An Exploration of Elevator Cloud Solutions

Feb 1, 2025

Digitalization to enhance safety

by Chao Du, Hao Gao and Jian Cao

Introduction

This article describes relevant cloud-computing solutions to enhance elevator safety through digitalization. Elevator core data obtained through the elevator cloud system can automatically generate elevator operation reports and use big data analysis technology to check elevator safety hazards and dynamically score elevator health, thereby improving the level of intelligent emergency rescue. At the same time, such solutions can contribute to healthy and rapid development of on-demand maintenance, elevator insurance and modernization services for older elevators.

Background

As indispensable vertical-transportation equipment in modern buildings, elevators’ safe operation is directly related to the safety of life and property of every passenger. Therefore, ensuring the continuous and stable operation of elevators is crucial to maintaining public safety and improving quality of life. In recent years, the number of existing elevators globally has continued to grow, with more than 20 million elevators in use worldwide.[1] At the same time, the number of old elevators has increased rapidly, and various potential risks and hidden dangers continue to accumulate. However, repair, maintenance and modernization of most elevators are still carried out in the traditional way. Without relying on digital means such as cloud computing, it is difficult to ensure the safe operation of elevators on a large scale. In this article, from the perspective of the elevator Internet of Things (IoT), your authors introduce an elevator cloud solution from the standpoint of system structure and system function to help elevators operate safely.

System Architecture of the Elevator Cloud Solution

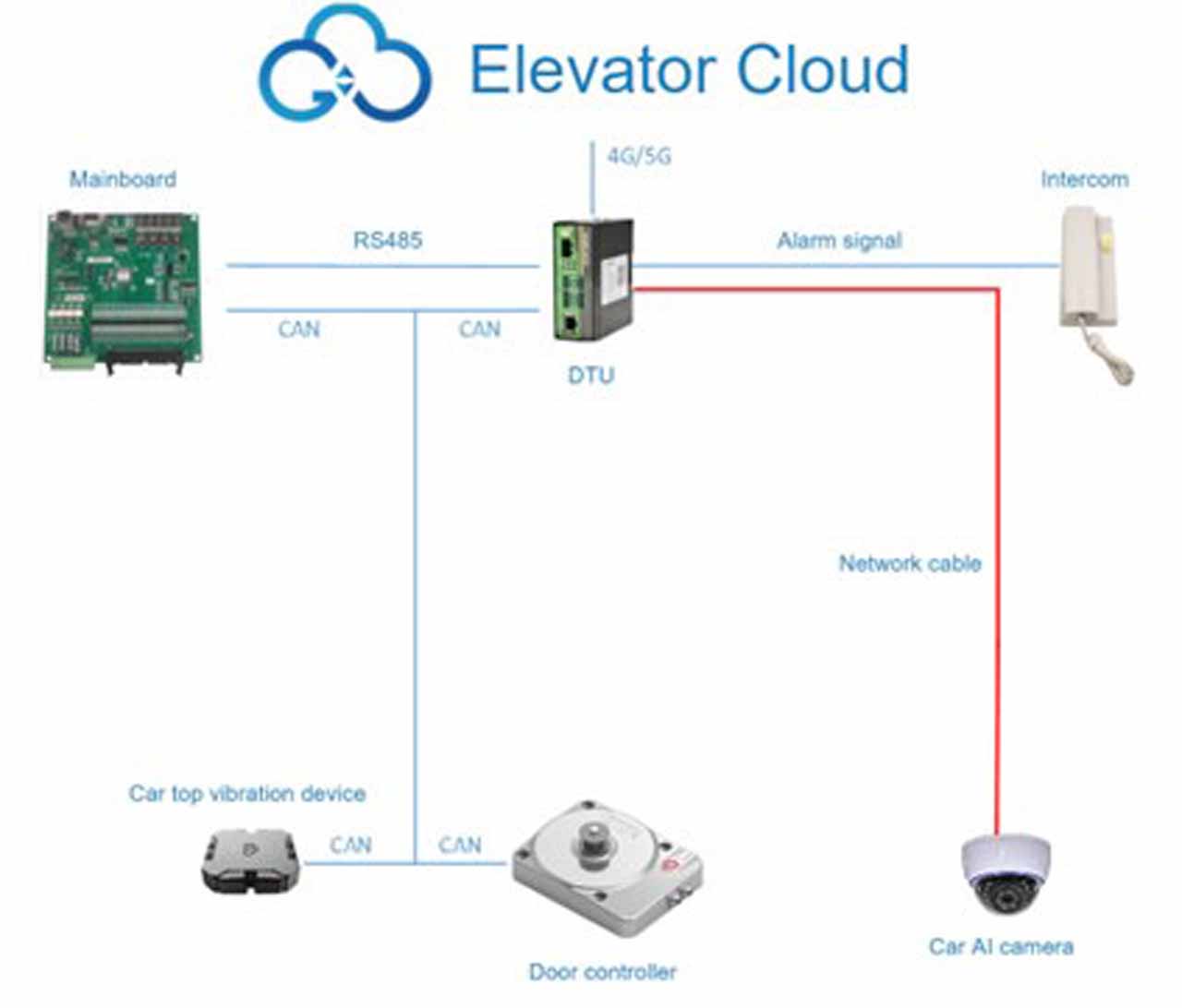

Figure 1 shows a system architecture diagram of the elevator cloud solution. It mainly includes the cloud platform, machine room mainboard, machine room data terminal unit (DTU), car top vibration collection and analysis device, door controller, car AI camera, intercom system, etc. The machine room DTU collects core electrical data of the elevator control system through a serial bus (such as RS485) and converges the vibration data collected by the car top vibration collection and analysis device and the door operation and fault data provided by the door controller through serial buses such as CAN-BUS. It can also collect alarm data from the intercom system. At the same time, the machine room DTU can obtain data based on real-time video showing abnormal passenger behavior provided by the car AI camera through transmission media such as network cables. As a data aggregation and processing unit, the machine room gateway can report relevant data to the cloud platform after edge computing. Then, the cloud platform will perform data analysis and processing to form various functional modules.

Without relying on digital means such as cloud computing, it is difficult to ensure the safe operation of elevators on a large scale.

System Functions of the Elevator Cloud Solution

This system uses elevator cloud technology to achieve automatic troubleshooting. The system:

- Fully utilizes the three major data sources of the control system, door machine system and human-machine system

- Automatically reports the status of core electronic control components through control system signals

- Automatically identifies improper elevator riding behavior through AI cameras

- Automatically identifies abnormal vibration events involving mechanical components through vibration collection and analysis devices

Elevator Operation Report Automatic Generation Technology

Through technologies such as elevator IoT, big data analysis and cloud computing, report data can be automatically collected and stored, in turn automatically producing periodic elevator operation reports daily, weekly and monthly.

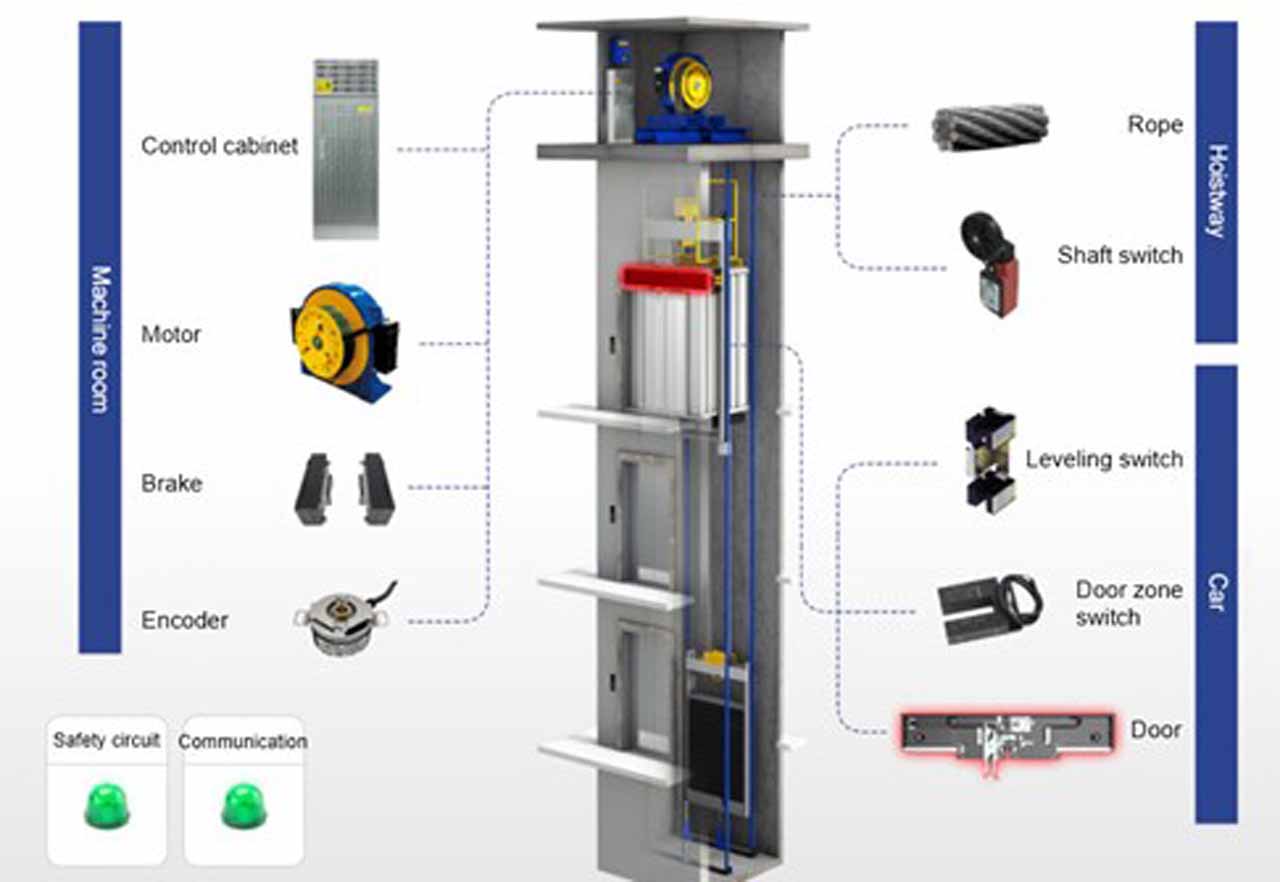

- Daily Report. Based on digital twin technology, the elevator cloud platform can detect safety hazards and problems and prompt alarms. Key events, faults and alarms can be intuitively displayed, as shown in Figure 2. Detailed reports can assess elevator operation and management status of the day. Daily reports can be classified into categories including equipment, environment, personnel, faults, trapped or elevator-stop alarms, operation statistics and preventive measures taken. Using the “equipment” category as an example, performance of the control cabinet, drive motor, brake, door, safety circuit, elevator communication system, elevator stop-leveling device, etc., can be conveyed. Using the “fault” category as an example, control results such as fault code, fault cause, solution, maintenance suggestions, etc., can be presented.

- Weekly and Monthly Reports. The statistical operation of elevators this week and this month is intuitively displayed in the form of charts, as shown in Figure 3. The detailed report can count the operation and management of elevators by the current week and by the current month. The report can be classified according to user requirements including operation statistics, faults, trapped or stopped alarms, equipment, personnel, management, rectification and verification of safety risks and hidden dangers the previous week, major safety risk and hidden dangers and rectification the current week, safety management evaluation the current week and work priorities for the following week. Using operation statistics as an example, it can reflect whether vibration exceeds the standard, cumulative operation times, cumulative wire rope bending times, cumulative door opening and closing times, power outage duration, maintenance duration, alarm times for help, etc. Using the “trapped” or “stopped alarm” category as an example, it can reflect the time of trapped or stopped alarms, the cause of entrapments or faulty elevator stops (if a fault occurs, the fault code, fault cause, solution, maintenance suggestion, etc., can be presented), the duration of entrapments or faulty elevator stops and end-time processing, etc.

Big Data Analysis Technology for Troubleshooting Safety Risks

The elevator cloud belongs to the IoT. It has the typical characteristics of the IoT, that is, the data growth rate of equipment operation is very fast, and concurrency requirements are also high. For example, a single elevator adds 3,000 pieces of log data 3,000 times per day. If 200,000 elevators have 600 million pieces of log data per day, that means 216 billion pieces of log data per year. The maximum capacity of a single piece of data is 0.0468 kilobytes, and the daily output is nearly 30G kilobytes of log data. The annual output is more than 10 terabytes of log data. Therefore, it is necessary to use a big data system to analyze and calculate such a large amount of data. Considering elevator industry characteristics, we chose the current mainstream Hadoop+Hive+Hbase solution as our big data solution. This solution uses the open source components of the big data ecosystem to build a big data platform. The advantage of this solution is that it is part of the active, open-source community. It is also flexible, lending itself to a DIY (do-it-yourself) approach. With the support of the big data platform, we can realize innovative functions such as real-time stream analysis, data mining, personalized recommendations and machine learning, in addition to traditional functions that provide more value to customers. These functions include:

- Control system core electrical data. Collect real-time operation data, fault data, event data, operation statistics, etc., through monitoring terminals. Cloud platform analysis helps improve the accuracy of elevator safety hazard inspection and dynamically scores the health of elevators.

- Vibration data. A car-top vibration collection and analysis device collects car vibration data and connects it to the control system, making the vibration sensor an important part of the elevator system. Vibration data analysis adopts the complementary mode of local computing + cloud computing.

Local Calculation

For obvious abnormal vibrations, the car-top vibration collection and analysis device can directly calculate the safety hazard code locally and report it to maintenance personnel through SMS or an application (app) pop-up window. Safety hazards that can be actively reported include emergency landing, emergency stop, start slippery, abnormal local vibration (uneven guide rail, out-of-round traction wheel, uneven force on wire rope) and abnormal continuous vibration (brake operation, guide shoe abnormality).

Cloud Computing

The vibration data collected by the car-top vibration collection and analysis device can be uploaded on demand or regularly through the machine room DTU. Once vibration data is uploaded to the cloud, cloud computing will begin. When an over-standard situation is found, the elevator cloud app can display the over-standard situation and send SMS and app pop-up window alarm prompts to maintenance personnel.

Door Machine Data

The reporting of door machine fault data can more accurately locate door system problems. On the basis of the inherent fault code of the original control system, the door machine system fault code is added, and maintenance personnel can be informed immediately when the door system is abnormal.

AI Recognition Data

The AI camera can be expanded to realize functions such as electric scooter recognition, long-time door blocking, passenger counting, audio and video intercom, etc. When abnormal behaviors such as electric scooters entering the elevator or long-time door blocking occur, the AI camera can activate audible and visual alarms and promptly send the information to property or maintenance personnel.

On-Demand Service Maintenance

By making full use of AI-based big data analysis technology for troubleshooting safety hazards, maintenance personnel are proactively reminded of safety hazards in elevators and can achieve on-demand maintenance. At the same time, with the digital maintenance function provided by the cloud platform, paperless management of the maintenance process and maintenance contracts can be achieved. Maintenance users can develop targeted maintenance plans based on monitored elevator operation conditions and track the process. The elevator cloud app can be used to add maintenance plans, pinpoint geographic locations, check maintenance items, upload pictures, text and recordings and perform other operations to improve maintenance efficiency.

Service Elevator Insurance

By making full use of big data analysis technology for troubleshooting safety hazards, the elevator cloud platform can generate statistics on the fault entrapment rate and fault stop rate, and can also summarize fault stop time, rescue response time, rescue time and other data to generate statistical reports.

Insurance institutions can dynamically evaluate the insurance premiums for elevators based on statistical reports generated by the cloud platform.

The elevator cloud platform can also handle spare parts management. When elevator insurance covers the need for parts replacement, this function can provide insurance institutions with parts quality assurance.

Service for Renovation of Old Elevators

The elevator control system’s core electrical data, vibration data, door machine data, AI recognition data and other important data — automatically generated by the elevator operation report after being obtained through elevator cloud technology — can provide data basis for the renovation of old elevators. Such reports can be considered for endorsement and certification by relevant institutions with block-chain trusted judgment technology, making the report more authoritative and recognized by relevant players in the renovation process for old elevators.

Conclusion

This article discusses the safe operation of elevators based on elevator cloud technology from the standpoint of system architecture and functions. Achieving safe operation of elevators urgently requires the support of digital means (such as elevator cloud technology). The investigation of elevator safety hazards is deeply consistent with the emergence of predictive maintenance in the industry. By extracting and deeply analyzing various types of elevator data (electrical data, vibration data, door machine data, AI recognition data, etc.), the accuracy of predictive maintenance will be greatly improved, and it can also lay the groundwork large-scale promotion of subsequent on-demand maintenance.

Reference

[1] statista.com/statistics/1201896/elevators-escalators-operation-worldwide

Get more of Elevator World. Sign up for our free e-newsletter.