Cable Cars

Jun 1, 2021

Dr. Tomasz Magiera (TM), ropeway expert and project manager, Cable Car Solutions GmbH of Heimenkirch, Germany, shares insights with your author (SSP) on the significance of this mode of transportation.

Dr. Tomasz Magiera is a technical specialist in cableway engineering and holds a PhD in this specialization. He has worked as a cable car consultant with clients on six continents. Moreover, he holds lectures about cable cars and conducts research at the University of Science and Technology in Krakow, Poland.

SSP: What are the history and evolutionary process of the cable car concept?

TM: The basic concepts of cable cars have served people for more than 2,000 years. The convenient and straightforward solutions contained a rope and bucket with manpower, allowed to transport people, animals or goods over rivers, gorges or other difficult terrain (Figures 1 and 2). Such countries as India, China, Japan and Peru are known as pioneers in historic ropeway solutions.

The gamechanger in the history of the rope and ropeway industry was 1834, when a German mining official named Wilhelm August Julius Albert invented steel rope. Initially used in mines, it was later implemented in cableways, which it significantly revolutionized. Next came improvements in the tensioning of ropes (by Luis Zuegg) and bi-cable cars (by Adolf Bleichert).

Cable cars spread all over the world in the last century. From the streets of San Francisco (Figure 3) through European Alps summits and cities, they have served as a reliable means of transportation. Nowadays, their application is broader.

SSP: Where may cable cars be implemented?

TM: Ropeways, in general, are suitable means of transportation for hilly regions, which is fully justified. The ease of reaching summits in different weather conditions with a relatively high passenger capacity and low energy consumption made mountainous areas a “natural habitat” for cableways.

Every height difference level between starting and ending points (even a small one) creates an opportunity to implement ropeways to provide an efficient transportation connection. The lack of transportation infrastructure in mountains and limited ground access due to natural obstacles (such as trees, steep terrain and rocks) make cable cars a favored way of getting to the tops. Rope-propelled systems in Europe and the U.S. are rather unambiguously associated with a technical infrastructure required for skiing or snowboarding. Winter tourists can easily get to the top by cable cars, chairlifts or funiculars and ski down. However, cableways serve not only in the wintertime; they are reasonable solutions for summer tourists who would like to start hiking from a certain level, have mobility limitations or are elderly.

SSP: In which types of locations or sites may cable cars be utilized?

TM: Ropeways are used as an efficient solution to get to historical places, worship areas and temples or tourist attractions to which access is very limited. Good examples of such Asian ropeways are India’s Mansa Devi Udankhatola (from the Holy City of Haridwar to Mansa Devi Temple at the top of a hill) and China’s Mutianyu Great Wall (from a visitor’s center to a level of the wall).

Moreover, aerial ropeways have one more advantage compared to standard means of transportation: flying from a few meters to hundreds above the ground, they deliver unique and unforgettable experiences, especially in mountainous regions. From an owner’s point of view, they can be profitable attractions.

Cable cars are not only used for people transportation, but also serve as an efficient way to transport goods (even over very long distances, such as the 96-km-long Norsjö, Sweden, ropeway). Some operators find unique but exceptionally utilitarian solutions for their ropeways, such as a cable car that transports a garbage truck to and from Bettmeralp, Switzerland.

Cableways are increasingly implemented in cities, recreational parks and other isolated tourist areas. Reasons for installing them include financial aspects (low capital expenditures and operational costs compared to those of other means of transportation), quick construction, small footprint, technical and operational reliability, and quick return on investment.

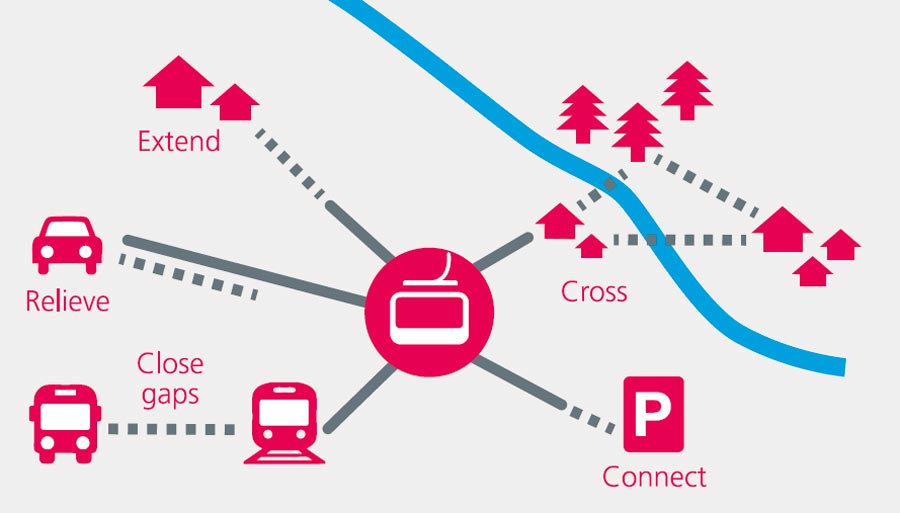

Cableways can complement existing city transportation systems, especially where traditional means of public transportation cannot be used or have already achieved their maximum capacity and cannot be expanded. Their aerial aspect can also solve issues with traffic jams by relieving congestion, closing a gap between existing means of transportation and crossing natural obstacles (Figure 4).

SSP: How can cable cars be implemented in urban areas, and what are the benefits and drawbacks?

TM: Advantages of urban ropeways are right-of-way and the possibility of implementing them in very dense cities. Cable cars can fly over traffic jams or rivers, or climb hilly terrains without problems. In the most common urban cable car system, monocable gondola detachable (MGD), cabins arrive at the station approximately every 10 s, which reduces gridlocks at waiting areas or platforms (Figure 5). As passengers enter cabins, they move slowly (approximately 0.25 m/s). Moreover, there is no level difference between platforms and cabins, which makes an entrance barrier-free for older and disabled people or parents with trolleys and small children (Figure 6). During the ride, most of/all the passengers are seated in the cabins, and during harsh weather conditions, special active and passive systems can be implemented to regulate temperatures.

Some opponents of cable cars say there are two main drawbacks of urban systems. First, it is not possible to change the route once it is selected or increase final capacity after construction without significant investments. Second is claimed evacuation issues, considering cable cars are 80 m or more above the ground.

Proper planning during prefeasibility or feasibility studies can reduce the risk of the first situation. For the second, evacuation can be carried out by an additional emergency drive, reducing the risk of being stuck in a gondola to a minimum.

Cableways can also be solutions for transportation in parks or zoos. For example, the Swedish Kolmarden Zoo’s one-direction system (Figure 7); other zoos in Australia, the U.S. and China; and the Hogwarts Express in Universal Studios in Orlando, Florida. They can also be used as attractions in caves or aquariums (i.e., special funiculars with glass roofs) or as a connection between islands.

SSP: What goes into planning a cable car system?

TM: Taking into consideration that ropeways are designed for 25-30 years of operation, a few things should be deeply investigated and assessed during planning. At the beginning of the process, basic information, such as the main purposes of the planned cableway and a definition of the most suitable places for stations — chosen as the results of multicriteria analyses and assessments including future predictions — must be clarified. The crucial parameter is capacity. Other important considerations are local transportation habits; nearby religious or other places of interest; and a nearby cable car route(s). From our experience, it is a must to have a site visit and carry out an appropriate survey during planning.

Moreover, a few route concepts defining all significant obstacles and assumptions to safety corridors for a defined type of a cable car should be created. While the route and parameters are fixed, the next step involves technical rope-line calculations and creating a rope-line profile. At this stage, there are also possible iterations, which can be done to tailor the project in more detail. There should also be architects and other significant consultants involved in the planning processes. The next steps should be based on creating the final project in cooperation with the manufacturer. Once necessary permits are obtained, construction may start.

SSP: What would influence investing in such projects?

TM: Analyses of pros and cons should support every investment. In addition to ropeways’ strong points already discussed, reversible movement; low energy consumption per passenger and low carbon footprint; an ease in overcoming obstacles such as mountains, rivers and lakes (Figure 8); the possibility of overcoming gradients more than 100%; accessibility; capacities exceeding 6,000 people per an hour per direction; and speed up to 14 m/s.

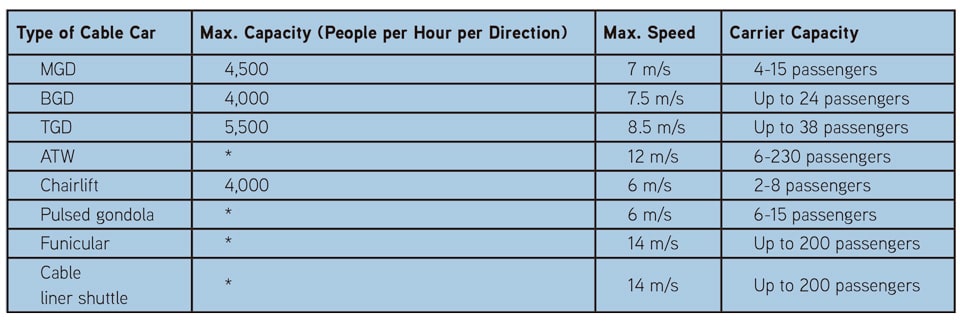

Cabins can move in a circular or reversible motion in the air or on the ground. The main types of cable cars are:

- Aerial with circular movement: MGD, bi-cable gondola detachable (BGD), tri-cable gondola detachable (TGD) (Figure 9)

- Aerial with reversible movement: aerial trams (ATW) (Figure 10)

Aerial cable cars are also chairlifts and pulsed gondolas. The first, based on circular movement, has chairs that transport passengers upward. In contrast, a pulsed gondola is a group of cabins that stop when a car reaches a station. Grounded cars are funiculars and cable liner shuttles, which serve mostly in cities as a tourist attractions or intra-airport transportation. Their basic technical data is described in Table 1.

SSP: What are the current trends in the industry?

TM: Ropeway trends are aimed at increasing capacity (especially in urban areas) by means of increasing operating speed and cabin size. The level of travel comfort is still being increased (i.e., air-conditioning and panoramic cabin windows). Some worldwide companies also work on hybrid cable cars (a mix of features of a car and a cable car), which should eventually be sufficient for cities.

SSP: What are the main ropeway components and their implications?

TM: Main components or subsystems of every type of cable car are stations (with drive machinery and tensioning) and route elements (towers/tracks, ropes and carriers) (Figure 11). All components are continuously technically modified by manufacturers to achieve better operation parameters (i.e., less wear or reduction of unwanted vibrations), a higher level of safety and operational accessibility.

Stations, from a technical point of view, are equipped with electromechanical parts and command rooms in which control infrastructure is installed. Other station equipment may be matched to investors’ aims and expectations. The minimum station dimensions are defined by electromechanical infrastructure and safety regulations. As a result, stations of the same type of ropeway can vary in size. They can be very minimalistic (limited to equipment size) or quite extensive, integrated with big malls or even be perceived as architectural works of art. A standard station solution is a level walk-in (no height difference between platform and cabin levels) (Figure 6). This allows older or disabled people to easily enter and leave cabins safely.

Type, height and number of towers depend on general parameters of the chosen cable car system, the terrain profile and results from a local survey of the area, and its assessment and investors’ expectations. However, the detailed tower parameters (right height, number of sheaves or size of foundation) are results of technical calculations. Towers, in terms of construction, are usually tubular or trusses. However, there are no barriers to create them or even create an additional attraction based on them (i.e., a small restaurant).

Ropes are selected as a result of technical calculations and initially adopted parameters. Notwithstanding, rope manufacturers implement different technical solutions, which reduce levels of noise and vibrations. This lowers operational costs.

Carriers and cabins depend on cable car types. Every cabin can be equipped with communication systems and even digital entertainment. Energy can be delivered from solar panels mounted on a cabin’s roof, capacitors at stations or even generated by rotating cabin wheels. Cabins or carriers may also be used (unusually) as saunas or sky restaurant tables for business breakfasts or evening dinners.

SSP: What is the significance of systems and processes for the operation and maintenance of ropeways?

TM: Cable cars are characterized by a very low space impact. Towers need only a place for foundations. (There are some solutions to decrease this space to a minimum). Depending on the type of cable car, a garage may be required. Small warehouses for spare parts and maintenance workshops may be placed in a garage area or in station buildings. Stations should be equipped with command rooms, in which all electric cabinets are located. To run a cable car, electric power needs to be provided to stations.

Cableway operation and maintenance teams need appropriate training before being allowed to work (Figure 12). (Additionally, some countries require official exams.) Cableways are subject to periodic reviews determined by legal regulations in individual countries and based on the manufacturers’ guidelines.

SSP: Which have been some of the noteworthy innovations in the industry over the years?

TM: Cable car technology changed significantly, but the main concept and basic elements of stations, ropes, towers and cabins, have persisted. Technical changes, which we may perceive as innovations, focused on the increasing level of safety and comfort of passengers and staff. The most significant in recent years include:

- Detachable ropeways: cabins slow at stations and travel at full operating speed between stations.

- An increase in speed of aerial cable cars — up to 12 m/s (approximately 43 km/h).

- The 3S (TGD) cable car system, a mix of solutions from reversible and circular cable cars (Figure 13)

- Special sensors at towers and in stations to help increase the level of safety

- The development and use of non-destructive tests of technical parts

SSP: Which cable car technology would be suitable for India?

TM: The Indian market is very interesting in terms of implementing cable car systems. Chosen places should determine the right technology for future installations and set goals.

India has many opportunities for cable cars. Dense urban areas, and beautiful hills, mountains and parks are suitable for aerial systems. Urban cableways may be very useful, especially in cities where there is no opportunity for further ground development. Monocable systems would likely be the most suitable for Indian cities in terms of functionality and capital expenditures. But, there may also be a good application for BGD or 3S systems where distances between towers need to be significantly longer, and higher capacity is required.

When it comes to places of worship, or places located higher, where city residents can breathe air of better quality, the right cable car system depends on the adopted business model, and assumed capacity and possibilities of future development (considering additional attractions). MGD systems or aerial trams might be the best solution. Larger city parks or zoos will probably look for MGD or combination solutions with gondolas and chairs as vehicles. However, to select the best system for a site, technical and financial analyses with aspects of the present and future development should be performed. The most appropriate system should then be selected on the analyses’ basis.

SSP: How would you describe the role of cable car consultants?

TM: In our work, we often cooperate with different groups of consultants (architects, engineers or traffic/city planners) responsible for various project elements. The groups are usually responsible for parts of the construction infrastructure of the cable car, as well as the entire master plan for urban areas, parks or resorts in the mountains, or zoos (Figure 14). From our experience, it is challenging for them to work without support, especially considering that cable cars are not part of standard consultants’ education as a means of public transportation in cities or are only described in a very general way.

Our support during a project can be beneficial for investors. The scope of our professional engagement depends on the level of understanding cable car systems and experience. As the result, we work together to find the best-suited solutions considering financial assessment, which includes not only capital investment, but also long-term operational costs.

As part of our work, for all projects, we begin by describing all possible cable car systems with pros and cons. With other consultants, we set the preliminary conditions of the project and choose the best. What we find the most challenging is to switch the mindset of other consultants to the idea that a cable car is a machine a few kilometers long. To achieve success in the design phase, we have to define specific parameters at the beginning very precisely. If this does not occur, it may generate lower profits or higher costs for the owners during operation.

We have worked with consultants with different levels of understanding of cable cars. However, with less-experienced teams, to save money and time in projects, it is better to engage ropeway consultants at the earliest possible stage. In the scope of our work, we guide other consultants, investors and future operators from the very beginning, describing limitations of cable cars and requirements that must be provided. These allow consultants to start designing stations and cable car routes surrounding areas closely aligned with the goals and capabilities determined by the cableways and investor expectations.

Our work, as cableway consultants, does not finish at the designing phase. We also help our clients with preparing the most efficient tenders and commissioning a new ropeway. Additionally, for existing installations, we may provide a technical assessment of the condition of cableways with the possibility a valuation for sale. Finally, we offer staff training. The cost of this, in our experience, may be returned through lower maintenance costs, which is ensured by higher service team quality.

Examples of Cable Cars

Cable cars have changed over the decades. Modern systems provide reliable, safe and economical solutions to provide sustainable transportation in cities, or a fast-track to the tops of mountains or to unique attractions. Dr. Tomasz Magiera says finding the best cable car solution for certain areas should be preceded by a multicriteria analysis, which also considers the expectations and goals of investors and future development. The following examples illustrate the importance and potential of the technology.

Urban Cable Cars

La Paz, Bolivia

La Paz is a role model for urban cable car networks (Figures 15 and 16). It already has 10 lines, 36 stations and almost 1,400 gondolas in service every day. Monocable gondola detachable systems play the role of the most efficient and ecological public transportation. Every day, the 30-km-long MiTeleferico network transports thousands of La Paz and El Alto inhabitants. The average cable car capacity is 3,000 people per hour per direction.

Moscow

The ropeway installed in Moscow is classified as an urban solution but is also a great attraction for tourists (Figure 17). The route consists of three stations and may transport 1,600 people per an hour in 35 cabins and 10 chairs.

Ankara, Turkey

Flying over blocks of flats in hilly city districts may bring many advantages in every day commuting. The perfect example of it is a ropeway system in Ankara (Figure 18). There are three sections with a total length of 3.2 km. Four stations are connected with local means of transportation (buses and metros), and the capacity of the ropeway is 2,400 people per hour per direction.

Tourist Cable Cars

Hon Thom Cable Car, Vietnam

An excellent example of a connection between islands is a 3S cable car in Vietnam (Figure 19). Considered the world’s longest 3S cable car, it connects the Phu Quoc and Hon Thom two vacation islands. The tri-cable system offers not only unforgettable views for tourists, but also high wind stability and low power consumption. The cable car is 7,900 m long and has 69 cabins that provide a capacity of 3,500 people per hour. The trip time is an estimated at 16 min.

Disney Skyliner Cable Car, Orlando, Florida

This monocable gondola serves as a transportation solution and attraction at the Walt Disney World Resort in Orlando (Figure 20). Magiera considers it “the best transportation solution for park guests.” It has approximately 300 cabins suited for 10 passengers each.

Mountain Cable Cars

Zugspitze, Germany

The Zugspitze Cable Car provides amazing views and unforgettable experiences, while climbing almost 3 km above sea level (Figure 21). The ropeway, an aerial tramway with two 120 person cabins, travels at 10.5 m/s.

Penken Cable Car, Austria

This tri-cable car system serves tourists and skiers to get to higher parts of the Penken mountain and nearby mountains. Passengers may change to other ropeways or enjoy beautiful views from a restaurant. The 3S system is unique in technical solutions applied. It has the only curved tower (at 6.5°) of such a ropeway. The ropeway has a capacity of 3,360 people per hour, and 30-people cabins travel with a speed of 7.5 m/s for almost 3 km.

Get more of Elevator World. Sign up for our free e-newsletter.