M1 – T4 – M2 Metro Routes Project in the European Side Railway Systems Routes of Istanbul Metropolitan Municipality

by Nazım Keskin

Transportation networks develop every passing day in Türkiye and across the world, while the need for heavy-duty escalators in areas with mass usage such as airports, metro routes and express train projects also increases accordingly.

As AKE, our journey with escalators started in 2006, and we commenced production with our own brand at our factory in 2012. Now, our escalators are used at shopping malls, business centers, airports, metro stations and transportation networks in various cities in Türkiye and abroad.

We, as a domestic company, produce escalators that have become a part of our lives and are needed in our country and the neighboring geography. We also increased our factory’s production capacity with new investments in 2017. Currently, we have a capacity of producing 480 escalators annually and the potential to double our capacity by adding new shifts.

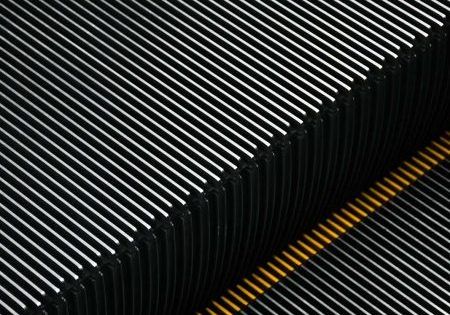

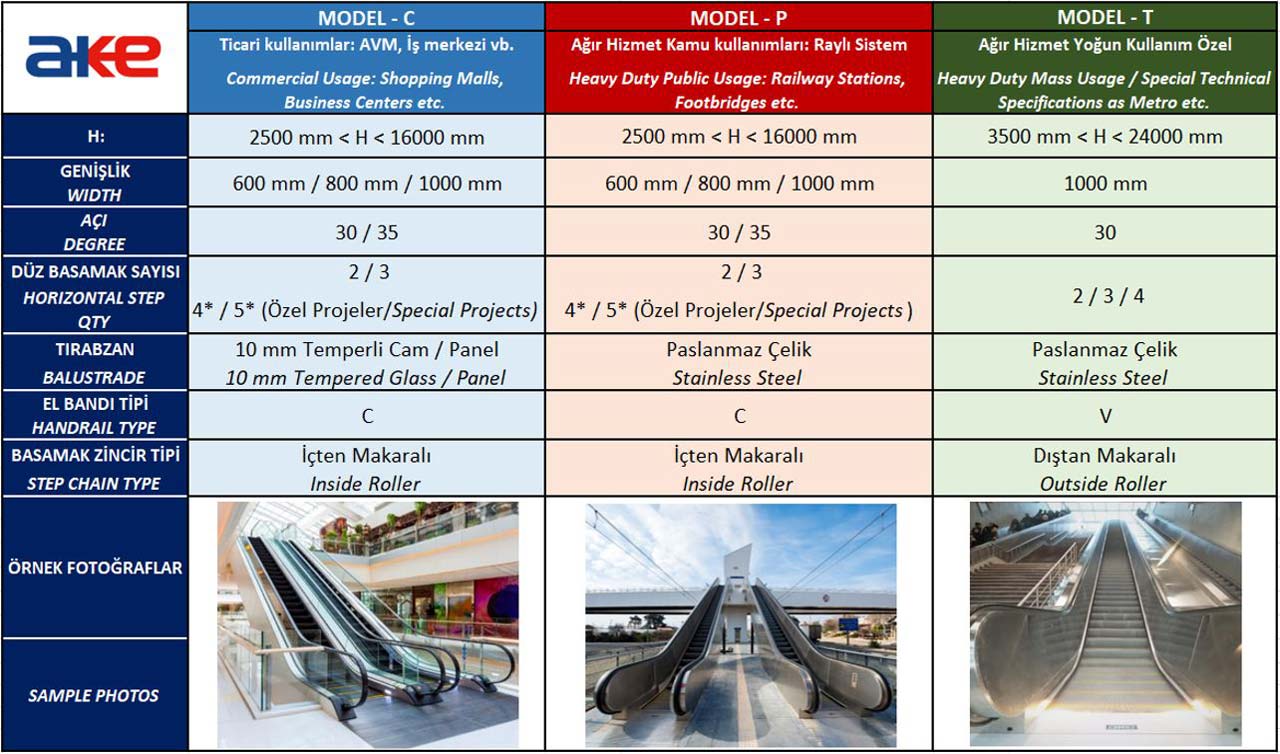

AKE Elevators consist of three main models including Model C (Commercial), Model P (Heavy Duty Public Usage) and Model T (Heavy Duty Metro).

Especially in the projects with heavy human traffic, our product fulfilling the relevant standard and technical specification is Model T.

Model T attracts intensive attention especially in Europe, apart from the transportation network projects in Türkiye.

We performed the first production and installation of the Model T heavy duty escalator by undertaking the construction project of 47 lifts and 15 heavy duty escalators for which the Istanbul Metropolitan Municipality, Department of Railway Stations of the European Side initiated tender in 2017.

Among the units in the project, an escalator with a height of 16 m at M1 Metro Route Bahçelievler Metro Station differed from others in terms of its design.

What are the distinctive features of the project?

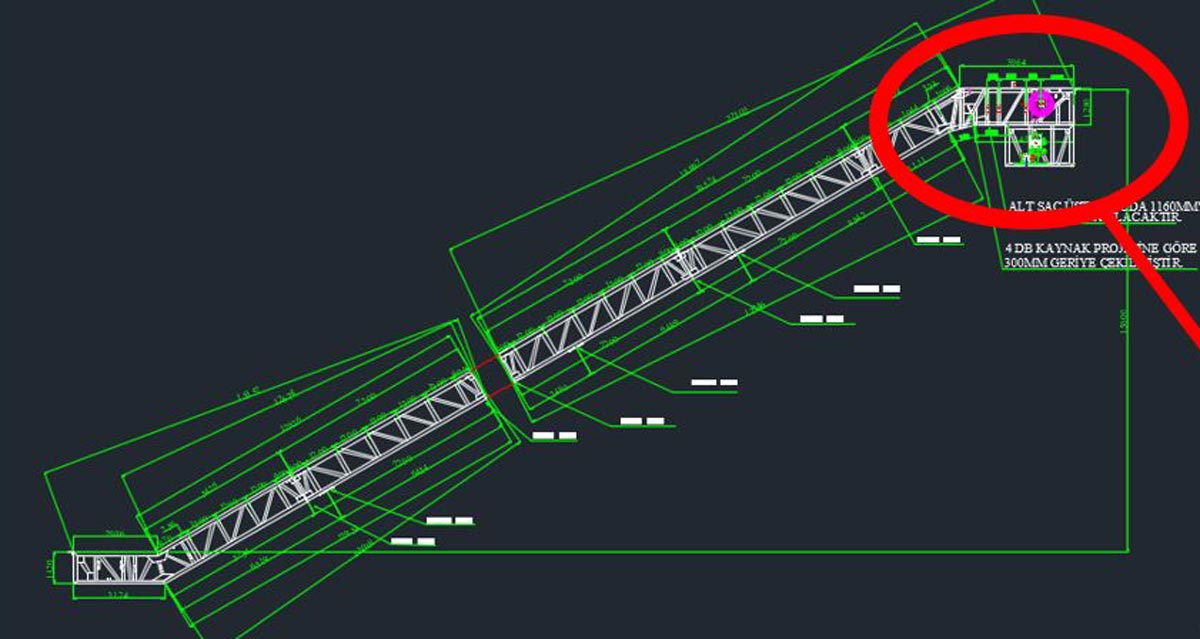

When our new unit, which would be installed next to another escalator produced according to the old standards and technical specifications in the current station, was designed according to the new standards (EN 115-1:2017) and technical specifications, its L height was longer than the old escalator, and it seemed impossible to install the new escalator since it coincided with the full building dilatation.

As a result of the investigations and assessments we conducted together with our R&D department and engineer fellows who are expert in their areas, it was decided that the L height could be shortened by changing the design of the escalator’s upper well adhering to the current standard and technical specifications.

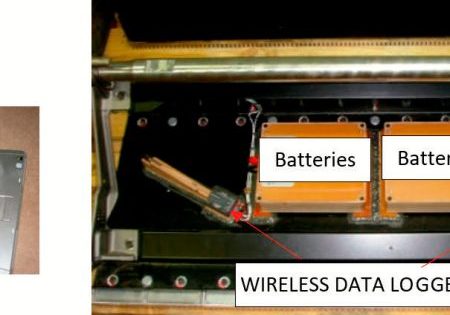

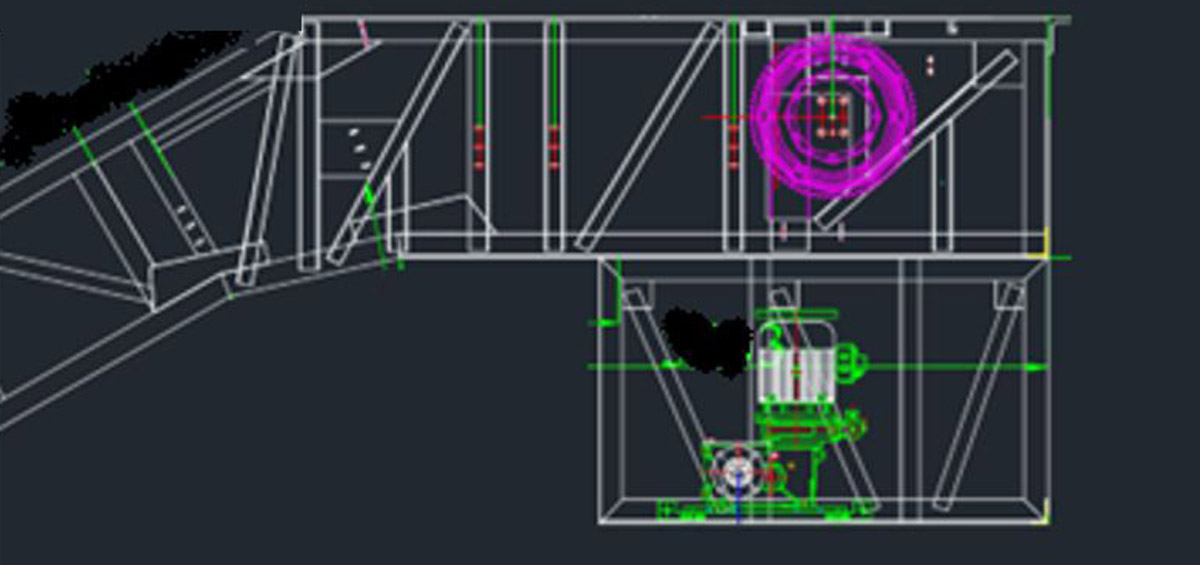

The twin engine in the upper well where the traction group is located was placed under the well so that the engine space was gained and L margin was shortened. The escalator was designed with a vertical drive.

Design studies were initiated in Solidworks platform. During the design studies, the system components were modelled considering the standards below, while the final elements method for statics and dynamics analyses were performed on ANSYS platform.

- TS EN 115-1 “Safety of escalators and moving walks – Part 1: Construction and installation”

- TS EN 115-2 “Rules for the improvement of safety of existing escalators and moving walks”

- APTA RT-EE-RP-001-02 “Heavy-Duty Transportation System Escalator Design Guidelines”

- TS EN ISO 12100:2010 “Safety of machinery – General principles for design – Risk assessment and risk reduction”

- TS EN ISO 12100:2010 “Safety of machinery – Basic concepts, general principles for design – Part 2: Technical principles”

- ISO 18738-2:2012 Measurement of ride qality – Part 2: Escalators and moving walks

- Technical Specifications, 2017 “Construction of Lifts and Escalators in the Railway System in Istanbul”

What was done during the product transportation and installment?

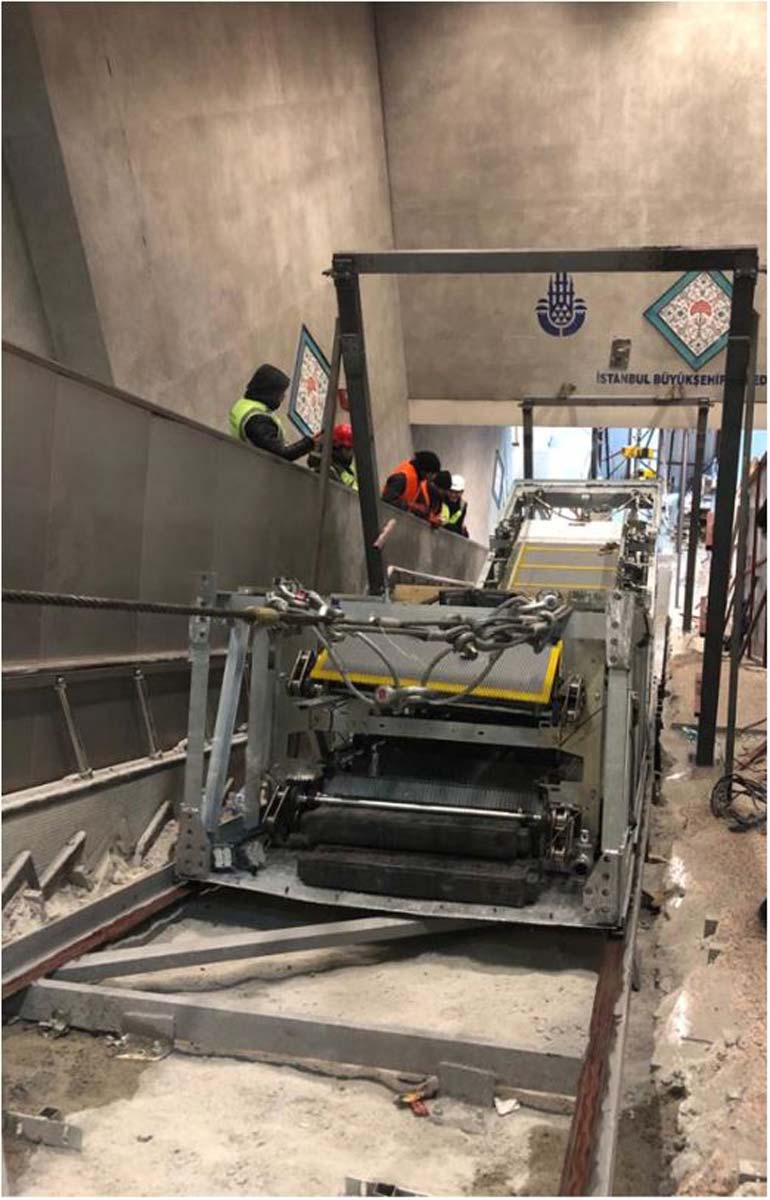

Another challenge of the project was that the installation had to be performed at an existing station in use, and that it had to be completed as defect- and accident-free paying regard to the OHS rules and environmental conditions.

The escalator was decided to be produced in five parts for the convenience of delivery and installment.

The relevant parts were transferred into and installed in the well upon its completed construction by sliding them gradually downwards from top of the well using the steel construction piles we designed in a way to fit directly between the escalator and well. These steel piles also acted as central support for the escalator without a need for an extra support.

The units in the relevant project were delivered stage by stage as of 2018, and the project was entirely completed and delivered in 2019. Technical service was provided from our company as part of the guarantee until 2021, and the maintenance of our units at M2 route were contracted to another company within the scope of the new maintenance tender in 2021. The maintenance of our units at M1-T4 route is still performed by our company.

Get more of Elevator World. Sign up for our free e-newsletter.