Carriage Gates

Jun 1, 2018

History, codes and revised code-related design principles important for all North American tradespeople involved with private-residence elevators’ entrance safety devices

This article is intended to help people in the trade understand the evolution of private-residence elevators’ entrance safety devices, known as carriage gates. Attention will be paid to the safety code, history of issues, available products and some design principles related to the revised safety code. There have been some serious tragedies due to issues in this area, and, consequently, all tradespeople, as well as companies working in this space, should be aware of these issues and looking to adopt practices that will reduce risk and potential liability, while ensuring the safety of the users of these products.

Learning Objectives

After reading this article, you should have learned about:

♦ The history and purpose of the carriage gate

♦ The available configurations of carriage gates

♦ Issues that surround carriage gates and landing doors

♦ How codes and code changes affect the design of new carriage gates

♦ How gate panel deflection is calculated

Background

Much of the design and development time for elevator products is focused on safety. This includes safety for the system itself, but, more importantly, for the users. Part of the concern with elevators is that they operate automatically. This means that once you press that button and a light is illuminated, the elevator will run through a set of instructions in the controls to move the carriage to a specific position. Because the machine is automatic, it will attempt to do this movement, regardless of anything in the way, unless safety devices and control structures are put in place to stop it from moving if a person is in a position that they could be injured or killed during this routine.

In most industrial settings where there is automation of machinery, people are not allowed near such machinery without significant safety guards in place. For instance, an automated robotic welding arm or an automated assembly robot typically has an entire cage built around it to ensure that no human can get in the path of its movement (Figure 1). Obviously, putting a cage around the entire elevator and avoiding contact with people defeats the purpose of it.

For elevators, the equivalent of a “cage” is the doors at each landing that separate people from the shaft (and potential falls), as well as the carriage where people enter and ride the elevator. The carriage is typically constructed from solid walls, but, to enter and exit the elevator, there needs to be an opening and, thus, a device of some kind to close off that opening so people do not enter and exit during elevator operation. This device is called a “carriage gate” (sometimes reduced to “car gate” or simply “gate”) in the elevator trade.

Carriage gates are also intended to avoid any potential pinching of extremities during movement. Due to the need for clearance between the moving carriage and shaft walls, there is an inevitable pinch point created, and the only way to avoid pinching hazards is to have a complete physical barrier between the people inside the carriage and the area around it.

While the ASME A17.1/CSA B44 code governs a variety of elevating products, there are significant differences between what is required for a residential/private-residence elevator and a commercial/public elevator product. One might ask, “Why is there any difference?” Simple differences include limits of residential elevators in floor area, weight capacity, travel speed and travel distance.

These are some practical differences, simply because a private residence does not typically need the carrying capacity one would see in a commercial/public setting. Also, few private residences would need more than 50 ft. of travel. This does not preclude someone from putting a fully compliant commercial elevator in a private residence, but that would be an uncommon installation, indeed.

Due to private-residence elevators’ greater limitations, the safety code for elevators in North America has different (though similar) options and requirements for them. A17.1/B44 Section 5.3 applies to private-residence elevators. While other parts of the code are referenced, this section is the portion that guides the specific needs for private residences, and there are sections that apply to carriage gates.

There are several carriage-gate configuration options available on the market, and, although there may be some special offerings out there, the following list is intended to comprise a substantial majority of what has been and is used. These options are required to have a safety switch that tells the elevator control system whether the gate is in the open or closed position. If it is in the open position, the elevator control logic should prevent movement of the elevator carriage.

Sliding Door/Gate

The sliding door/gate arrangement is exactly what it sounds like and is what most people think of when they think about elevators. There are private-residence versions of sliding door and gate sets on the market. Most of these offerings include automatic operators like in commercial elevators, but they may be reduced in size, and, in most cases, the doors are not fire rated. The sliding door/gate product is typically the most expensive option for a private-residence elevator, and, in many cases, the doors and carriage gate, along with their operator, could cost more than the rest of the elevator combined. As such, the sliding door/gate arrangement is not as common in private-residence elevators as some of the cheaper options noted below. Figure 2 is an image of a sliding door arrangement.

There is a variety of suppliers for sliding door sets, but one of the more cost-effective options for private residences is a product from Victory, an Italian company, that is distributed by OLS Lift System.

Scissor Gate

Scissor gates are a very economical option and one of the oldest used for this purpose. They leave fairly large openings that allow for extremities to extend outside the confines of the carriage and into the gaps. While the North American code permits “openwork construction” able to “reject a 3-in. diameter ball,” they do not really guard against pinching hazards, and they have been banned in numerous jurisdictions. In addition, scissor gates often do not reach the full height of the car, and their fencelike design can allow for children to climb over them while the car is in motion, while still meeting code requirements.

There are many global suppliers of this type of gate, but one North American supplier is Enterprise Elevator Products.

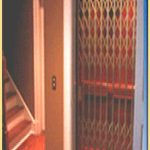

Accordion Gate

The accordion gate is likely the most common arrangement seen in private-residence elevators. The gate acts just like an accordion, with multiple panels that create alternating “V” shapes that collapse as the gate is opened. This leads to a fairly compact arrangement, and you may be familiar with these types of devices being used in architectural applications such as shopping malls to close off storefronts during nonoperational hours.

The accordion gate is one of the most economical options available, and an example of it is shown in Figure 4.

Accordion gates are often purely manually operated, but they can also be equipped with a power operator to allow for automatic operation. Two manufacturers of this type of gate are EMI Porta and Woodfold.

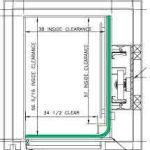

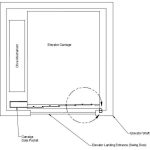

Tambour Gate

A Tambour gate is like an accordion gate. The difference is that the Tambour style wraps around in a pocket, rather than collapsing into a smaller space. This requires a curved track and space behind the cab wall within which the gate can slide. This gate takes up less space in front but more on the side than the accordion gate. An illustration is shown in Figures 5 and 6.

As you can see from the figures, the gate slides around a curved track on the elevator cab. This results in a deeper but narrower cab. This can be an advantage in some ways, but there are limitations as to how many gates can be installed in front, side and rear applications. There are also limitations on automatic operation. The Tambour type gate is flat when closed (fully covering the elevator carriage entrance) and is typically flush with the landing door due to the way it operates. This can be a substantial safety improvement compared to accordion gates.

Tambour gates are typically less expensive than full sliding door/gate sets but still more expensive than the other options.

Compact Flat Panel Gate

A new offering to the market is a derivative of the sliding gate noted above but with more panels. This arrangement takes the advantages of the accordion style in terms of compact size when fully opened but has the feel of a sliding-door set. The advantage over a sliding-door set is that the cost for this type of arrangement is similar to that of an accordion gate, and it can be operated either manually to keep costs economical or be equipped with an optional power operator in the same fashion as an accordion gate.

As will be discussed later in this article, there have been some recent code changes that have made accordion gate designs problematic, and this compact flat-panel gate has been developed specifically to meet the latest safety code changes. It is only available from one supplier, Good Gate Inc. (Figure 7).

Light Curtain Only

While there are some opinions in the industry that sufficient safety can be achieved without a physical barrier in place (for instance, the use of a photoelectrical light-curtain sensor), A17.1/B44 Section 5.3 did not allow for this arrangement at the time of this writing. The light-curtain-only arrangement is also typically less expensive than any of the above options. There are some instances where people want to consider not using a carriage gate for cases where there is a mobility/accessibility challenge, rather than for purely cost reasons. This often leads to a case where a choice needs to be made between an accessibility lift and a private-residence elevator. The codes for accessibility lifts are ASME A18.1 and CSA B355, but a full exploration of those devices and their nuanced differences from elevators is beyond the scope of this article. Figure 8 shows a light curtain on an elevator without a carriage gate.

In other instances, the homeowner does not want to open and close a manual carriage gate every time they enter and exit the elevator carriage. There are solutions for putting power operators on carriage gates, but they can result in a substantial expense increase, and economic pressure may push some to bend under customer pressure. Suffice it to say, there is no safety code acceptance for photoelectrical light-curtain-only instances, and using such an arrangement will open the manufacturer, distributor, installer and any business undertaking maintenance to significant liability.

There are pros and cons for each of these options, and, while this article wants to make you aware of them, it will not go through a complete pro-and-con assessment between each pair, but simply state that there are options available and move on to the issues that may inform your choices, as well as the safety-code changes that have recently come into play.

History of Issues

Even with a focus on safety (and ruling out the observed non-code-compliant options), there have been some significant issues related to the area around a carriage gate and landing doors. Likely, the highest-profile issue relates to a trapping hazard, with the space between the back of a landing door and front face of a carriage still sufficient to allow a small child to stand in the gap. When the elevator was called, it caused significant injury to the child. An image of the scenario that was part of a significant lawsuit is shown in Figure 9, and a video reenactment is at youtu.be/oGoPof0BytA. A full article on this tragic accident can be found at the Fair Warning site (www.fairwarning.org/2013/12/elevator).

While this case would cause virtually anyone to feel for the child, his parents and anyone associated with the family, it is also a major source of liability for anyone involved in the manufacture, distribution, installation and maintenance of private-residence elevator products.

This incident, as well as others, and the resulting lawsuit has caused some much-needed change in the industry. There was a substantial lag in the creation of new code. While the safety code was evolving, some businesses and trade professionals were adopting new practices above and beyond the code requirements. The first example of this is that some manufacturers started adding light curtains, in addition to a carriage gate, as a standard practice. This was not a code requirement but did start to address the concerns and risks associated with the incident. The second example is that some installation companies and maintenance companies started to develop a “baffle” arrangement that could be applied to the back of landing doors to reduce the space available (Figure 10).

Safety Code Evolution

Safety codes, like any other governance and regulation, evolve over time, and the elevator code is no exception. An abbreviated history of the U.S. code follows.

1955: The first safety code for private residence elevators was created by the American Society of Mechanical Engineers (ASME). It was, among other things, responding to what was, by then, the well-known problem of excess clearance that could allow small children to be present between the door and elevator carriage during operation. The code called for clearance between the hoistway doors and hoistway edge of the landing sill to not exceed 2 in., and the distance between the hoistway face of the landing door or gate and the carriage gate to not exceed 4 in.

1981: The standard was revised to allow for 5 in. of clearance and 3 in. from the back of the door to the inside of the shaft. The gap got wider as manufacturers transitioned from flat scissor gates to accordion gates. The clearance between the back of the hoistway door and the peak of the accordion could be 5 in., but the space could be as much as 7-1/2 in. or more in the valleys of the accordion, depending on how “tight” the panels were stretched in the closed position.

2016: The 3-in. X 5-in. rule was in place for A17.1/B44 until changes published on November 20, 2016, went into effect on May 20, 2017.

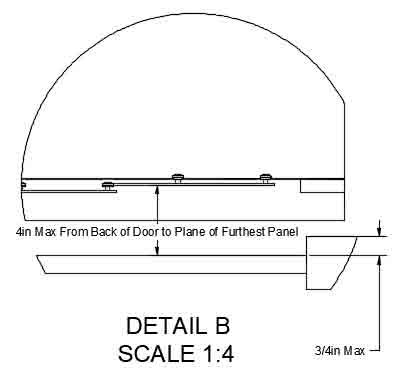

Though several changes have been made, one impacts the industry significantly when it comes to private-residence elevators. That is the change related to private-residence elevator gates and landing entrance doors. This code change requires gates to deflect no more than 3/4 in. with 75 lb. applied. The previous 3-in. X 5-in. rule for distance from the hoistway door to the sill and car gate, respectively, has been reduced to 3/4 in. X 4 in. These changes are contained in A17.1 Sections 5.3.1.7.2, 5.3.1.8.2 and 5.3.1.8.3. This means hoistway doors must be installed in such a way to ensure the back side of the door is a maximum of 3/4 in. away from the interior shaft wall and a maximum of 4 in. from the furthest point away on the carriage gate. Figures 11 and 12 highlight where the measurements are taken from for clarity.

This 3/4-in. measurement from the back face of the landing door can be difficult to achieve with a commercial swing door that is available at a home-improvement store or typical carpentry supply outlets. In many cases, a certified elevator swing door is more practical and less prone to errors. An example of this kind of door, complete with a frame, is shown in Figure 13.

It should be noted that code adoption is not automatic. Any jurisdiction (whether city, county, province or state) may adopt any version of A17.1. Many jurisdictions are decades behind: for example, some use the 2004 or older versions, even though there have been many subsequent versions. Whether a jurisdiction has adopted the code, it should be noted that complying with code is not always sufficient to protect a business from litigation, and, in cases where a child is injured, the odds are not in your favor for justifying your actions based on an old revision of the safety code.

Designing for the New Code

The first change, regarding deflection at a specified load, is significant, as it is specifically trying to ensure that a certain rigidity is in place so that a “pocket” of deflected material in a gate does not allow for a person to sandwich themselves between the back of the door and carriage gate. For a gate with too much “flexibility” (or, in engineering parlance, lower rigidity), it may meet the strict distance requirements but still create a dangerous situation that does not prohibit the presence of a trapped individual between the door and gate.

An extreme theoretical example of meeting the gap but not deflection requirements would be to use a mesh screen like what you might see on a patio door. While this type of arrangement might meet the gap requirements, it is obvious the screen is not rigid enough to really avoid the safety hazard. By codifying this, the new code has made it clear what the requirements are and hopes to avoid gate configurations that are too flexible. This deflection requirement, along with tightening the allowed space, is a significant measure to avoid dangerous situations in the entrance areas of private-residence elevators.

There are several factors that heavily influence the deflection of a gate, including physical geometry, modulus of elasticity of the main structural elements, overall moment of inertia (a result of the physical geometry), span between points of support, and load being exerted and the point at which that load is applied.

In many cases, a gate is made up of several pieces or panels. This can make the analysis exercise for a hand calculation challenging. Knowing how different materials and physical forms can impact deflection can be critical when considering requests for changes in materials, accommodating a finish request or extending a product to meet a client request (for example, an extended-height carriage). Indeed, there are many examples in product manufacturing, where small changes or extension, over time, push a design into a realm where it is no longer functioning as intended and for which it was not tested. This is often called “product drift” and can happen to even the most diligent of organizations.

Panel Deflection Calculation Example

Let’s start with a single panel that is a solid rectangle in cross-section with dimensions of 8-in.-wide X 1-1/4-in.-thick X 79-in. tall. The most common carriage height for private residences is 80 in., so using 79 in. will cover the opening and allow for some clearance. Let’s also assume the load we are trying to resist is the 75-lb load specified by the safety code.

To calculate deflection, we start by calculating the moment of inertia for the cross-section in the direction of the load applied. We will assume the load is being applied across the 1-in.-thick direction, as this is typical. The moment of inertia is calculated for a solid rectangle using the following formula:

I = 1/12 X Base X Thickness X Thickness X Thickness

In this case, base = 8 in.; thickness = 1-1/4 in.; and, for this panel geometry, the moment of inertia (I) is 1.3 in.4.

Next, we need to calculate the deflection using the following formula. Note that this formula is a reduced version of a more generic formula for general beam bending and deflection. It is used here for example purposes only to illustrate the impacts of changes. Deflection using this formula is for load applied at the midpoint of the panel span (79 in.) only.

Deflection = (F X H X H X H)/(48 X E X I)

where F = load (75 lb); H = height of the panel between support points (79 in., in this case); E = modulus of elasticity (material dependent); and I = moment of inertia (as calculated above).

Assuming the panel is solid steel for this example, the modulus of elasticity is 29,000 ksi. As a result, we get a maximum deflection at the midpoint of the panel equal to 0.02 in. This is well below the 0.75 in. required by safety code, but it is unlikely that a set of solid 1.25-in.-thick steel plates would be used as an elevator carriage gate.

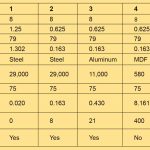

Table 2 illustrates a few key points relating to different key mechanical configuration parameters. The first parameter is that the material choice can have significant impacts due to changes in the modulus of elasticity. For instance, the modulus of elasticity for steel is 29,000 ksi, but the modulus of elasticity for aluminum is 11,000 ksi. For the commonly used medium-density-fiber (MDF) board or an acrylic sheet, the modulus of elasticity is approximately 580 ksi.

The second parameter of note is potential changes in the shape of the panel. Any change to the thickness in the direction of load will be nonlinear. This is shown in the formula where the thickness is multiplied three times (cubed). So, as shown in Table 2, if we keep all other parameters the same but make the panel half as thick, we will see a change in the moment of inertia and resultant deflection by a factor of eight.

The last parameter is to note the nonlinear nature of changes in height as they relate to deflection. This, again, is a cubic function of the height of the panel, as seen in the deflection equation. So, as seen in the table, if you increase the height of the elevator carriage a small amount, this can have significant impacts on the amount of deflection you will observe.

We have not covered the stress and failure of the materials in this article. Those, too, are considerations in the design of any product but are outside this article’s scope. For any product design, enlist the services of a qualified engineer and use testing to confirm calculations.

Conclusions

While there have been serious safety issues and concerns for this aspect of the private-residence elevator trade, the safety code we follow has recently taken significant steps forward. These changes should be welcomed, and, indeed, products that ensure the safety of the owners and users of these devices exist. However, we in the profession and supplier base need to stay vigilant, and, even if the safety code is not keeping up, we should consider the impacts to people and our own integrity as professionals when evaluating which practices to engage. In closing, from a moral perspective, if an elevator is going to be installed, don’t we all, as an industry and as humans, want it to be a safe one?

Learning-Reinforcement Questions

Use the below learning-reinforcement questions to study for the Continuing Education Assessment

Exam available online at www.elevatorbooks.com or on p. 135 of this issue.

♦ What are the main updates to the safety code related to elevator carriage gates for private residences?

♦ What are the main historical points on when the code related to carriage gates in private residences was established and changed?

♦ What are the risks associated with excess gaps/clearance between a swing door and a carriage gate?

♦ Why is the deflection of a gate an important addition to the safety code for carriage gates?

♦ What are some of the main options that exist in the marketplace, and how do they meet the revised code?

- Figure 1: Automated welding robot with safety cage; photo courtesy of WireCrafters

- Figure 2: Victory residential elevator sliding door and gate; photo courtesy of OLS Lift System.

- Figure 3: Scissor gate; photo courtesy of Bella Elevator, LLC

- Figure 4: Accordion carriage gate; photo courtesy of Atlantic Elevator

- Figure 5: Top plan view of a Tambour gate; drawing courtesy of ACME Home Elevator

- Figure 6: Isometric view of a Tambour gate on a carriage; photo courtesy of ACME Home Elevator

- Figure 7: Compact sliding panel gate; photo courtesy of Good Gate Inc.

- Figure 8: Light-curtain representation

- Figure 9: Representation of child trapped between door and accordion carriage gate; graphic courtesy of Fair Warning

- Figure 10: Door baffle; photo courtesy of www. DoorBaffles.com

- Figure 11: Topsectional vie

- Figure 12: Detailedview of door and gate for 3/4-in. X 4-in.measurements

- Figure 13: Elevator swing door with interlock; photo courtesy of Niagara Belco Ltd.

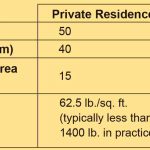

- Table-1

- Table-2

References

[1] Safety Research and Strategies Inc. (www.safetyresearch.net/blog/articles/elevator-design-hazard-’s-been-killing-children-decades).

[2] U.S. Consumer Product Safety Commission (www.cpsc.gov/s3fs-public/pdfs/Petition-CP-15-1-Residential-Elevators.pdf).

[3] Fair Warning (www.fairwarning.com).

[4] ACME Home Elevator (www.acmehe.com).

[5] T.L. Shield and Associates (www.tlshield.com).

[6] ASME A17.1/CSA B44–2016 Safety Code for Elevators and Escalators.

[7] Good Gate Inc. (www.goodgate.ca).

Get more of Elevator World. Sign up for our free e-newsletter.