An Instrument for Testing Elevator Balance Coefficient without Load

Dec 1, 2014

A device to aid the quick and accurate inspection of elevators is detailed.

by Lei Chen, Yihui Ruan, Yuandong Jiang and Qufei Zheng

With the development of society, the elevator has become one of the most important forms of transportation. At the same time, elevator safety and energy savings increasingly attract attention. Thus, the responsibilities of elevator installation and inspection departments have become greater.

Elevator balance coefficient, one of the most important elevator parameters, should be tested and inspected to reduce energy consumption and improve safety. The essence of such performance index is weight design for the counterweight. In the case of suspension lifts, the weight of the lift car will usually be balanced by the counterweight. Thus, if power is measured at the contract speed, the factor that affects the power consumption will primarily be the proportion of the full load balanced by the counterweight.

In the usual design of a lift machine, the counterweight is sized to balance the weight of the lift car, plus 40-50% of the rated load. This article introduces a new method for measuring the elevator balance coefficient without load. The instrument is characterized by having a simple structure, small volume, high response speed, low energy consumption and high reliability.

Principle of Measurement

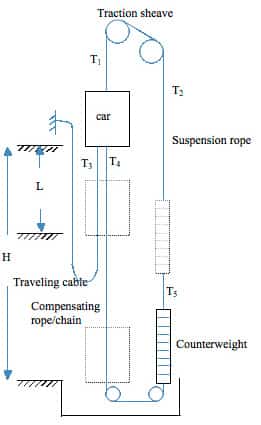

In a typical elevator (such as that shown in Figure 1), if the car stops at a landing other than the top one, then:

T1 = P + T3 + T4 + Lqy and T2 = T5 + (H – L)qy + W

T3= 1/2 (H-L)qd

T4 = (H – L)qb

T5 = Lqb

Thus, T1 and T2 should be:

where:

- L = traveling distance of car from top landing (in meters); considered a variable with the movement of car.

- T1 = tension force from one side of traction sheave (in Newtons).

- T2 = tension force from one side of deflection sheave (in Newtons).

- T3 = tension force at the joint from traveling cable below the car (in Newtons).

- T4 = tension force at the joint from compensating rope/chain below the car (in Newtons).

- T5 = tension force at the joint from compensating rope/chain below the counterweight (in Newtons).

- qd = mass of traveling cable per unit length (in kilograms per meter).

- qy = mass of suspension rope per unit length (in kilograms per meter).

- qb = mass of compensating rope/chain under the counterweight per unit length (in kilograms per meter).

- P = mass of empty car (in kilograms).

- W = mass of counterweight (in kilograms).

- H = travel height (in meters).

If buffers are oil buffers, the electrical switch shall be bypassed. The upper limit switch and final limit switch are also bypassed to allow the car to further move downward until the ropes slip on the traction sheave. The counterweight rests on its completely compressed buffer, and the counterweight’s mass (W) can be measured. Similarly, after the low limit switch and final limit switch are bypassed, the car can be operated to move downward, and the mass of the empty car (P) can be obtained.

If the car is at the highest level:

And if the car is at the lowest level:

where:

- Di = the total weight from the side of counterweight (in Newtons).

- Ji = the total weight from the side of car (in Newtons).

- Ff = friction force from the contact area between the sheave and rope (in Newtons).

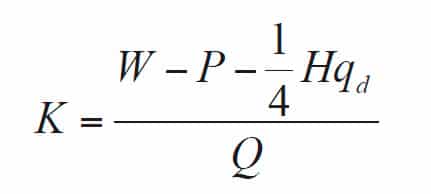

Supposing:

KQ=1/2 (Di-Ji)

we can have:

KQ=W-P-1/4Hqd

where:

- Q = rated load for the elevator car (in kilograms).

- K = balance factor indicating the amount of counterbalance of the rated load by the counterweight.

- K = elevator balance coefficient; this constant can be known according to W, P, H, Q and qd.

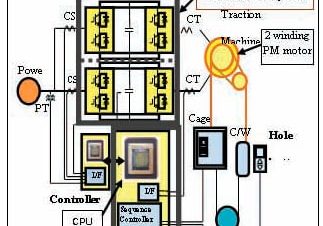

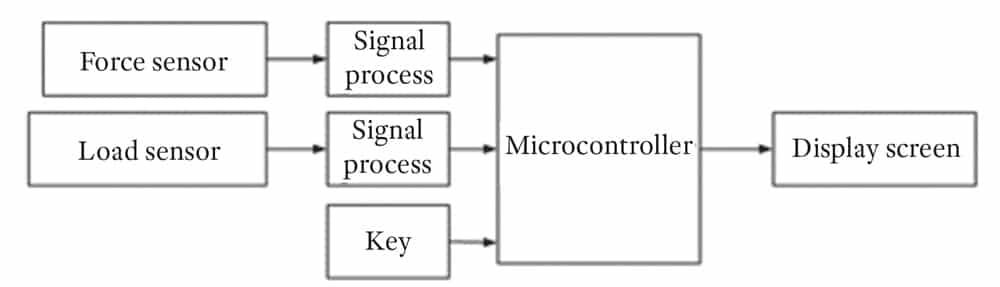

Hardware Design

Referring to its hardware composition in Figure 2, the elevator balance coefficient measuring instrument includes a controller module, human-interface operation module and sensor module. The human-interface operation module and sensor module are electrically connected with the controller module. The controller module is powered by an ARM embedded central processing unit (CPU). The sensor module is a flat dynamometer load cell. The human-interface operation module is intended to display system parameters and include digital display tubes and buttons for setting the parameters, a transistor output module, relay output modules and a real-time display of test data.

The ARM embedded CPU is for control of the central core. The chip comes with an analog-to-digital converter and CAN communication interface. Its main function is to force sensor output signal for sampling, storage, analysis and transmission. Sensor data is sampled and analyzed for processing, then a mathematical model of car and counterweight weight and balance coefficient based on the basic mechanics of the formula are derived through the internal procedures. Equilibrium coefficient values are output, while eligibility is automatically determined. Through human input, the controller can accept various input parameters of the operation module for storage, analysis and transmission.

Conclusion

The device makes use of sensor technology and a microcontroller to test balance coefficient without load. The elevator balance coefficient can be easily inferred according to the formulae presented. The received data from the sensors can be processed and calculated through microcontroller programming. Finally, the required data can be shown on the display. This method is helpful for those inspecting elevators quickly and accurately.

Get more of Elevator World. Sign up for our free e-newsletter.