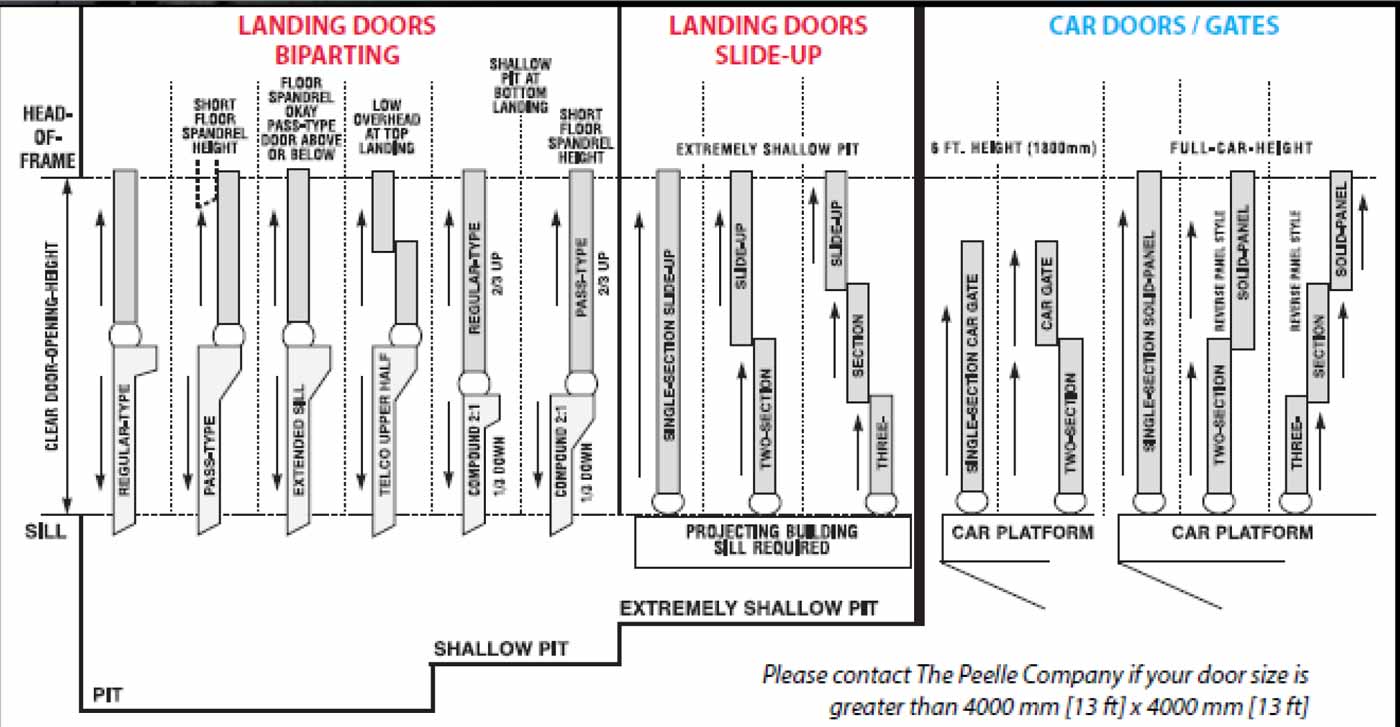

Not all freight storage and movement systems are identical, so it makes sense to match elevator doors with correct usage.

Freight elevator door designs, such as those designed and produced by Peelle, can often be described as biparting — the upper half sliding up and the lower half sliding down. Peelle describes its door as “vertical slide” to differentiate it from passenger elevator doors, which typically use horizontal slide doors.

While most elevator professionals are familiar with the biparting door, there are many variations of the vertical slide hoistway door and slide up car gate/car door, although less common which were designed to suit hoistway limitations. These hoistway limitations are physical building constraints in the form of limited floor-to-floor height, overhead height, and/or pit depth. Regardless of the hoistway limitation, when a true freight elevator with vertical slide doors is specified, Peelle’s century of experience can offer a solution from their multiple design options.

Regular Biparting Doors

A regular biparting door is the company’s standard vertical door design, and consists of an upper and a lower panel of equal height and weight. Regular biparting doors are used when there are ample floor-to-floor heights and clear overheads.

Pass and Extended Biparting Doors

Pass-type doors consist of an upper and a lower panel of equal height, with the upper panel being offset, making room for the door panel above to slide in front of or “pass” the offset panel. In this situation, the lower panel will be constructed with a wider trucking sill. This is called an extended sill. Pass-type doors are used when there are limited floor-to-floor heights.

Telco Upper Biparting Doors

Telco upper, or “telescopic upper” doors, consist of two shorter upper panels and a single lower panel. In this situation, the lower panel will be constructed with a wider trucking sill. This is called an “extended sill.” Telco uppers are used when there is minimal overhead space at the top floor.

Compound 2 to 1 Regular Biparting Doors

Compound 2 to 1 regular doors consist of a lower panel that is half the height of the upper panel. These are used at the lowest landing when there is minimal pit depth.

Compound 2 to 1 Pass and Extended Biparting Doors

Compound 2 to 1 pass and extended doors consist of a lower panel that is half the height of the upper panel, and an offset upper panel, making room for the door panel above to slide in front of, or “pass,” the offset panel. In this situation, the lower panel will be constructed with a wider trucking sill. This is called an extended sill. These are used at the lowest landing when there is minimal pit depth.

Single Section Slide-up Door

Single section slide-up doors consist of a single section panel and counterweights on either side of the door. Slide-up doors are used when there is minimal pit depth and require a building sill projection for trucking.

Two Section Slide-up Door

Two section slide-up doors consist of two equal height panels and counterweights on either side of the door. Slide-up doors are used when there is minimal pit depth and low overhead space and require a building sill projection for trucking.

Three-Section Slide-up Door

Three-section slide-up doors consist of three equal height panels and counterweights on either side of the door. Slide-up doors are used when there is minimal pit depth and low overhead space and require a building sill projection for trucking.

Single-Section Car Gates

Single-section car gates, also known as “North American style gates,” consist of a 6-ft-high single-section wire mesh panel, with chains and hangers visible from within the car. These gates are used when there is ample overhead height at the top floor, and the elevator is not rated to carry passengers.

Two-Section Car Gate

Two-section car gates, also known as “North American style gates,” consist of a 6-ft-high two-section wire mesh panel, with all chains and hangers visible from within the car. Each of the two panels are different heights. These are used when there is limited overhead space at the top floor and the elevator is not rated to carry passengers.

Single-Section Full Height Car Door

Single-section car doors, also known as “reverse panel car doors,” consist of a single section solid panel that completely covers the full opening height, with all chains and hangers inaccessible from within the car. These are used when there is ample overhead space at the top floor, and the elevator is rated to carry passengers.

Two-Section Full Height Car Door

Two-section full height car doors, also known as “reverse panel car doors,” consist of two solid panels of equal height that completely cover the full opening height, with all chains and hangers inaccessible from within the car. These are used when there is limited overhead space at the top floor, and the elevator is rated to carry passengers.

Three-Section Full Height Car Door

Three-section full height car doors, also known as “reverse panel car doors,” consist of three solid panels of equal height that completely cover the full opening height, with all chains and hangers inaccessible from within the car. These are used when there is minimal overhead space at the top floor, and the elevator is rated to carry passengers.

These Peelle vertical slide hoistway door and slide up car gate/car door options accommodate building constraints. It should be noted, however, that elevator professionals must also take other factors into consideration. When slide-up doors are provided, proper coordination with the general contractor is required for constructing an appropriate building sill projection for trucking. Typical car clearance, gate setback on the car enclosure and return space will vary based on the Peelle solution. Understanding the stakeholders’ needs will dictate the appropriate car gate/car door style. Owners and operators of freight elevators should contact their Peelle salesperson to confirm the estimated installation timeframe, noting that certain Peelle door solutions will require more installation time based on elevator installer experience and training.

Peelle is an experienced resource for appropriate door solutions and unique considerations. As soon as a hoistway design is available the Peelle engineering team can review and offer suggestions to ensure that the elevator contractor is providing the most appropriate solution for the stakeholders.

Get more of Elevator World. Sign up for our free e-newsletter.