Pump, drive, traction machine and testing device use some of the latest technologies.

Hydraulic Pump with VVVF Inverter

Bagnatica, Italy-based Omarlift has released its Hi Hydraulic Pump, intended for both new installations and modernizations. Featuring a variable-voltage, variable-frequency (VVVF) inverter, it uses up to 50% less energy than traditional pump units. Other features include:

- Integrated hand pump

- Inverter-managed upward and downward travel

- Open-loop system without encoder

- Speeds up to 1 mps

- Precise floor approach not dependent on the load

- Adjustable inspection and releveling speeds

- Speed controls for intermediate floors

- In conformity with EN 81-2:1998+a3

- Available with pumps with 55-600 l/min. and motors with 3.3-58.8 kW

Onsite Swaging, Testing Machine

Alps Wire Rope Corp. has introduced Petersen Stainless Rigging’s P400, a mobile solution for onsite swaging and testing of wire‐rope terminations and crane cable repairs. The machine allows the correct pressing of swage sockets onto wire rope. After fitting the socket, the rope can be gripped and a proof load applied, all on the same machine. Proof load tests can be carried out on lifting assemblies without the need for external equipment, and assembly can be done onsite.

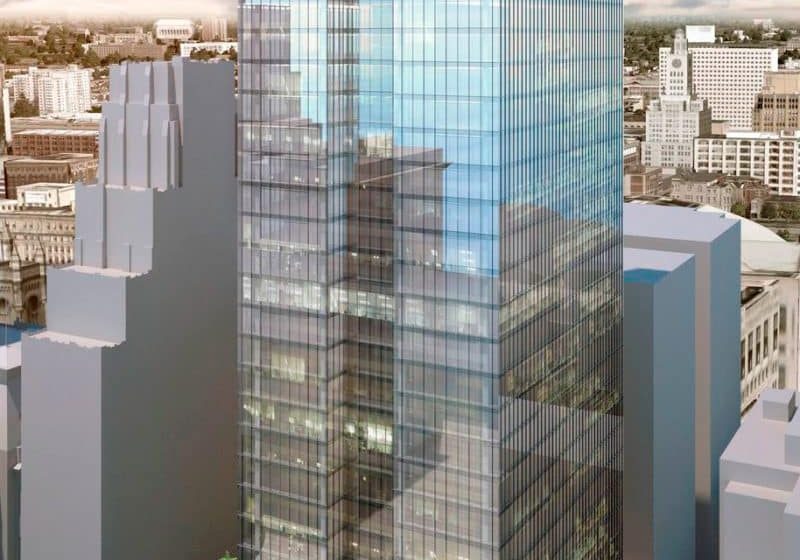

Heavy-Duty Machine

Wittur has launched a new high-rise gearless traction machine, the WSG-52. Marking the top of the German manufacturer’s gearless machine range, the product has a nominal torque of 9,200 Nm and is designed to lift as much as 9,800 kg in a 2:1 roping configuration. Traveling speed is as much as 12 mps in 1:1 applications. Other features are:

- Nodular-graphite cast-iron housing

- Centrally fixed traction sheave

- Allowance of 520-kN shaft load with up to four safety brakes

- Synchronous 20-pole motor with high-efficiency permanent magnets

- Insulation class 155 (F)

- Forced air cooling, low-noise ventilation

- Various electrical options regarding speed, voltage and feedback system

- Electromagnetic dual-circuit safety brakes that are constantly monitored with a secondary switch for wear detection

- Ability to be used for unintended-car-movement solution

- Customized traction groove profile design

Dedicated Lift Drive for Retrofits

The new VLT® Lift Drive LD 302 is described by Danish elevator drive manufacturer Danfoss as “an off-the-shelf solution” that allows the retrofit of just the elevator drive. Intended to keep downtime to the bare minimum, it prevents companies from having to replace the entire lift controller or repair the existing drive. Other features include a smooth, quiet and fast ride, and a specially controlled fan that only runs when needed. Its design as a dedicated lift drive can make it easier to configure than other options.

Attempts to replace obsolete elevator drives with standard inverters customized with option modules to run lift applications can be difficult to install and require more time and effort to transfer parameters and programs due to the closed architecture. The LD 302 is intended to speed installation, as unlike many other variable-speed drives, it boasts an open architecture with a simple menu structure written in plain language using elevator terminology.

Get more of Elevator World. Sign up for our free e-newsletter.