Compliance and Safety: How to determine if an elevator machine guarding is OSHA compliant

Oct 2, 2023

by Pierre-Luc Bourgeois

There are several elevator equipment-guarding solutions available on the market in a wide range of prices, but why is that? Are they all equivalent? Of course not. Before going into detail about the differences, it helps to review the most common hazards found with elevator machine room equipment.

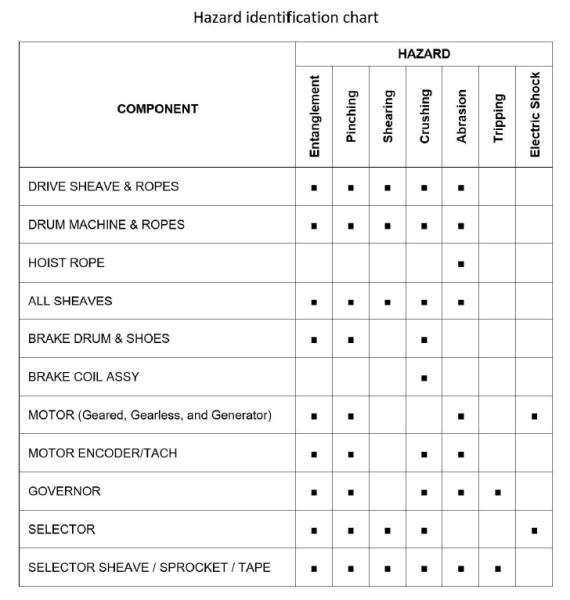

As shown in Figure 1, typical components that need to be guarded in machine rooms are governors, exposed armatures, primary and secondary brakes (arms, pads, ropes), exposed electrical and high-voltage components (commutators), primary and secondary sheaves, ropes, etc.

Rules and Regulations

Elevator machine guarding that does not protect a person from all the hazards listed in Figure 1 is not compliant with the Occupational Safety and Health Administration (OSHA) and does not fully mitigate the risk of injury or death. Governing bodies have different ways of wording their standards for guarding, but OSHA summarizes them well. Standard 1910, Subpart O – Machinery and Machine Guarding, sub-section 1910.212(a)(1) states:

“One or more methods of machine guarding shall be provided to protect the operator and other employees in the machine area from hazards such as those created by point of operation, ingoing nip points, rotating parts, flying chips and sparks.”

OSHA does not stipulate how to guard hazards, but there are standards that one can refer to. In the U.S., the standard is American National Standards Institute (ANSI) B11.19, and in Canada, it is known as Canadian Standards Association (CSA) Z432. A guarding solution must be designed as per those standards to ensure that it is OSHA compliant. Any company supplying guarding solutions should also provide a letter of compliance with their guarding. If a guarding supplier says the letter is unnecessary or does not want to provide you with one, run for your life.

How Is Compliance Determined?

How can one determine whether their guarding really is compliant? First, if you doubt it is compliant, you are probably right. There are several criteria that a guard needs to have to be OSHA compliant. We are going to simplify the standard in this article so it does not feel too heavy. Let’s have a look at the general rule for guards (excerpt from CSA Z432):

5.6.3 Apply safeguards

(i) barrier (fixed) guards or protective devices preventing exposure of any part of the body to the hazard and secured with fastener(s) that require a tool to remove.

Let’s start with the easy part.

1. Tool

Cambridge Dictionary defines “tool” as “a piece of equipment that you use with your hands to make or repair something.”

Make sure to ask what kind of tools are required to install and remove the guards, as even this basic criteria is not always met by guarding manufacturers. Make sure they do not have hand removable hardware, such as wing nuts, like several manufacturers do.

2. Safeguard

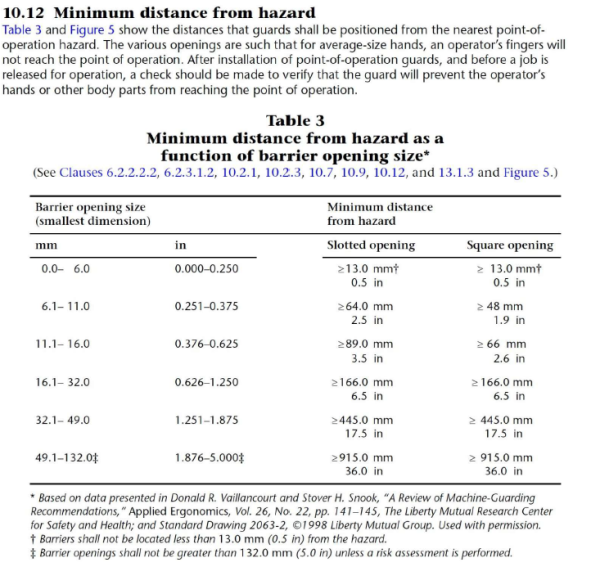

“Safeguard” is preventing exposure of any part of the body to the hazard. The keyword here is any. This part is where most elevator machine guarding manufacturers, OEM or not, fail. Sadly, it is common to see large openings to give more flexibility to guards. By trying to do something more flexible and keeping the price down, they end up failing to comply with OSHA. The ideal guard would follow the shape of the machine perfectly so no openings exist. Unfortunately, this is almost impossible to do, so a standard was created to stipulate the acceptable minimum distances from hazard. (Excerpt from CSA Z432).

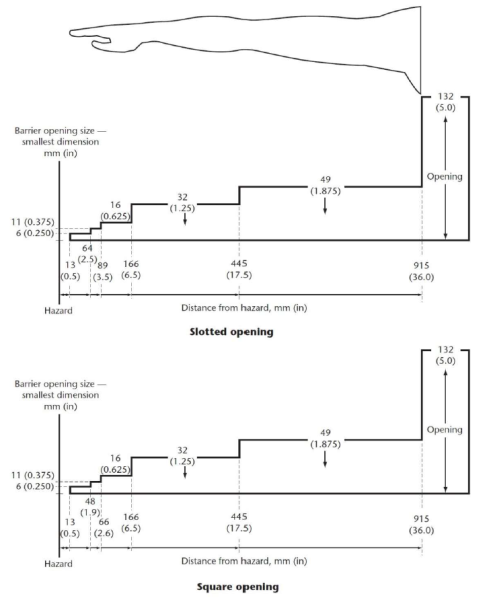

The opening sizes and safe distances in Figure 2 have been calculated based on the human body physiognomy. We can find a more visual representation of the chart in Figure 3.

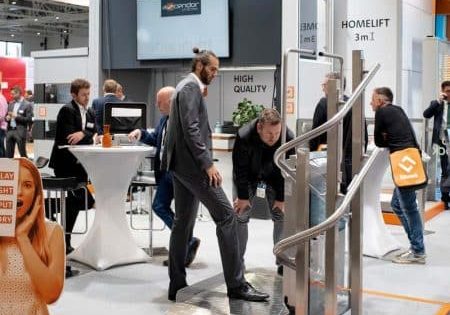

Now that we understand a bit better what the rules are and where they are from, let’s take a quick look at a few examples of non-compliant guarding solutions.

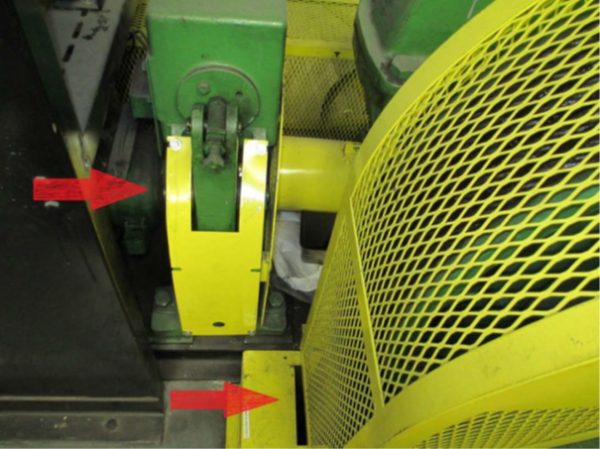

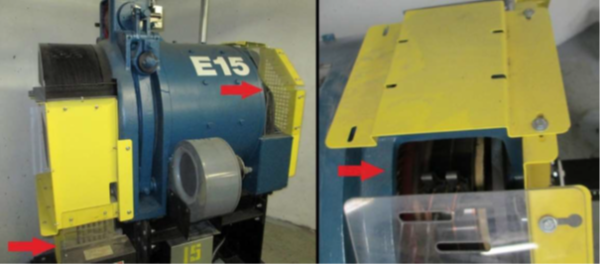

A picture is worth a thousand words so here are some examples of non-compliant guarding:

Are the guarding solutions in Images 1, 2 and 3 completely useless? Of course not, but the question one should ask themselves is why spend money on a solution that does not maximize risk mitigation? Before investing in elevator machine guarding, one should make sure that the product being purchased is compliant, as only a compliant guard will help you reduce to the maximum the risk of injury, death and liability. Giving employees a safe working environment is not only mandatory but a right we owe them.

Image 4 shows an example of an OSHA compliant guard: All hazards are covered, opening sizes are as per the table discussed earlier and guarding is secured with tool-access fasteners. The risk is then mitigated to its lowest possible value.

Type of Guarding Solutions

There are two different guarding solutions available on the market: global guarding and component guarding. Let’s discuss the pros and cons of each solution.

1. Global Guarding (also known as fencing, screen, mesh or perimeter guarding): This approach is basically a fence around the machines to separate them from each other and from controllers.

Pros:

Simple solution

Usually cheaper than component guarding, depending on size of machine and/or setup

May not need to be disassembled for major work on the machine

May be reusable if machine is modernized or replaced

Usually shorter lead-time

Minimal impact on machine visibility

Cons:

Only protects people outside the perimeter. Once inside, workers are exposed to an unguarded machine, overspeed governor and sometimes generators and tape selectors.

Cannot always be installed due to minimal clearance electrical code requirements. You need a minimum clearance of 40 in. or 1 m (USA/Canada) in front of controllers or disconnects (shut-offs). Additionally, the pathway in between the machine and the fence must be at least 18 in. or 0.46-m wide where maintenance is required.

Creates confined space between the machine and the fence, which may impact access to frequently maintained parts

Always requires room layout measurements to determine the setup, panel lengths and quantities

2. Component Guarding (also known as modular or individual guarding): This solution consists of a collection of parts assembled to guard any hazard belonging to the machine. This type of guarding is tailored to each different machine type.

Typically does not work in secondary levels

Pros:

Each component is guarded.

Access panels only expose specific machine components and keep other components guarded.

Does not require the machine to be shut off when another trade needs to work close to the machine.

Can always be installed.

Some elevator component guarding providers have standard guarding sets for common machines that can be ordered before the machine is even installed.

Light, compact and within machine footprint solution

Keeps the elevator machine room cleaner and visually more appealing.

Cons:

Usually more expensive than global guarding

Has to be tailored fit to each machine type

May need custom parts for non-standard installation setups.

May need to be disassembled for major work on the machine.

May need to be reworked if the machine is modernized and will likely need to be replaced if machine is replaced with a different machine model.

Can have a longer lead-time.

Finding component guarding manufacturers that certify the compliance of their products can be challenging.

Regardless of the machine room guarding option preferred, key questions to ask when buying and installing elevator machine guarding sets are:

Is the guarding OSHA compliant? Does the manufacturer provide letters of compliance?

Is the selected guarding solution compliant with my state/province law?

Does the guarding provide access to regularly maintained parts? Is this access good enough?

Is the guarding readily removable? Does it require more than one person to install?

Are the guards secured in place using tool-access fasteners? (Fasteners such as wing nuts are not as per code).

Will the guarding impinge on equipment operation?

Is the name of the protection kit you are about to buy called “machine guarding set”? Refer to the installation drawing of the product to find the official product name. It if says “rope guard kit” or similar, it is very unlikely that it complies with OSHA.

If you answered “no” to any of the above, it is recommended to either modify the installed guards (if possible) or find a new machine room equipment guarding supplier that will meet these criteria.

In Conclusion

Being familiar with OSHA compliance specifics will not only help you make better and safer decisions when the time comes to invest into safety, but also help increase workplace safety.

Be aware that most, if not all, of the guards sold by machine manufacturers are, unfortunately, not compliant. Getting a non-compliant manufacturer’s guard with the machine is not an optimal investment in terms of safety. It would be like driving a car without seat belts and air bags. If you have an accident, it does not mean you will be seriously injured or killed, but the likelihood of those outcomes is considerably higher without proper protection.

In this article, we have only discussed the OSHA requirements for machinery guarding. There are several other factors to consider when assessing work environment safety:

Have you identified unaddressed hazards in the workplace? (Holes in floor, beams, grease puddles, etc.). If so, how can you increase the safety at least temporarily?

Are the workers up to date on the safety practices?

Do they have the right tools?

Is there new equipment that could facilitate their work?

Question your employees about how you can make their work environment safer.

And more …

Pierre-Luc Bourgeois, P. Eng, Ing., is the director of Sales and Business Development for Flavesco Inc.

Get more of Elevator World. Sign up for our free e-newsletter.