Digitalization and Lift Doors

Jun 1, 2018

Meiller innovation makes door drives intelligent.

Digitalization is a fact of the modern world, with more and more “intelligent” devices coming into use and changing people’s lives. While its implementation has become commonplace in some areas, the adoption of these advances is proceeding at a slower pace in others. In many regards, the latter is more the case in the elevator industry.

This, however, is likely to change very soon. The industry’s major players have been focusing on this topic for a while. They have presented concepts that will soon set new standards for digital performance. As with earlier advances, smaller elevator manufacturers will once again be called upon to take action. One of the first questions to ponder is, where do components fit in with digitalization?

While this question can be answered with relative ease when it comes to standard products of a group, it becomes more complicated with special systems or products of the smaller elevator constructors. The obvious answer is that, in the future, components will network with systems, wherever possible, and generate data. The evaluation of this data provides information about the product and forms the basis for improving performance and availability and for developing new products and services that will result in new business models. Added value for operators and service companies may simply arise, for instance, when a component supplies information about status and changes. For the door manufacturer, it should be clear that the intelligence of an elevator door is located primarily in the door controller. Meiller, with its new development, the door drive concept MiDrive (MeillerintelligentDrive), is taking a first step in the direction of intelligent elevator doors.

In its new drive concept, Meiller utilizes the latest motor technology, equipped standard with a CANopen interface. Boasting high efficiency, these motors are considerably more powerful than what has been available. The range of these motors extends from 200 kg to 800 kg. In combination with these motors, it is possible to handle a very broad spectrum with almost no weight and size limitations. Meiller achieves this by means of synchronous technology, which entails the coupling of two motors with a controller to one door through to optical coupling of two drive units at landing and car doors. Doing so allows the operation of doors having a total door panel weight of up to 3.2 mT. All standard motors are offered with IP54 protection class, while special-purpose motors up to IP67 are possible. Drives for Ex Zones 1 and 2 are available.

Energy Intelligence Standards Redefined

From an energy perspective, Meiller’s new door drive concept sets innovative standards. The two energy-saving modes, ECO and ECO-Plus — which are available standard, at no extra charge, allow for switching off both the motor and the controller. Additional switches, as used in the past, are no longer necessary. Each mode achieves its savings by improving the recognition algorithms. As a result, the system uses no energy in standby mode and when the doors are closed, and correspondingly less energy during operation, thanks to the motors’ greater efficiency.

While conventional door-drive systems save energy only when idle, Meiller focuses its new door drive concept on lower energy use during the operational phase. Previously known systems are only able to thermally transform surplus energy during braking. The efficiency of Meiller’s door drive was demonstrably improved. The Meiller modern processor architecture, sophisticated energy management and operation-optimized motors work to reduce

heat loss.

The system’s energy intelligence also allows adjusting of the energy consumption of the door’s motor in relation to the outside temperature, ensuring that the motor is ready to operate even at extremely low temperatures. The dynamic assimilation of motor currents transforms the excess energy in the motor into thermal energy. The motor is heated by means of additional current supply at extremely low temperatures, and, thus, the system is kept ready to work. By comparison, current commonly used door drive systems operate with constant power, regardless of the outside temperatures, and require a separate transom heating unit for low-temperature operation.

In addition to that, the controller provides sufficient energy to actuate the electrically controlled interlocks, eliminating the need for a separate power supply.

CANopen as Standard Feature

While today’s door controllers are usually equipped with only one relay module and typically include a CANopen feature only after an extra charge, Meiller’s new door drives are designed with this communication standard built in. Consequently, the customer is free to decide if it wants to use CANopen for control purposes. Because both the controller, with its own firmware, and the controlled motors have CANopen, every additional component is able to process information and communicate with the door system.

Standard Arrangement for Fingerguard

Meiller’s new door drives will improve the FingerGuard® safety system, which protects fingers – especially the hands of young children – from being hurt in opening doors. Using sensors, the CANopen feature allows the controller to automatically suppress faults and engage the FingerGuard system. This replaces the pulse current brake with static circuit, which could only respond to signals transmitted by the sensor. For operators, CANopen means considerably smaller investments when equipping doors with this safety feature.

Servo-Assisted Mode as Standard Feature

The servo-assisted mode of the new door-drive system makes it possible to easily move heavy doors by hand, thanks to its ability to recognize and support this movement. Just as power-assist makes it easier to steer an automobile, this offers a boost when large, heavy vertical or horizontal doors must be opened manually, such as when rescuing passengers in an emergency situation.

Condition Monitoring

Data analysis is a core function of Meiller’s new door drive. Real-time data regarding usage or faults is logged in the internal memory, which can then be studied. This analysis allows for monitoring of the door drive system, which can highlight changes in the setpoint parameters and make it possible to identify potential future failures. Hardware components can be automatically identified for later updates and the status of car doors and every individual landing door can be separately recorded and analyzed.

QR Code and App

Door actuation is simple and fast via a mobile phone app. Door drives are configured onsite using defined QR codes for specific products and orders, and the door-control system can be accessed based on the order number. The lift door is assigned parameters that are adjusted to size and equipment configuration, then adapted precisely to local conditions. Product-specific settings are possible in 22 profile parameters, giving the customer perfectly adapted operating profiles and the optimum settings. This feature simplifies and speeds up start-up without requiring any essential know-how.

In case of problems, service technicians are able to quickly and easily provide support with the aid of special service QR codes. Error codes are displayed in plain language via the app on a mobile phone, making fault analysis simple for everyone.

While software updates can currently be uploaded to door controllers only via laptops, this will also be possible via mobile phones equipped with the relevant app.

Meiller’s Door Control App in Detail

The app is available for use on both Android and Apple devices, and is available in both the Apple App Store and on Google Play. The connection to the controller is implemented by Bluetooth without the user having to leave the application.

The radio link is started by using a button on the controller. After being inactive for a certain period, the link is interrupted with a corresponding message sent to the user.

The app makes start-up easy. The QR code is scanned using the the phone’s camera, which initiates data transfer to the controller and launches the teach-in operation. The system checks for firmware updates and allows the user to decide whether to initiate the update. Firmware files are downloaded to the controller from Meiller’s server.

The app also includes the appropriate operating, installation and adjustment instructions. The latest downloaded version is available for offline use. Another function is settings configuration. Through this function, data from the controller are retrieved, modified via the app and sent back to the controller. To create an external backup of specific settings, the configuration files can be sent via email and read again, if necessary.

The monitoring function makes data available to the user, such as number of door-drive cycles, motor temperature, life-cycle display of the door drive, controller type and firmware version, motor type and firmware version and warnings.

Customers can receive service and parts support through the app and, by scanning the QR code, the user can find listings for the exact part, with photo, to forward to Meiller for appropriate action.

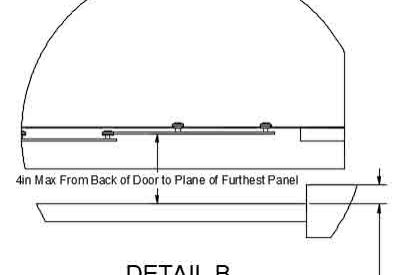

Optical Coupling of Landing and Car Doors

With Meiller’s new door drive concept, door controllers can be optically coupled so they can communicate with each other. One controller can be assigned “master” status, with other units taking the “slave” role. This alternative to the classic skate system makes it possible to “optically couple” actuated landing doors with a car door. This way, inclined lifts or horizontally moving systems can be equipped with simple, standard components. The system is particularly attractive for large and heavy freight lifts that are not equipped with skate and hook lock, or that have deficiencies that could result in movements of the car due to load displacement. The possibility of minimizing the sill gap by implementing such a concept provides leeway for other creative approaches.

With the door drive concept MiDrive, Meiller has taken the first step toward the digital world and provides the basis for future products, new services and strategic options.

Get more of Elevator World. Sign up for our free e-newsletter.