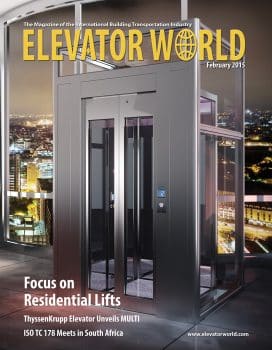

Bringing It Home

Feb 1, 2015

This Readers Platform traces the history of the modern residential elevator and looks to its future.

Elevators, once found primarily in commercial and institutional environments, in apartment buildings and the occasional private mansion, today are on the way to becoming mainstream in the individual residential space. No longer is it startling to see an elevator in a person’s home. For certain groups of people, residential elevators have become a widely adopted, central lifestyle component.

The seeds of this development lie in the socioeconomic trends of the early 21st century. By 2007, real estate was rapidly becoming more expensive, generating the need for smaller building footprints and more vertical construction. America’s increasingly aging, empty-nester population was tending to remain close to home – near family and friends – rather than retire to distant locations. All manner of structures – residential, combined units, townhouses, assisted living – were becoming shallower, narrower and taller, creating the need to comfortably convey older people to higher floors. Plus, prior to the economic crisis, this period saw the development of a luxury market, with people of means retrofitting elevators into their homes, and high-end homes being built from the ground up with de rigueur elevators included.

An early solution to elevate older and physically-challenged people was the stairway chairlift, a chair-like device that creeps up a rail mounted parallel to the stairs. Because they were in private (rather than publicly-accessible) space, these, and other forms of lifts, were not subject to many safety codes or fire regulations and presented corresponding limitations. But, an industry was about to be born and evolve.

Stairway chairlift and medical device manufacturers began thinking about making elevators, technically defined as enclosed conveyances in shafts that penetrate through floors. On these first, introductory residential elevators, very little was automated. To enter the lift, riders needed to manually open and close the swinging landing doors and slide the cabin scissor gates or folding doors to the side. Upon exiting (since there was no mechanized connection between the cabin gates and the landing doors), the rider needed to reach out and manipulate a doorknob to open it. Little structural accuracy or alignment was required in these early hoistways, since the human hand could find and turn the doorknob wherever it was located. This – compared to commercial, fully automated elevators featuring clutches to precisely grab pickup rollers on every floor – was far from ideal or safe and needed to change.

Changes soon arrived that would catalyze the emergence of the modern residential elevator. First was the Americans with Disabilities Act of 1990, which included federal mandates regarding vertical conveyances for public buildings of certain sizes and minimum capacity standards for lifts. This led directly to the development of a new elevator category, limited-use/limited-application (LU/LA), initially conceived for smaller commercial spaces with at least two floors but lacking the available hoistway space to install a full-sized commercial elevator. Except for their smaller size, LU/LA installations had to conform to all the existing commercial codes and requirements, which, by definition, meant that the doors had to be automatic. This would require the development of door-operating equipment that was smaller than the commercial sizes then available.

Simultaneous with the emergence of the LU/LA segment, the residential field began to mature, and codes began to drift toward commercial requirements and the growing use of automated doors. Safety became an increasing priority, with, for example, a hard look at the size of the gap between the back of swinging landing doors and folding/collapsible car gates, in which children and pets were becoming trapped and injured. Automatic doors, because they moved together in the same direction, would help to ameliorate this problem.

Enter companies such as Elevator Solutions International, acquired by Columbia Elevator Products, to fill this niche and bring smaller, more-compact door operators to market. L.J. Blaiotta, Jr., president of Columbia, explains:

“Through a partnership with Spain-based Fermator and our own initiatives, we developed a product we called ALURE™, which stands for ‘Automatic Limited Use Residential Elevator.’ The new availability of such reduced-size door-operator equipment created demand for ‘real’ automatic elevators in the home, where space was limited, especially in retrofit situations. Out were scissor gates and pre-hung landing doors with doorknobs, and in was the move to home elevators with automated doors. Installation tolerances and safety standards had to be tightened up to commercial levels. With the old/manual-type installations, if you were off by 1/2 in., there was no consequence, but now it all needed to be exactly precise. If you’re off by 1/2 in. with an automatic door operator, the clutch is unable to engage the pickup roller, and the door won’t open properly.”

The typical residential lift companies entering the automatic elevator space were not accustomed to selling the door side of the business. As Blaiotta explains:

“In manual applications, it was usually the responsibility of the homebuilder to install the landing doors. This was fine with the lift companies, since the landing doors were not included in the elevator package, which kept down their cost. But, later, as the market evolved to demand/expect automatic/power-operated door systems, the residential lift companies began to experience difficulties. Since homebuilders weren’t familiar with the tolerance requirements of door operators, interlocks, clutches, etc., the hoistways were often built so out of whack that there were serious inconsistencies from floor to floor. For the residential-elevator business to mature and meet growing demand, these problems needed to be eliminated, and updated equipment began reflecting this.”

At first, commercial-elevator companies attempted to fill this need with LU/LA-sized elevators fabricated to commercial standards. By making everything smaller, their thinking went, they could dip their toes into the residential market and effectively compete with the typical residential/stairway-chairlift/platform-lift companies attempting to edge their way into the fully automatic elevator business. But, the migration wasn’t as easy as initially hoped, especially when the commercial-elevator companies attempted to shrink their offerings to residential sizes that were even smaller than their LU/LA product lines. Faced with the tiny shafts originally specified by the lift companies, the commercial providers soon realized that their products would not fit into such limited spaces.

“That’s where we came in,” explains Blaiotta, continuing:

“At Columbia, our initiative was to dramatically shrink the power-door operating equipment to fit into spaces that previously could only have been addressed with the use of collapsible car gates and swinging landing doors. On the landing side, we decided to mimic the space requirements of a swing door by pushing the sliding door inside the wall, creating, essentially, a pocket door. This ‘InWall’ entrance was a much more space-efficient solution than what is found with a standard commercial elevator entrance that sits on an angle inside the hoistway. The commercial sill support angle is, in essence, a little ledge upon which the doors slide back and forth, behind a fire-rated wall. For a single-slide/one-door panel application, we’d waste between 4 and 5 in. of valuable hoistway space, and, for two-speed doors, between 5-1/2 and 6-1/2 in. By contrast, a residential wall is not fire rated, enabling us to make the wall thinner to save space. And instead of placing the doors on an angle in the hoistway to slide behind the wall, we placed the doors up onto the landing, thereby removing the swing door and installing an elevator pocket door in its place. Being able to place our InWall entrances into the corridor wall saved critical space and went a long way toward enabling the installation of elevators with automated doors in narrow residential hoistways.”

While the InWall approach was a major breakthrough on the landing side of this solution, there were also cab-side issues to consider, as Blaiotta explains:

“The typical residential elevator has the lifting mechanism on one side of the car, which leaves a natural 10 to 12 in. or so of space between the edge of the platform and the side wall of the hoistway. We needed to figure out a way to open our solid car-door panels and still fit into that space without hitting the side of the hoistway. We couldn’t go with a single-speed door, because there was insufficient space between the edge of the platform and the hoistway wall for the door to fully open. Two-speed doors, likewise, were too large to open all the way. It wasn’t until we went to a three-speed door arrangement that the panels became small enough to fully open without hitting the hoistway wall. Of course, with each addition of a speed, the door space becomes 1-1/2 in. thicker, consuming 4-1/2 in. of platform space with a three-speed configuration. Combined with the 2 in. or so of room required behind the doors for the traditional commercial clutch, this added up to a good deal of ‘wasted’ space that we sought to minimize.”

The answer was ALURE, as Blaiotta explains:

“With ALURE, we moved the clutch away from the back of the door and, instead, placed it above the door opening in the pendant/hanger space. By doing this, we are able to offset the doors and eliminate 2 in. of wasted clutch space behind the panels, thereby bringing the doors directly to the edge of the sill. In the same space where homeowners previously had folding wooden doors, they now enjoyed power-operated doors that work without hitting the hoistway wall. Additionally, on the aesthetic side, moving the clutch above the opening allowed for the use of architecturally advanced glass doors on the hoistway and car, yielding an unobstructed view, free of any door equipment.”

According to Blaiotta, the ALURE operator provides several additional advantages over the typical commercial operator. Because they feature a linear drive system, he explains:

“ALURE operators take up much less height than a typical commercial operator that drives the doors with a harmonic link-arm arrangement. In addition to consuming much less overhead space – often severely limited in residential applications – the linear operator is much lighter in weight than its harmonic counterpart, a critical factor for the lighter-duty lifting capacities of the residential marketplace. The technological advancement of quiet, energy-efficient, compact and lightweight linear door operators like ALURE, paired with the space-saving advantages of InWall entrances, have helped bridge the gap between the tight space requirements of residential applications and the fully automatic, power-operated door systems of the commercial marketplace.”

Today, demand for elegant, automatic and relatively problem-free residential elevators appears on track to grow stronger. With the economy on the rebound, higher-end houses are being built and sold, including automatic elevators with power-operated door systems. While “old-school” manual installations remain available, increasingly more companies are beginning to shy away from them, if only for the potential liability issues they present. And, among end users, there is a growing appreciation that, if a person needs a home elevator for accessibility, automatic/power-operated (rather than manual) doors are exceedingly more useful and beneficial.

Concludes Blaiotta:

“It’s all trending upward for the residential market. While Columbia is not in the residential cab business – but rather in the business of supplying car fronts to companies that build their own cabs – it’s something we’re happy to see. Societal aging and affluence are driving this trend, certainly a positive for our industry. It would not surprise me if, within a couple of decades, the home elevator becomes as universal as the automatic garage-door opener is today.”

Get more of Elevator World. Sign up for our free e-newsletter.