California Cool in Dubai

Mar 5, 2019

DAMAC Towers by Paramount is a “crown jewel” with a VT system by Toshiba Elevator Middle East.

Growing into one of the foremost luxury real-estate developers in the Middle East, DAMAC Properties has joined forces with well-known brands such as Versace, Fendi and Bugatti to offer private apartment towers. Among such high-profile ventures is DAMAC’s latest “crown jewel,” DAMAC Towers by Paramount, consisting of a five-star hotel and serviced hotel/apartments.

Developed by DAMAC Properties in collaboration with Paramount Hotels & Resorts, the complex boasts four, 250-m-tall towers with one-, two- and three-bedroom apartments and hotel rooms that embody Hollywood glamour and the California “cool” lifestyle.

For the Tower C elevators, Paramount Hotel architects required that cab interiors match the rose-gold-accented lobby.

While one tower houses the five-star hotel operated by Paramount Hotels & Resorts, the other three have serviced apartments operated under the DAMAC Maison brand. The towers are on Al Khail Road overlooking the Burj Khalifa and the Dubai Water Canal. KEO served as construction consultant, and TAV Construction was the general contractor. Longtime DAMAC collaborator Toshiba Elevator Middle East was selected to supply the vertical-transportation (VT) system, providing 34, 5-mps elevators for the towers and two elevators for the podium.

The serviced apartments, Towers A, B and D, are served by six passenger and two service elevators each. The elevators were initially designed to serve all floors, but later redesigned as separate low- and high-zone elevators. The low-zone elevators serve floors one-34, and the high-zone elevators, 35-60. The basement/parking levels and the area from ground to podium level are served by both elevator groups.

Both the low and high zones are catered to by three sets of high-speed passenger elevators, each with a 1150-kg (15-person) capacity, based on the building’s occupancy design requirement and a traffic study. Two elevators dedicated to all building-related services serve each tower. Each of these units has a capacity of 1350 kg (18 persons). The 72-stop service elevators serve all floors. Both passenger and service elevators have a peak travel speed of 5 mps.

The Paramount Hotel will operate in Tower C and is served by eight passenger elevators. The VT system for this tower was also redesigned for low and high zones, with three elevators serving floors one-23 and five serving floors 24-60. Each elevator in the low-zone, three-car group has a capacity of 1600 kg. Each elevator in the high-zone, five-car group has a capacity of 1150 kg. Elevators in both zones have a peak speed of 6 mps. This tower also has a pair of service elevators serving all floors, with a peak speed of 5 mps.

For the Tower C elevators, Paramount Hotel architects required that cab interiors match the rose-gold-accented lobby. Toshiba supplied rose-gold, hairline-finish entrance assemblies with anti-fingerprint coating. Rose gold was also incorporated into the hall buttons and hall lanterns. Special stainless-steel sills complete the look, combining durability and aesthetics to match the surrounding features.

All elevators were designed per EN 81-1 and ASME A17.1 code, and can operate during seismic events and fires. Seismic sensors for primary- and secondary-wave earthquakes are applied in the lift pits to comply with the project requirements of a Seismic Zone 2. Seismic restraints are provided for equipment in the hoistway and machine room, as required by A17.1. The design of the entire rail and bracket system was calculated based on seismic code requirements, which included incorporating higher-capacity rail gauge and special fishplates.

In line with U.A.E. regulations, all landing doors and entrance assemblies have a 2-hr. fire rating certified by TÜV-SÜD PSB in Singapore. All control panels were tested at the Toshiba factory to comply with Electro Magnetic Compatibility (EMC) tests per EN 12015 and 12016.

The high-speed permanent-magnet motors and control panels for all the elevators were supplied from a Toshiba-owned factory in Tokyo. These motors have built-in thermostats to monitor motor temperature and are equipped with overspeed governors for ascending cars. A special rope-brake system acts as an additional safety device to protect the cabin from traveling above the rated speed.

The design of the entire rail and bracket system was calculated based on seismic code requirements, which included incorporating higher-capacity rail gauge and special fishplates.

Toshiba supplied wind-sway sensors for this project, wherein the sensors in the top machine room signal elevators to reduce speed or to stop at safe landings in case of building sway due to high wind.

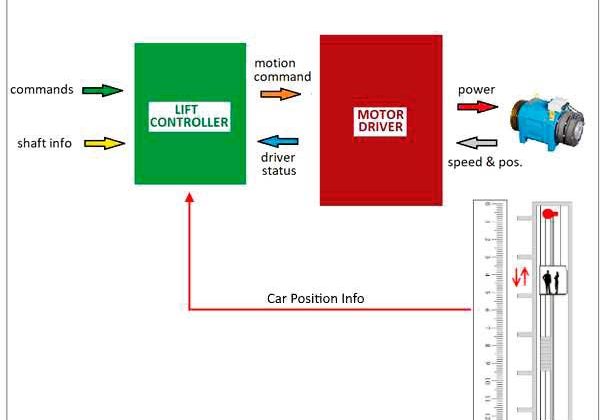

Elevators throughout the project are monitored by two Toshiba elevator-monitoring systems, which provide real-time information, such as elevator position, direction of travel and emergency status, via a pair of LED panels. There is an interphone system for the entire project. A power selector switch allows property managers to choose which lifts should be fed with generator power in case of power failure.

The regenerative power system reduces power usage by redirecting energy generated by the traction motors during various stages of cabin load. Conventionally, the energy generated during braking is dissipated as heat in the resistors, but this energy feeds energy back to the grid or drive system.

Elevators’ leveling/landing accuracy hinges on factors such as rope stretch and building concrete compression in the Gulf Cooperation Council region. While the leveling sensor is normally fixed to the rails, these factors can result in landing inconsistencies. In response, Toshiba provided landing-level sensors on the sills that automatically adjust to rope and concrete variations.

Many people were involved in the success of this project, including Toshiba Project Manager Khadar Jarith with the support of then-Senior Project Manager Mohamed Ibrahim, who handled coordination between the Tokyo factory and the Dubai jobsite. An array of engineers and safety specialists also played big roles.

Get more of Elevator World. Sign up for our free e-newsletter.