Constructional Stretch and Hoist-Rope Tension

Jul 1, 2012

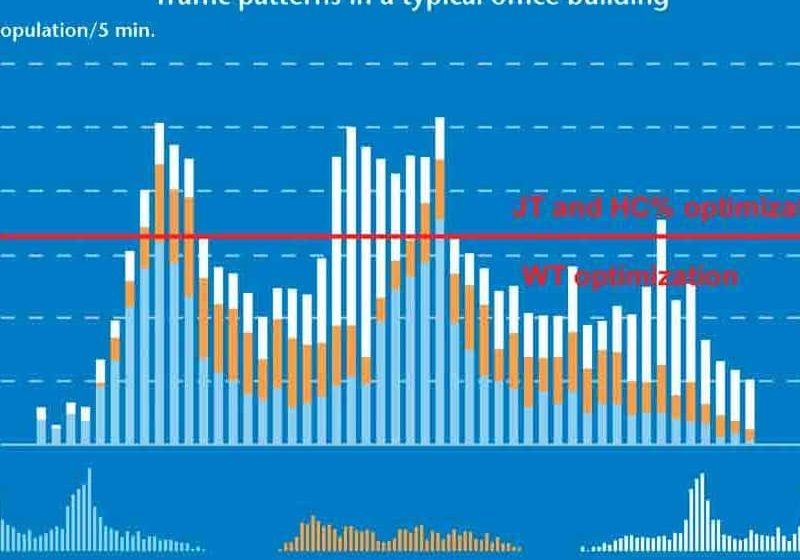

Various aspects of hoist-rope tension, stretch and measurement are examined

by Mike Barnes and Martin Rhiner

Over the years, industry professionals have sometimes chosen to avoid performing the basic maintenance routine of rope-load equalization altogether. This happens for many reasons: the prohibitive expense of having a professional crew correctly perform this tedious, exacting task; the time it requires to first adjust each rope initially, compounded with the amount of time it requires to make sure all the ropes maintain a certain degree of equalization with each other; the lack of accuracy inherent in all available tension-measurement devices; and a failure to understand how other installation components and related basic factors can impact the results of the equalization process and, in fact, make even achieving load equalization impossible.

Indeed, one of the basic factors frequently overlooked in load equalization is the constructional stretch of the ropes. Simply put, constructional stretch is the natural reaction of any helically constructed set of wires and strands in a hoist rope whenever a load is applied. Loading creates a constrictive reaction that compresses the rope’s core (bringing all elements of the rope closer and reducing the diameter), which, in turn, leads to a lengthening of the hoist rope (elongation).

Though a basic range of constructional stretch can be mathematically derived (calculated as a percentage of stretch per amount of rope length), the precise amount of stretch one can expect to encounter in a certain rope and the length of time it will take to completely stabilize the final rope length can be difficult (if not impossible) to predict. This can be attributed to the variety of ropes produced and numerous other factors, including: the type of core used; rope design; lay length; grade(s) of steel used; and the amount of pre-forming present in the rope. Other factors affecting constructional stretch include: type of installation, rope length, acceleration/deceleration, groove profile, load factors in reference to the minimum breaking load (MBL), twisting of ropes during installation and whether the ropes were equally tensioned upon installation.

Critically, however, there is no industry-wide accepted standard that mandates exactly how the ropes are to be hung. Though guidelines exist as to safety standards and what constitutes acceptable results, actual technique is open to interpretation. The entire installation/re-roping process is often driven by expediency, convenience and profitability, as much as logic and best practices. This means that when hoist ropes arrive onsite, they are seldom hung as a group simultaneously.

This inequity means not all the ropes are allowed an equal amount of time and load to stretch naturally as a group to compensate for constructional stretch. For instance, if a crew were to hang three ropes, then install the remaining ropes another day, despite even their best efforts in taking up the ropes so they all had the same length, they would find differences in rope length and tension after even a very short time. This difference can contribute to a reduction in system performance, accelerated rope wear and the eventual degradation of the sheave itself.

Brugg Wire Rope, LLC recommends an installer suspend both car and ropes, allowing time to reach and equally distribute constructional stretch, then equalize all the ropes accurately, with the provision a maintenance person will accurately equalize the ropes again three to six months later. Not only will this result in an increase in system performance (by reducing constructional stretch as a factor for consideration in rope-tension inequality), it will also allow each set of hoist ropes to attain its maximum amount of life expectancy. Additionally, such measures will reduce wear and tear on the sheave, ride quality will improve noticeably and a dramatic reduction in overall maintenance costs and breakdown incidents should be apparent.

Rope-Tensioning Measurement Devices

The most reliable, simple and efficient way to measure rope tension would be to use a tool that measures rope loads (the amount of pressure on a rope) directly. Unfortunately, most tensioning measurement devices measure loads in a rather circuitous fashion. First, one applies a certain amount of force (pressure) to deflect a host rope a certain distance, then that amount of deflection is measured. Utilizing both the amount of pressure applied and the amount of deflection measured, the device then calculates the amount of load present on the rope. Provided the user applies the device correctly, the input data derived is accurate and the formulas used in the process are implemented correctly, one might be able to collect data to be used as a basis for comparison.

A gauge to measure rope tension is both different and simpler than one that would tension the ropes themselves. When multiple hoist ropes are involved, any degree of error in the process of measurement is compounded in the final result. Even if one is dealing with accurate measurements, simply being able to ascertain loads is no guarantee of being able to use such measurements to achieve equalization. Thus, load-measurement devices can be thought of as passive indicators that reveal rope tensions without actually doing anything toward equalization.

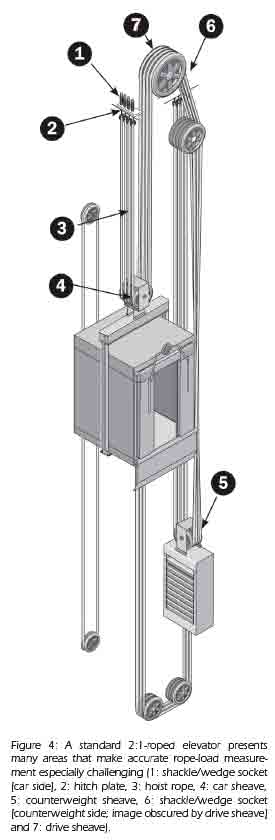

Until recently, every load-equalization method available used a tensioning measurement device in much the same way (Figure 1). Often, as many as two technicians would be involved to adjust shackle nuts, then measure rope tensions (often in more than one place, especially in 2:1 arrangements as in Figure 4), then communicate their findings so the nuts could be readjusted again. In addition to the length of time the procedure took, their difficulties were compounded by the lack of accuracy of the measurement devices themselves. It is possible the final measurement could be up to 16% off.

Some manufacturers were inclined to blame the user for any failure in achieving equalization with their tensioning device. This is possible, especially since the equalization process, when done correctly, is tedious, labor intensive and complex. This could have prompted maintenance professionals to avoid the process entirely, or, due to the inaccuracy of the measuring instrument itself, made them willing to accept something short of true rope-load equalization.

Why Tensioning-Measurement Devices Are Inaccurate

Available tensioning-measurement devices, no matter whether they use springs, wires, or a computer chip, work by applying a known quantity of force to deflect a rope. The amount of tension is then calculated after basic details such as amount of deflection, rope diameter and rope type are input. Though the form of the device may change and evolve (from plastic devices to laptop displays), the essential principle remains the same.

Unfortunately, this process relies on a few assumptions. Due to practical concerns, these devices cannot offer the user the degree of sensitivity necessary to precisely measure rope diameters, nor do they alert the user if a measurement has been taken from the peaks or valleys of a rope. This creates a degree of error in itself. These devices can only provide measurements within a certain range of precision (or, as it were, imprecision), and all measurements are taken perpendicular to the rope’s axis. This means the measurements input are not in line with the actual load itself – they are perpendicular to the direction of the load.

In addition, such devices cannot account for the many different cross sections of hoist ropes in existence. Though they limit precision, some devices utilize a simple, arbitrary factor in their calculations to allow them to quickly create readings that may be applied to fiber- or steel-core ropes in order to increase utility. Measurement devices cannot yet account for the presence of rope wear in their diameter readings, nor can they accurately factor in the impact of rope lubrication. Rope lubrication is not an insignificant factor; it affects the amount of friction within the rope’s wires, which impacts the overall accuracy of the deflection measurement.

The deflection method – inducing a bend in the rope – affects the accuracy of the results. There is even a degree of variation apparent, depending upon where the measurement is taken. For instance, due to the friction imparted between various elements in a system, tensions can slightly vary between the car and shackles, or the car and main drive sheave.

In theory, an elevator system is a balanced arrangement in which one force is perfectly countered by another. In reality, however, the movement of elevator ropes is inhibited by the many components with which they interact. Since most of the devices used to measure rope tensions state one need only measure tensions in one area of a system to acquire a satisfactory idea of rope tensions (which one then uses to tune the rope throughout an entire installation), one can see that this indirect method of measurement is, in essence, not a true scale for the accurate measurement of tensions. Instead, it is nothing more than a sampling of obtained data that, at best, can only be used to formulate a good guess of tensions.

Some argue that perfect equalization cannot be achieved. Indeed, national and international boards are still working on defining “equal tension,” and even after this is complete, decisions by such bodies will largely be confined to how the matter impacts safety. Even if experts can actually find a range of unequal rope tension they qualify as acceptable, it will be hard to verify when one is within this range due to the flaws in the measurement tool itself.

RLE Advantages

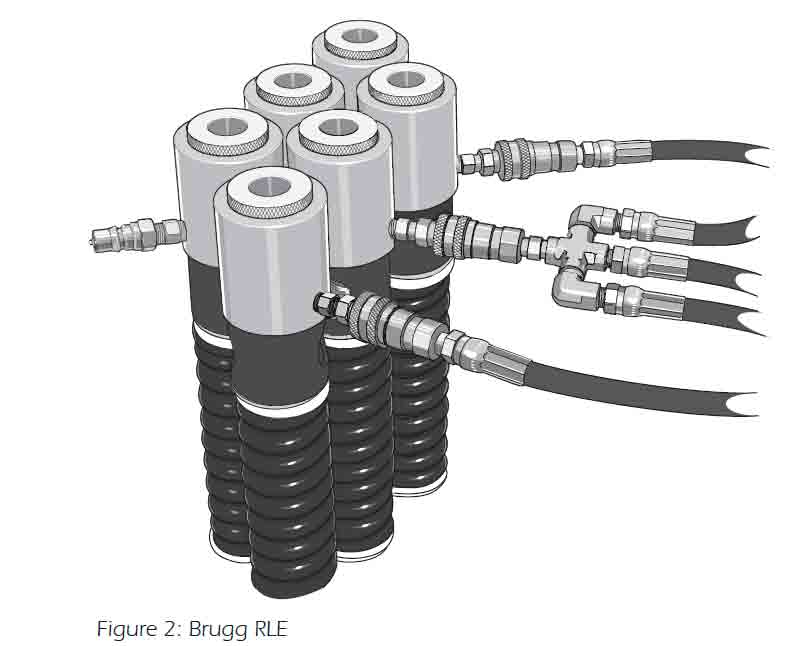

Rope-load equalization offers many advantages in ride comfort, system performance, rope-life expectancy, and sheave and component wear. Brugg’s Rope Load Equalizer (RLE) is a hydraulic device that avoids flawed measurements and hand manipulation of the ropes to attain accurate, practically automatic load equalizations (Figure 2; ELEVATOR WORLD, January 2009). Using a hydraulic fluid pumped through an interconnected system of hoses and cylinders, all the cylinders can be pressurized at the same time, which tensions all the ropes on the shackles simultaneously. This allows one person to quickly achieve rope-load equalization.

Simply put, when a fluid is introduced into a closed system, any pressure or weight when applied to one segment of a system will be distributed equally to all parts of that system. Since the RLE’s cylinders are attached to rope end terminations (Figure 4, areas 1 and 6), the pull force provided by the cylinders equalizes the tensions of all the ropes at the same time. This force is exerted directly and in line with the axis of the load carried.

Maintaining equalization requires vigilance, good maintenance technique, and, above all, equal groove depths within the drive sheave itself. Even small sheave groove variations will inevitably create different rope pitch diameters, which can quickly lead to discrepancies in rope travel distances. This can create unequal rope tensions again, leading to shortened rope life. A simple way to accurately measure groove depth within the sheave itself is by using the Brugg Groove Depth Comparator (GDC). Should groove depth variations be detected, the only effective way to maintain rope equalization may be to either re-machine or replace the sheave. Neither of these options is time or cost effective. For estimations of how long a rope will last, the Brugg Rope Life Predictor is an online program that can be used in conjunction with the RLE for accurate estimations.

Get more of Elevator World. Sign up for our free e-newsletter.