A comparative study on Chinese and American elevator law

by Bin Zhao, Yuandong Jiang, Jianfeng Sun, Wei Cui and Yihui Ruan

Research Background

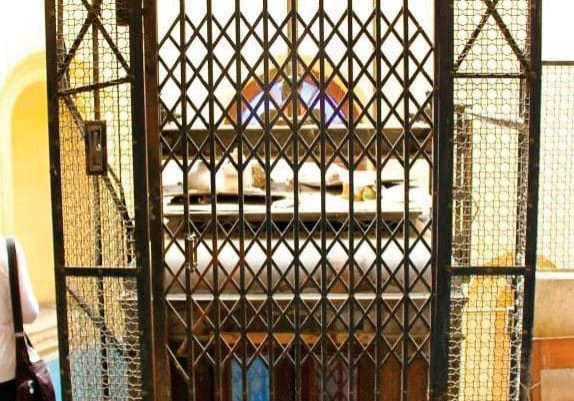

China’s economy has developed rapidly since the country adopted political reform with an opening-up policy in late 1978. Its installation of special equipment, especially elevators, grew significantly. By the end of 2012, the number of elevators in China reached nearly 2.45 million. Though the Chinese government places a high value on elevator safety and makes great efforts to develop related rules, serious accidents on elevators and escalators still happen in the country. Your authors believe the present rules on special equipment are not suitable for social development. Specific problems are:

- Users’ responsibility for safety is not explicit.

- Civil liabilities related to special equipment should be regulated.

- More serious punishment for illegal activities is needed.

China had no elevator laws until the Special Equipment Safety Law of the People’s Republic of China was passed in June 2013 and implemented on January 1, 2014. This law is divided into seven parts and applies to the production (including design, manufacture, installation, alteration and repair); sale; lease; use; testing; inspection; supervision; emergency rescue; investigation; disposal; and legal liability of special equipment.

Main Differences between China and U.S. Elevator Codes

There are some highlights in this law that are quite different from its U.S. counterpart. Main differences are:

- The Chinese law clarifies that enterprises producing, selling, operating, using and testing special equipment take legal responsibility for its safety. The local Bureau of Quality and Technical Supervision and General Administration of Quality Supervision, Inspection and Quarantine is responsible for supervision and management. Currently, special equipment is to be inspected only by the local Special Equipment Inspection and Research Institute.

In the U.S., different states have different laws and rules, as well as administrative departments. The relevant administrative department refers to Department of Labor and Industry, Office of the State Fire Marshal, Department of Labor, Licensing and Regulation, Department of Industrial Relations, and so on. Elevator inspection is implemented by inspectors from different sectors, such as government, inspection companies and insurance companies. The elevator users have the right to select them.

- In China, elevator users must be supplied with an elevator administrator(s) and corresponding operator(s) who shall be qualified and approved by the local Bureau of Quality and Technical Supervision. Manufacturers, sales and lease units must be supplied with special equipment tester(s) and operator(s). There is no such requirement in U.S. law.

- Elevator installation, modification and repair must be done by the elevator manufacturing company or its authorized permitted company in accordance with Chinese law. The elevator manufacturer may entrust other companies to perform elevator installation, alteration and repair; provide safety guidance during installation, modification, repair and monitoring; and remain in accordance with other technical safety requirements for such aspects as checking and debugging. The elevator manufacturer is responsible for the elevator safety performance. There is no such requirement in U.S. law.

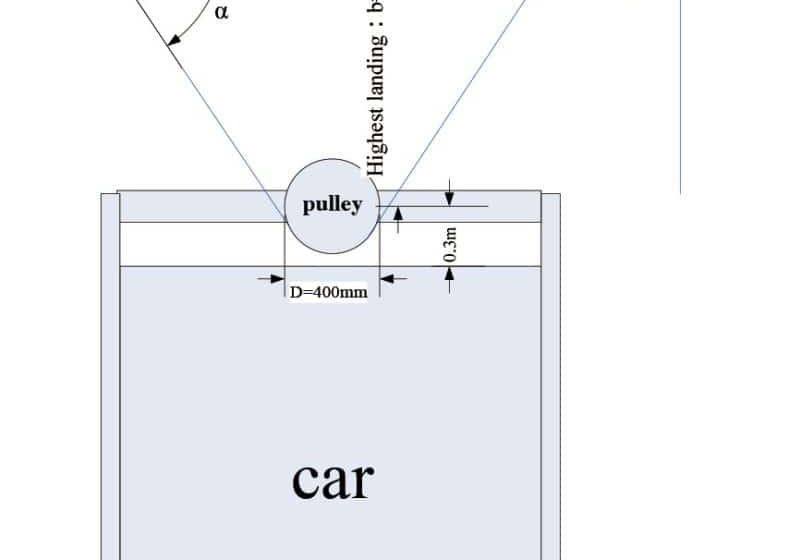

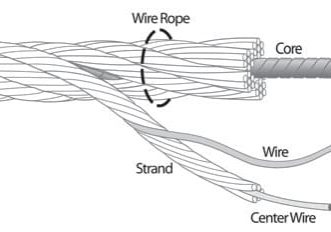

- According to China’s law, producers, sellers and users of special equipment shall obtain state-issued licenses and certifications. It also clarifies compulsory implementation of China’s latest technological safety standards and codes, which are also applicable to imported special equipment. For example, in China, elevators shall meet Regulation for Lift Supervisory Inspection and Periodical Inspection-Traction and Positive Drive Lift (TSG T7001-2009) and Safety Rules for the Construction and Installation of Electric Lifts (GB 7588-2003), and escalators and moving walks shall meet Regulation for Lift Supervisory Inspection and Periodical Inspection-Escalators and Moving Walks (TSG T7005-2009) and Safety Rules for the Construction and Installation of Escalators and Moving Walks (GB 16899-2011). It is necessary for the sellers to supply design documents; guidance for installation, usage and maintenance; a report of supervisory inspection; and other documentation. The elevator inspection report originates from the Regulations for Lift Supervisory Inspection and Periodical Inspection, which, like the other standards listed here, is uniform in China.

- In the U.S., different AHJs require different elevator codes, which often consist of some variation of ASME A17, A18, A90 and B20 standards. AHJs have the right to select older or the latest version of the standards. The elevator inspection report from one AHJ is often quite different from that of another.

- In China, manufacturers shall supply users with the related elevator technical documents and attach a date plate, warning signs and elevator usage instructions in a conspicuous location. Imported special equipment, including elevators, shall not only meet China’s related standards and technical codes for safety, but also include a date plate, warning signs and elevator usage instructions in Chinese. The departments and persons who import special equipment from abroad shall report local Bureau of Quality and Technical Supervision. There is no such requirement in U.S. law.

- In China, after an inspection is accepted, the elevator shall be inspected every year and certified before being put into operation.

- In most U.S. AHJs, annual inspection shall be performed. In some jurisdictions, however, the elevator shall be inspected twice a year or, more rarely, every other year.

- In China, when the elevator is put into use, elevator manufacturers should make a follow-up survey. If there are some problems on maintenance and safe operation, elevator manufacturers should give improvement advice to the user and maintainer and offer help. When an inspection reveals an unsafe and serious condition, elevator users and the local Bureau of Quality and Technical Supervision should be notified at once. There is no such requirement in U.S. law.

The countries can learn from each other’s strong points and raise the safety level of their vertical-transportation equipment together.

Conclusion

According to the Chinese Special Equipment Safety Law and the various American Society of Mechanical Engineers (ASME) codes, there are many differences between China and the U.S. The countries can learn from each other’s strong points and raise the safety level of their vertical-transportation equipment together. There is no doubt the laws on our industry’s equipment are of the greatest significance to its safety in both nations.

Get more of Elevator World. Sign up for our free e-newsletter.