Direct-Industrial: Spares, Repairs and Onsite Support

Jan 1, 2011

Based in Blackburn, UK, Direct-Industrial is an online distributor of automation spares and repair services to the elevator industry.

by David Lenehan

Overview

Based in Blackburn, U.K., Direct-Industrial is an online distributor of automation spares and repair services to the elevator industry. In addition to offering a range of new and refurbished automation parts, the company offers a responsive fixed-price repair service, which is backed by a comprehensive 12-month warranty. The repair service offers elevator providers an alternative to purchasing new or refurbished parts and

is particularly useful for companies offering fixed-price maintenance contracts.

Background

Founded in 1978 by the current managing director, John Lenehan, the company has evolved from a one-man band to a leading online provider of automation spares and repair to the industry. Originally established as Northern Industrial Electronics, to provide electrical services to the local textile industry, it benefited from the growing use of electronics in the textile industry by investing in the high-tech testing equipment required to repair automation parts. The company quickly gained a reputation for providing quality automation repair services and attracted textile customers throughout the U.K. and mainland Europe.

As the textile industry shifted production to the Far East in the 1990s, the company started to offer its repair expertise to different market sectors including food production, CNC engineering and printing. During this period, the company became involved in the sale of refurbished automation parts over the Internet and started trading under the Direct-Industrial brand. The name change reflected the move away from being an automation repair provider to a one-stop shop for automation spares and repairs.

Although the company was involved in a wider range of industries, the elevator industry was not something it considered until a chance phone call late one Friday evening from the service manager of a major elevator manufacturer. It had an urgent lift drive failure and wanted to know if we could try to repair it. After some evaluation, we managed to adapt our test facilities to run the AC drive under test conditions and successfully repair the unit. It was the start of a long-term relationship with the elevator and escalator industry.

Since that phone call, Direct-Industrial has developed a successful niche providing a responsive automation repair service to the U.K. elevator industry. The repair service offers cost savings against purchasing new equipment and is particularly popular with elevator companies that offer fixed-price maintenance contracts. For these companies, purchasing replacement automation parts can be an unwanted expense and seriously affect the profitability of the contract. Reliability is also a key to the success of Direct-Industrial.

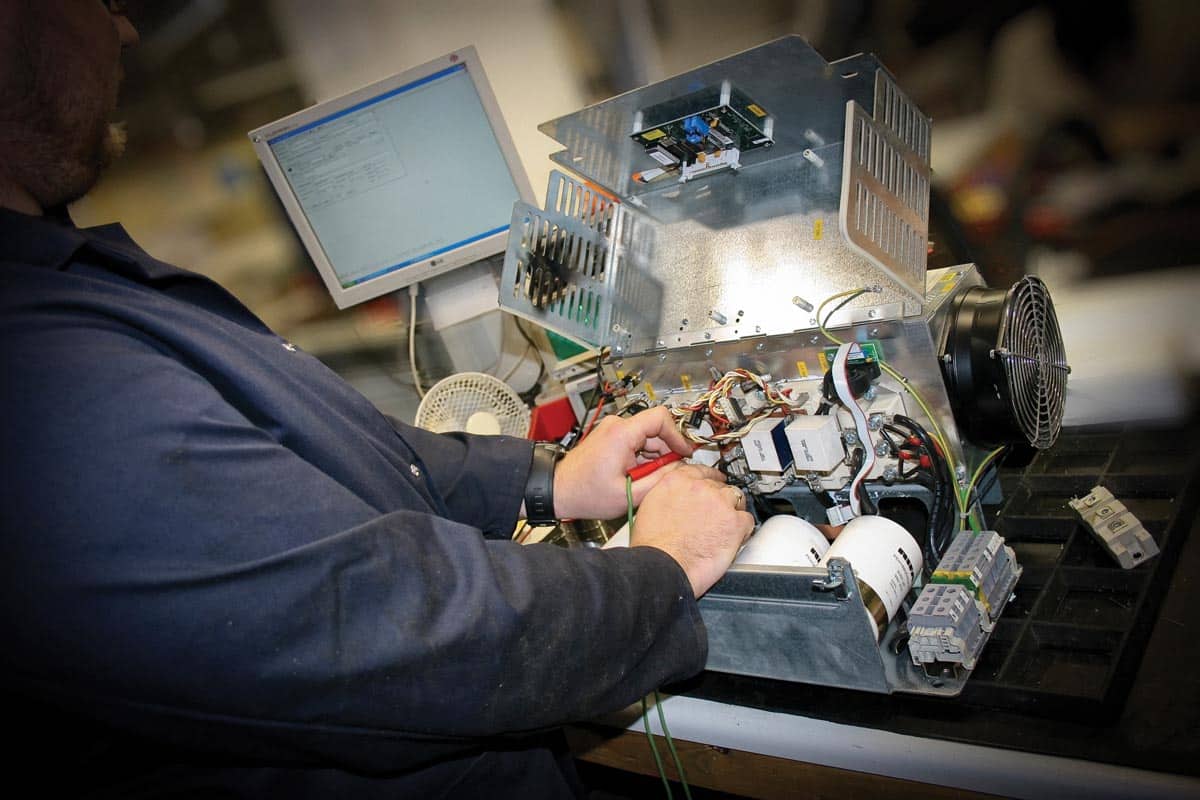

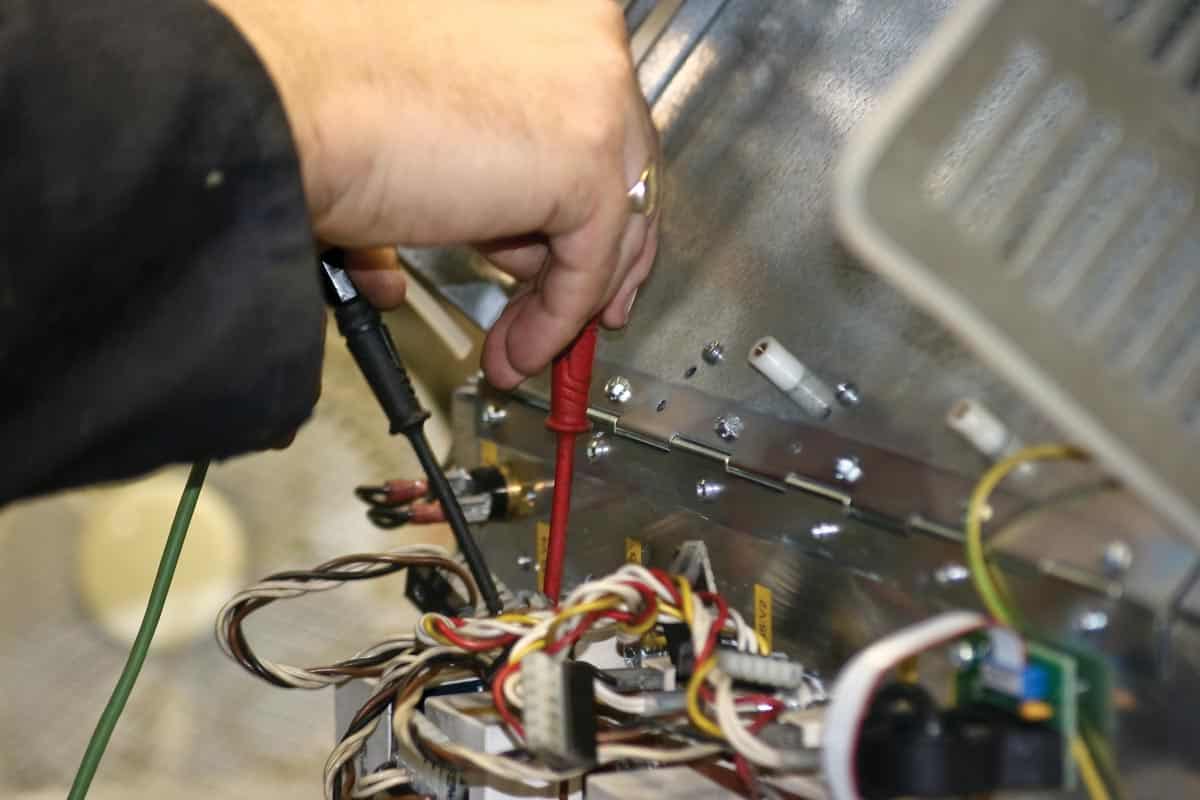

The repair facility offers the Inverter Drive test bay, which is designed to simulate real-life operating conditions of elevator drives. Using a high-voltage testing area, Direct-Industrial is able to load test the bulk of repaired AC drives under heavy load for a number of hours. This helps ensure the quality and reliability of AC drive repairs.

Prolonging the life expectancy of repaired parts rather than just curing the initial fault is always a goal and can be achieved by replacing any components likely to deteriorate and degrade with age. Many problems experienced with automation can be directly attributed to component failure through old age.

A test and repair facility helps Direct-Industrial stay ahead of the competition, with our biggest asset being our engineers. The majority are trained in electronics, and all undergo regular training on the latest automation technology and repair procedures. A good grounding

in automation technology enables our engineers to be extremely versatile and tackle repairs without documentation or wiring diagrams.

The Future

General Manager Stuart Park explains:

“Moving forward, 2011 will be a big year for the company. In order to meet customer demand, we will be moving to a new purpose-built repair facility toward the end of 2011. The new building will be three times the size of our current facility and will allow us to continue to develop into one of the world-leading automation solution providers.”

“A lot of our success has been down to word of mouth. The lift industry is very insular, with engineers regularly moving between companies. We often find it is the front-line engineers who recommend us to other engineers, who in turn recommend us to others. I think this proves we are doing something right.”

Recent Projects

As one of the U.K.’s leading venues for live music, The Sage Gateshead is accustomed to playing host to some of the biggest names in world music. Tyneside, U.K., born musician Sting was back in his home town to perform the last show in his sellout Symphonicity European tour. With as much equipment as was involved in the Symphonicity tour, even the smallest problems can become magnified. Just 24 hours before the show, the goods lift broke down. Without a working goods lift, the performers would not have been able to transport their equipment onto the stage.

The facilities manager contacted lift service provider Orona to arrange an engineer visit. Upon arriving at the site, the Orona engineer quickly traced the problem back to the elevator drive. Due to the weekend and close proximity of the show, sourcing a replacement was not a viable option. The Orona engineer therefore took decisive action and contacted Direct-Industrial to arrange an urgent repair. The drive was delivered the same day to Direct-Industrial’s automation repair facility in Blackburn, Lancashire, U.K.

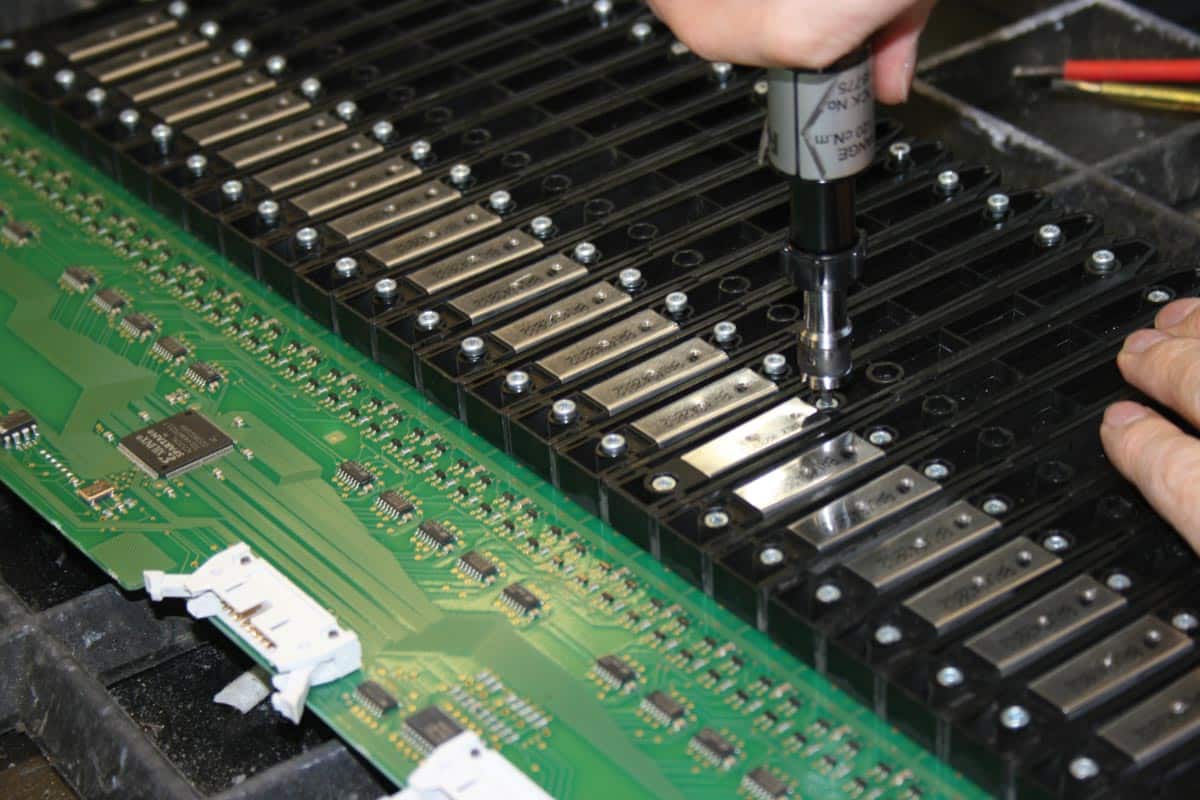

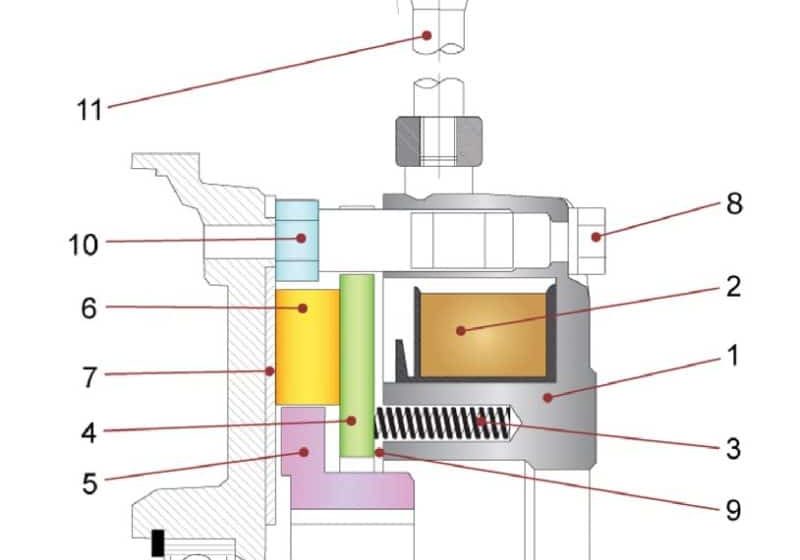

Direct-Industrial engineers worked through the night to repair and service the faulty drive. After visually inspecting the drive, the engineers removed each card and powered them individually. This enabled them to narrow down the problem to the power board. It was discovered that a fault on the firing stage was pulling down the supply rails, thereby causing the drive to malfunction.

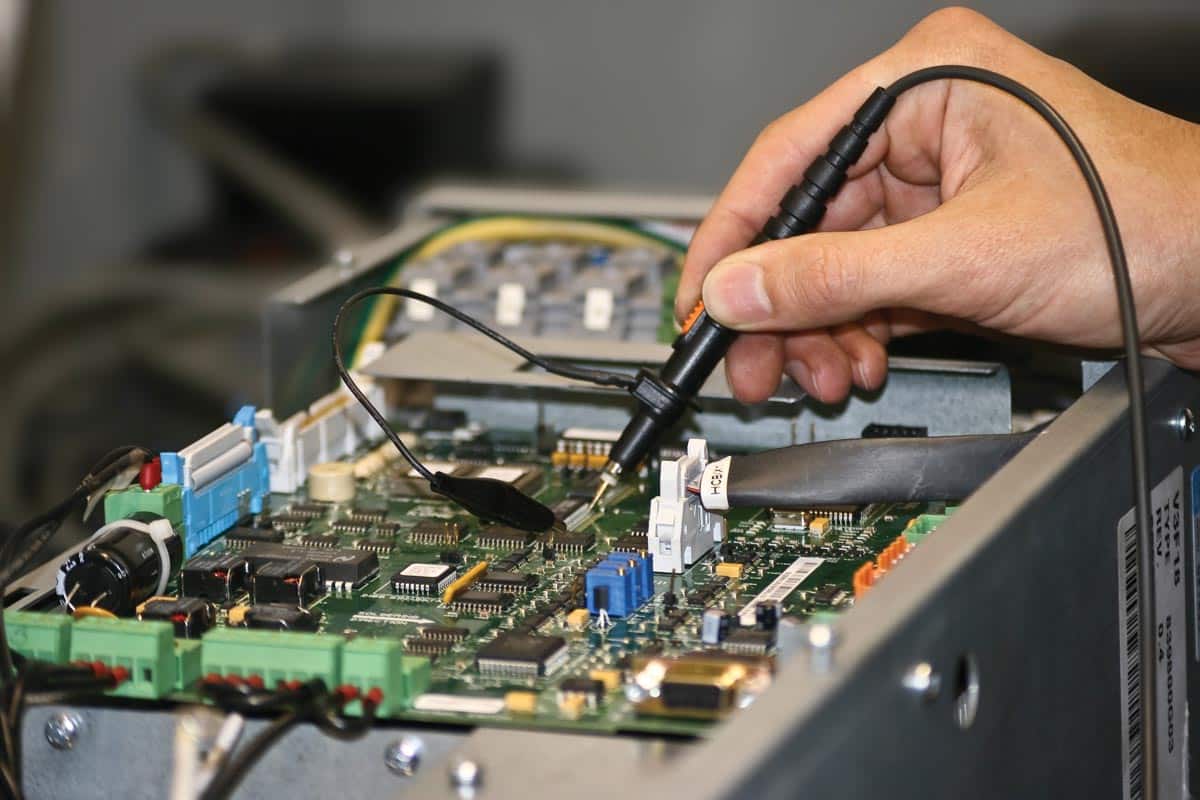

Utilizing the latest techniques in analog signature analysis, the problem was reduced to a single firing stage, after which the use of a dedicated short locating tool directed the engineer to the root cause – a short circuit capacitor. Once the fault had been fixed, the engineers performed a full preventive maintenance service on the drive by replacing serviceable parts such as capacitors, fans and relays.

A large proportion of drive problems result from component failure through old age. For example, capacitors can leak corrosive acid on the internal printed circuit board. A full service from Direct-Industrial can replace these parts and reduce the chance of drive failure and expensive downtime.

By early Saturday morning, the drive was on load test after being completely serviced and repaired and was ready to be returned, complete with a 12-month warranty. The repaired AC drive was returned the same day and fitted by an Orona engineer just hours before the show. Needless to say, the Sage Gateshead was happy with the professional and rapid response from Orona and Direct-Industrial.

Get more of Elevator World. Sign up for our free e-newsletter.