An Instrument for Testing the Handrail Speed-Monitoring Device of Escalators and Moving Walks

Oct 1, 2013

by Xueming Chen, Jianfeng Sun, Wei Hong and Yihui Ruan

The stairs and handrails of escalators are designed to operate at the same speed and are driven by the same electric motor. The motor connects to a drive gear that moves the steps, and from there, a belt turns a wheel that drives the handrail. Although the handrail will ideally move at the same speed as the steps when first installed, it wears and stretches as it is used. As a result, the speed may change. Improper handrail setup, seized rollers, flat spots or contaminants on the handrail drive surfaces can all affect the speed.

EN 115-1:2008+A1 stipulates that the handrail speed monitoring device shall be provided and shall stop the escalator or moving walk in the event of a handrail speed deviation of more than 15% of the actual speed for more than 15 s. while an escalator or moving walk is in motion.

This article presents a new method for testing handrail speed-monitoring devices for escalators and moving walks. The testing instrument is designed for elevator installation and inspection. The utility model is characterized in simple structure, small volume, high response speed, low energy consumption and high reliability. Maintenance personnel for escalators and moving walks adjust handrail speed deviations of more than 15% of the actual speed. Inspectors can make use of this instrument to justify its validity of the handrail speed-monitoring device when the deviation timeout value is greater than 15 s.

The Principle of Measurement

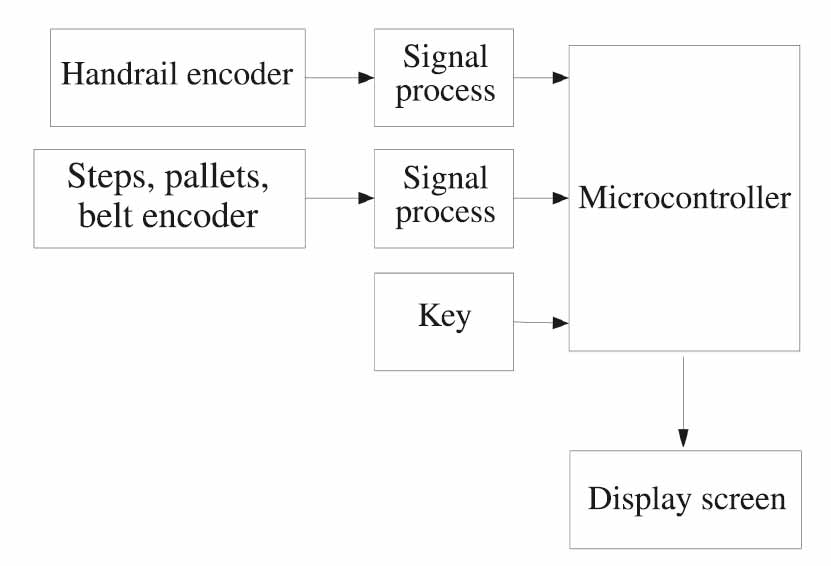

Figure 1 illustrates the diagram of a testing device. Its principle is:

v = (n/n0) X 2Πr ÷ t (Equation 1)

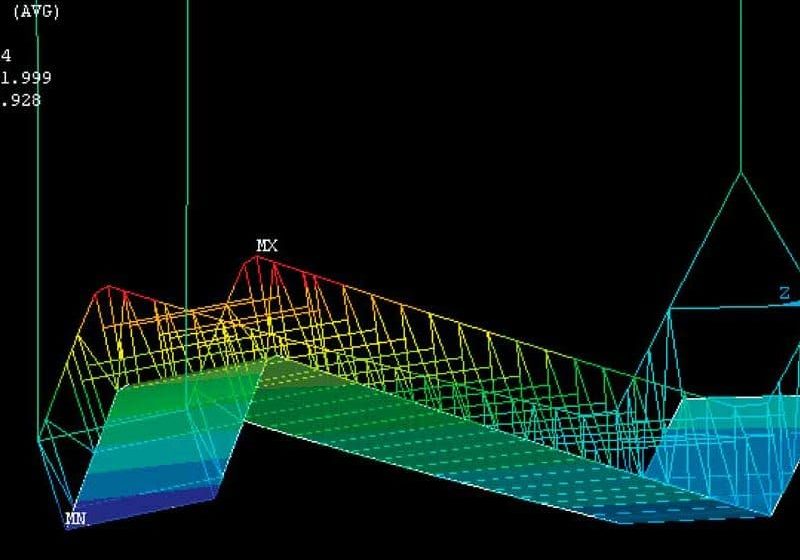

where n is the number of impulses a handrail or steps, pallets or belt encoder produces within time t; n0 is the number of impulses if a handrail or a step, pallet or belt encoder revolves once; r is the radius of the encoder; 2πr is the circumference of the encoder; and v is the speed of handrails, steps, pallets or belts.

Microcontrollers can monitor the speed of the handrail, steps, pallets or belts in real time and calculate handrail speed deviation to the actual speed of the steps, pallets or belts. The device uses the microcontroller containing a timer to judge whether its deviation is more than 15% and its timeout value is greater than 15 s.

The system is made up of handrails, steps, pallets or belt encoders, a microcontroller, a group of keys, a display screen and other auxiliary components. Its display screen (Figure 3) shows four values in real time in the process of a test. Once escalators and moving walks are tested and deemed unqualified, the device activates an alarm call. It not only makes the operation more convenient, it also provides a user-friendly interface.

Software Design

The microcontroller is embedded to implement an intelligent control algorithm. The pulse signals, which two encoders produce, can be converted to handrail speed and steps, pallets or belt speed values. The control software will be implemented in the programming environment of µVision4.

Conclusion

The device makes use of encoder technology to test handrail speed and steps, pallets or belt speed in real time according to the radius of the encoders. The received data from the encoders can be calculated through programming microcontrollers. The deviation between handrail speed and steps, pallets or belt speed can be judged. This method is intended to be helpful to inspectors by enabling them to inspect the handrail speed-monitoring device of escalators and moving walks quickly and accurately.

Get more of Elevator World. Sign up for our free e-newsletter.