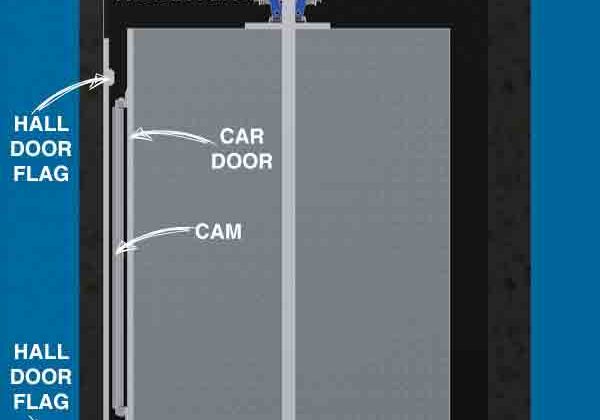

Columbia Elevator’s New Facility

Feb 1, 2012

A tour of the new Bridgeport, Connecticut, facility that opened in October 2011

by Ral

Columbia Elevator officially opened its new 170,000-sq.-ft. manufacturing and logistical distribution center in Bridgeport, Connecticut, in October 2011. The occasion was marked by a ribbon-cutting ceremony conducted by Connecticut Governor Dannel Malloy and Bridgeport Mayor Bill Finch.

Malloy commented:

“We are excited to welcome Columbia Elevator to Bridgeport. This is a [positive] situation for our state and a wonderful company like Columbia, which will grow (hopefully) to 100 employees at this site within the next five years. We’re serious about the re-industrialization of America that is going to take place over the next 10-20 years. And, here we have a great example of an outstanding company, state and city coming together, working hard toward getting this done.”

Finch framed the opening as an environmental issue:

“We know that urbanizing the U.S. is helping the environment by best developing land with high-rise buildings. We cannot do that without elevators. Elevators are the way we move vertically, on land that we develop in a high-[density] method, that has, by definition, a low carbon footprint. So, the jobs being created here are major green jobs. This is really a great day for Bridgeport.”

Columbia President Louis Blaiotta, Jr., said, “We are off to a great start here.” He also discussed how this location, in conjunction with a major OEM, enabled Columbia to manufacture all of the elevator entrances for the new World Trade Center Towers 3 and 4 in New York City. Due to the size of the new facility, Columbia is also able to add logistic coordination to its services.

Blaiotta, Jr., added:

“We are not simply fabricating our entrances and shipping them to the jobsite. Rather, we’re bringing in materials from the OEM’s factories all over the world, [combining] them with our own products, staging the job and shipping it to the site ‘on the jump,’ a few floors at a time, as needed.”

Columbia started occupying the building two years ago but could not assume ownership or operate at full capacity due to pending environmental cleanup issues.

Blaiotta, Jr. explained:

“Until all the environmental issues were resolved, reconciling what the Environmental Protection Agency wanted at the federal level and what Connecticut’s Department of Environmental Protection required at the state level, we were unable to close on the property.”

The ownership process concluded in September 2011 after three years of testing. The Remediation Action Plan was approved, allowing Connecticut to fund a grant for the cleanup. With the cleanup underway, Columbia is able to conduct manufacturing throughout the entire facility and to obtain air permits required to paint. Until now, Columbia was restricted to producing only stainless steel products that do not require painting, such as entrances and doors, and the entire operation was confined to one corner of the property, known as the “clean zone.” Anything requiring painting was made at Columbia’s Miami and Winfield, Kansas, manufacturing facilities. “Now we are able to expand into the rest of the building, operate an oven and produce baked enamel cab products in Connecticut, as well,” Blaiotta, Jr. added.

The company sees the new facility as the best way to serve its northeast customers and return to its roots, as, historically, Columbia has been a northeastern manufacturing operation. However, for the last couple of years, the facility has acted more as a distribution center with light manufacturing activity.

Louis Blaiotta, Sr., Columbia’s founder and chairman, added:

“Fifty percent of the 300 million people in this country live within 800 miles of our Bridgeport facility. We want to be where the action is, and the action is where the people are. The northeast is where we need to be, and we’re back here, bigger and better than ever.”

Get more of Elevator World. Sign up for our free e-newsletter.