Closing the Gap

Oct 6, 2022

Whether it involves training, changing equipment or — most importantly, safety — software company Helios is there to help.

As a third-generation elevator man, Adam Braman derives satisfaction from playing a part in making sure vertical-transportation (VT) industry workers get home safely to their families each day. Braman is CEO of NYC-based Helios, a company that has evolved in the past 11 years from a provider of software focused on efficiency, transparency and accuracy to one increasingly focused on safety. He runs the company with Chief Technology Officer (CTO) Daniel Vernis, with whom he had worked in the financial and elevator industries on and off for approximately 10 years before launching Helios in 2011. In NYC, when Braman was a manager at what was then ThyssenKrupp Elevator America, he worked with Vernis to tackle some of the OEM’s most pressing NYC challenges: inspections and a large, marquee residential job. The pair being involved in both projects brought transparency to the process and removed the paper tracking without increasing the workforce.

While attending a VT consultants event in Florida a few years prior to that with late ELEVATOR WORLD Editor Bob Caporale, Braman and Vernis got into a discussion with him about how to introduce software products to the VT industry without disrupting operations. “While spending an afternoon at EPCOT, we stumbled upon a conversation about safety and how it is the most important aspect of the industry,” Braman said. While Helios was already tracking safety of elevators, it sought to provide visibility into the safety of mechanics themselves. Thus, “Toolbox Talks” was born. Braman said:

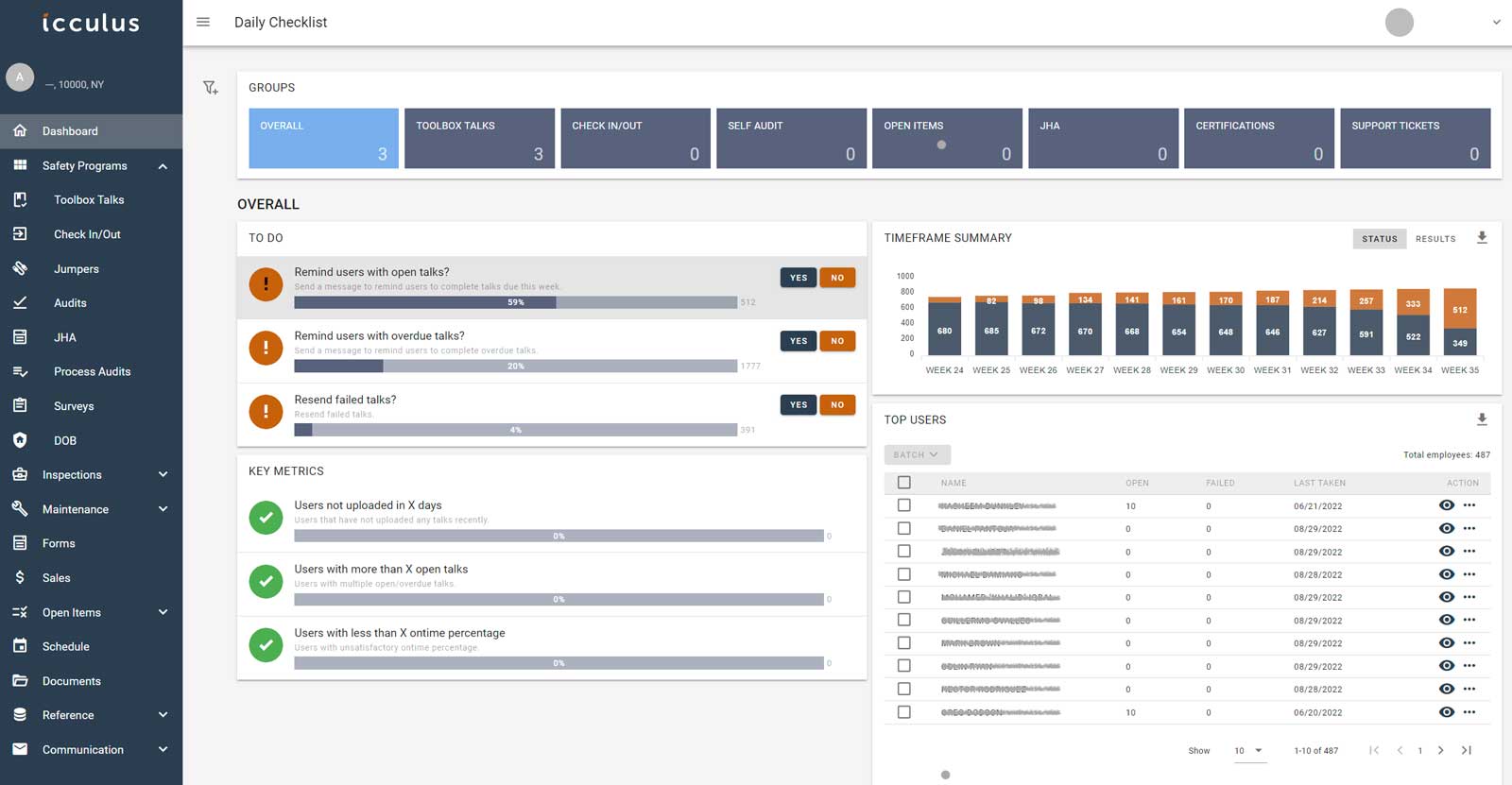

“While a small part of a safety program, [Toolbox Talks] was integral to ensuring the staff always has an eye on safety. This process has always been time-consuming from a paperwork point of view. We thought if we could provide a way to track the completion of these talks through a mobile app, it would save time collecting, collating and filing paperwork. But that was not good enough: We also wanted to know if employees had absorbed the content. So, we decided to work together to create questions to be answered with each talk. Now, we could identify not only who needed to complete the readings, but to whom and where we might need to provide additional training. This became an immediate success.”

Braman says Helios wants to ensure that every company and employee has access to the best safety program available, whether it has one employee or thousands. “Nobody should be denied proper safety training,” he says. As Helios continues to forge new partnerships and grow, Braman (AB) took the time to speak with your author (KW) about the company’s journey so far and its future.

KW: Tell me about your backgrounds and how Helios began.

AB: My background includes extensive experience in workplace efficiency regarding both workflow and financial awareness. This included introducing software to increase transparency into business functions while minimizing associated expenses and effort. Helios CTO Daniel Vernis has an extensive background in software development and architecture.

After a short stint back in the investment banking world, Daniel and I decided to partner on developing a software package for elevator companies of any size by creating a workflow management tool. The aim was to provide a better data-collection process in the field and office while allowing companies to maintain their unique approach to business. The initial focus was on the consulting and inspection industry, providing an end-to-end management system to handle everything from a fully functioning customer relationship management (CRM) program to scheduling, a field mobile app and tracking and filing required city paperwork. For client contacts, the CRM includes pricing management, proposals and a tracking solution for sales leads. Most importantly, the software provided follow-up and tracking of open items over time. From field mobile data collection that includes pictures all the way through to assigning work and completing a project, our priority is to control workflow to ensure efficiency and avoid duplicated effort. The primary focus was and is to adjust the process to the requirements of each client as they wanted to both perform and track inspections.

KW: How have Helios’s offerings evolved?

AB: As the core of our product evolved, we expanded our scope to begin to work with manufacturers to track projects from the initial survey through scope, manufacture and installation, managing the workflow, budgets and progress on jobs. Additionally, we began a partnership with GAL to develop the first link between a mobile device and a controller to wirelessly transmit Maintenance Control Plan (MCP) results to the controller where they could be viewed by any person with access. This process also allowed the service provider to control the MCP that was performed each month and track the MCP for their entire portfolio through our desktop application — a first in the industry. This product was launched at the GAL booth at the National Association of Elevator Contractors convention in Boston in 2014.

Through the course of the first few years of development prior to the Toolbox Talks, we went through many iterations of the application to improve both field and office interfaces to ensure they were easy to use; after all, user acceptance is key. Additionally, we created a web version of our desktop platform so clients did not need to worry about installing servers and maintaining databases. The app became cloud-based, and the mobile app evolved to allow use of every feature on both Apple and Android with a standard interface. It would work without requiring service. This process limited installation time for the app down to a few days, and user training became easy. Once installed from the App Store, users could understand their requirements almost immediately.

KW: Which geographical areas do you serve?

AB: While primarily working with the NYC market, we have strong connections with national organizations and committees.

KW: Tell me about the journey in terms of safety.

AB: Leveraging our experience with elevators, we determined that safety needed to be more encompassing. So, we came up with the concept of the SafetyIQ. We wanted to create a standard that tracked multiple aspects of safety and combined this information to create an assessment of the users, departments and even the company. To do this, we needed to expand our modules to include more aspects of safety, based on the requirements of each company. These modules needed to act dynamically based on the requirements for each type of user (mod versus maintenance versus truck driver). So, the Helios Modules were developed. They are:

- Audits – Regularly schedule tickets to track audits of safety bags, jobsites, vehicles, etc. This includes tracking items deemed “open” by acknowledging orders and handing them off to the end user.

- Check In and Check Out – Did your field staff get to work OK and did they leave OK? These are very important parts of the day. This can use GPS and even includes questions that must be answered, which, during COVID-19, was a requirement.

- Field Training – Tracks and provides quizzes for field staff on key processes and procedures like the Safety Absolutes.

- Job Hazard Assessment (JHA) – Generic and job-specific JHAs can be created in the system, tracked and provided to general contractors and ownership as required.

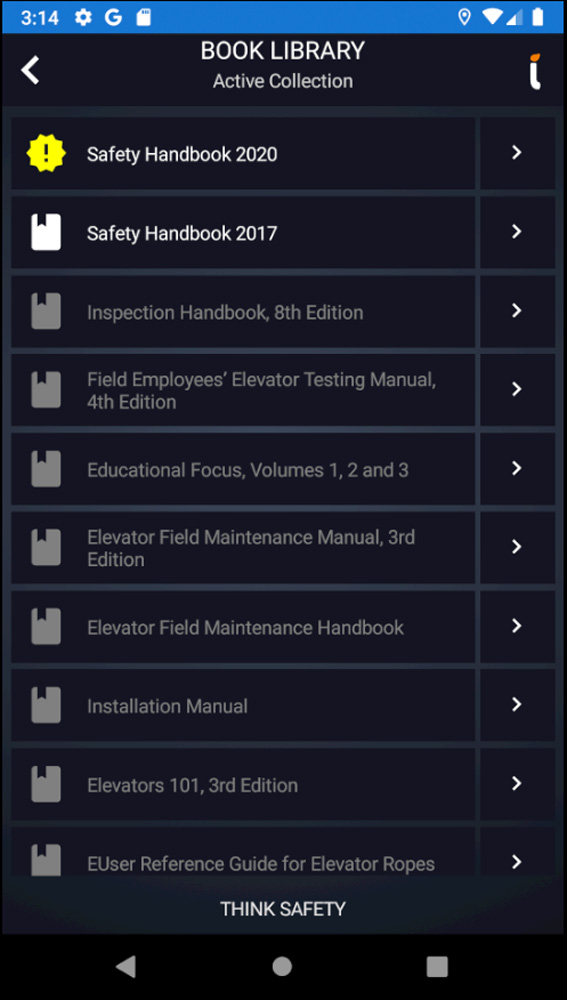

- Bookstore – We have partnered with EW to provide any book it sells, such as the Elevator Industry Field Empolyees’ Safety Handbook, on the mobile app for the field staff.

We wanted to create a standard that tracked multiple aspects of safety and combined this information to create an assessment of the users, departments and even the company.

Other modules include inspections, surveys, near misses, sales leads, hazardous conditions, MCPs and project tracking.

KW: How does Helios interact with customers to make the apps more user-friendly?

AB: One of the big questions that has come up, particularly after the [Elevator Industry Safety Summit organized by then-NAESA International Director Bob Shepherd in honor of Caporale] is, “I want to be safe and I want to follow all these great concepts for safety, but how do I track all of this efficiently?” That is where Helios comes in. Additionally, we began to partner with safety professionals in the industry who provide additional content to Helios that can be deployed at their client sites, either as a consultant to the company or an internal resource. Their content and safety program is “plug and play” with our system. Safety consultants can “train the trainer” on safety procedures and check in on progress and status by accessing the companies’ dashboards, which can make recommendations and even provide additional training.

We have multiple companies provide their records to their safety trainers to develop the content of their next training session based on the results from the Helios platform. If everyone passed confined space training, for example, you will know that you should train on another topic with higher risk across the user base.

Our messaging system, hazardous condition and near-miss tracking also began to improve so that safety professionals could analyze field data and communicate to field staff through the app. If there is a near miss, safety policy change or notification about procedures that needs to be communicated, it can be handled through the system.

KW: This sounds complicated. Has it been a challenge for users?

AB: The mobile interface is similar for each module, reducing the learning curve. On the administrative side, the website contains multiple one-click functions to remind users of open items, assign work and message with users. Each module also includes analytics for top items, top users, common tickets and other ways to identify where they need to focus. Our focus has always been that the safety manager should spend less time on paperwork and more time on training. This system allowed them to do that.

KW: How has adoption of the platform grown?

AB: Currently, the safety platform has more than 5,000 users across the U.S. and Canada, with companies ranging from one to over 800 users.

KW: What’s next for Helios?

AB: We are currently looking to partner with more organizations and safety professionals to leverage our system for their user base. We focus on the technology, and want the safety experts to provide the analysis and recommendations within their company. With safety now in the hands of the employees, we are beginning to push our other operational modules to the web platform where the learning curve is now almost zero due to a shared interface.

In addition, we can integrate safety directly into operations so you have to complete both at the same time. We have recently reintroduced:

- Maintenance Control — Creates an MCP and tracks each route/building/device, as well as what was done and the open items found, including pictures and sales leads.

- JHA — If a specific safety form is required, it is presented with each unique task. Cleaning a pit? Make sure to fill out your pit access JHA.

- Inspections — Annual, five-year and periodic inspections that include the integration of the MCP to track open items and clean up deficiencies.

- CRM — Create sales leads in the field with pictures and part requirements while tying the items to a potential duplicate in the inspection space.

- Job Tracking — A unique approach to modernization and construction tracking. This is the future of ensuring budgets and time requirements are met while providing safety integration for jobsite safety surveys, JHAs and other onsite safety requirements and reporting.

- Vendors — We are also introducing direct vendor interfaces for resupply of key items that might be required.

As mentioned with the SafetyIQ, our goal is to create a risk assessment for assets, vehicles and employees. We want companies to know where additional training or follow up may be required and use that score as a badge of honor and safety. It’s very similar to a carfax score.

KW: Where is the company physically located?

AB: Helios is formally based in NYC and now out of Vermont, with our support staff based in London and other European cities. We provide not only the system to our clients but also offer consulting services to help realize financial and workflow improvements. We also integrate with other platforms such as QuickBooks and SalesForce for additional features beyond the scope of Helios. Why replicate something when a billion dollar company has already done it and done it well?

Our plan in the immediate future is to expand to more industries under the construction and maintenance umbrella, such as electrical, plumbing and general contractors. The system was designed as “plug and play” for all content, so this pivot is quite easy. Our end state would be to see the platform become an industry standard and have the datasets leveraged to help improve the industry from training to field procedures and even tool and equipment safety.

As we mentioned, the Helios System is plug and play with content and policy provided by you or your safety professional. This also includes Elevator World, who is partnered with Helios for JHA’s, Toolbox Talks and the digital bookstore. Any book that is published by EW can be purchased and loaded on the app. Thus, providing an all-in-one safety and educational solution.

KW: What does running this company mean to you, personally?

AB: As a third-generation elevator man, it is important for me to know that we are helping everyone stay safe and get home to their families each day. This should not be looked at as, “They are tracking me,” but more along the lines of, “They are helping identify risk and, more importantly, closing the gap. . .whether it involves training, change of procedures or change of equipment and tooling.”

Get more of Elevator World. Sign up for our free e-newsletter.