D=160mm for the 6,5mm-rope in the same construction.

The certificate KP067-1 is basing on liftetime bending tests until discard, statistics and an approved lifetime calculation (Fey2022) covered by the traditional calculation of the traction capacity for V-grooves and semicular grooves with undercut. The results are decision graphs (Figure 1) for the calculated and expected number of trips. The bending sequence is one bending over the traction pulley and two bendings over the deflection pulleys. Now the lift manufacturer decides after the traction capacity calculation the parameters D/d-ratio of traction and deflection pulleys and the safety factor. The calculated number of trips in the decision graphs of the KP067-1 mirrored with the expected travel frequency will lead to the time of usage until rope discard. The decision graphs are valid for steel and plastic deflection pulleys in traction and hydraulic lifts.

2. Lifetime Calculation Influenced By Reverse Bendings

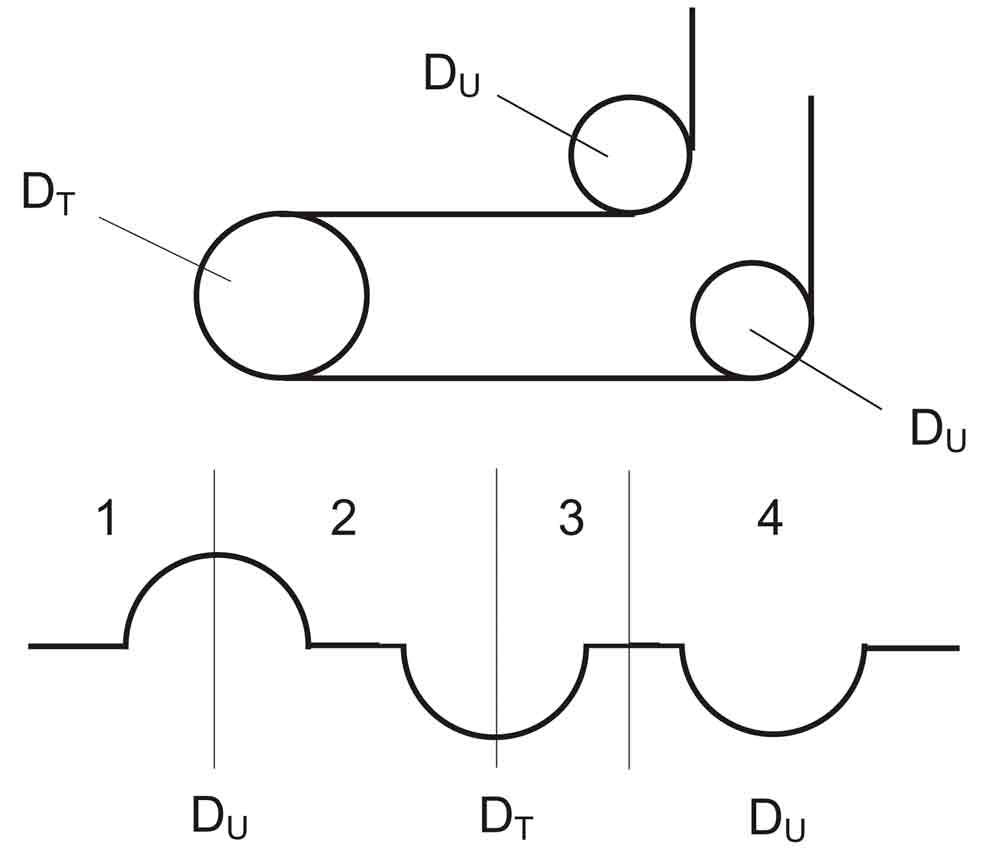

The rope lifetime calculations used for the DRAKO-certificate KP067-1 respected only bendings in the same direction. The case of reverse bendings (Figure 2) is used very often underestimating the influence on rope lifetime. In Vog2010 a method was described to cumulate all influences of the reverse bendings and the traction sheaves by splitting the bending sequence in single bending cycle elements. A calculation of the service life must take account of the bending sequence in the rope section subjected to the greatest level of stress. Once the bending sequence and bending elements are known, it is possible to attribute the influences of reverse bending and of the shaped groove. A number of bending cycles must be calculated for each bending element and collated to the number of trips usind the damage accumulation hypothesis put forward by Palmgren-Miner. Attention must be paid when using this bending element model not to under or over represent the influence of either reverse bending or shaped groove, both of which exert an extreme impact on rope life. Further certification works will also cover this type of bendings.

Figure 2. Reverse bending

3. Plastic Covered Rope

The certificate KP067-1 covers the steel wire rope D250T in 6, 6.5 and 8mm for D/d≥24,6 and in principal open safety factors. But: Don´t forget the influence on rope lifetime. Use the decision graphs to get an idea what can be expected. The KP067-1 handles with steel wire ropes with limited friction coefficient of steel-steel combination. To increase the friction a plastic cover is helpful. The advantages are long lifetime caused by reduced pressure, use of round grooves, silent run and reduced wrapping angle. The plastic covered rope PTX300 is certificated in G530 with detailed instructions and discard criteria.

4. Rope Termination T-Socket

VogScheu2011 presented a patented termination which allows an installation of the ropes – important especially for small ropes – without incline angles. The lifetime is not disturbed by additional stresses and rope movements. Additional measures as screws and springs help to equalize rope forces.

5. Conclusion

The steel wire rope is a very interesting construction element in the fantastic machine traction lift covering installation, maintainance, safety requirements, traction capacity, comfort aspects,…. It´s never boring and needs a deep understanding what occurs after changing or varying even only one parameter. Certificates based on scientific research will help to use the ropes even in heavy duty treatment in a safe way.

REFERENCES

Vog2010 Vogel, W.: The impact of reverse bendings in the rope drives of traction lifts. LiftReport 36(2010)2, page 14-16

Fey2002 Feyrer, K. (2002). Drahtseile. Springer Verlag Berlin 2002

VogScheu2011 Vogel, W., Scheunemann, W.: Safety and reliability of rope terminations in traction lifts geplant: Lift Report 37(2011)6

KP067-1 Certificate concerning the examination of conformity KP067-1 – Rope drive for use as part of the machine for traction drive lifts resp. indirect acting hydraulic lifts with and without reduced number of

travels Pfeifer DRAKO/TÜV Süd 2011

G530 Type examination certificate for a rope drive for use as part of the drive lifts Type DRAKO PTX300 (dnom=6mm) TÜV Süd 2009

Get more of Elevator World. Sign up for our free e-newsletter.