Does It Make Sense to Go Green? A Small Business Dilemma

Apr 1, 2011

Should small businesses go green and, if so, is it worth it?

by Allison C. Weber

To go or not to go green – that is the question that many small companies want to avoid. Yes, of course, we all want to be mindful of the environment, but at what cost? Is it really worth it, or is “going green” just the current trend? If so, will those small businesses taking the risk to go green be at an economic disadvantage when the next new trend replaces it, or is green the way of the future and ultimately a good business decision that will lead to having an economic edge over your competitors?

Unfortunately, there are compelling arguments for either course of action. The pros include lofty goals – showing your commitment to the planet, distinguishing your company from the competition, setting an example for employees to take home, and the hope that going green will foster innovative practices and aid in attracting and retaining talented employees. True, some studies show that the green economy is growing 10 times faster than the general economy, and big businesses are competing against each other in the race to go green. According to Forbes, even Wal-Mart admits that green products continually drive its sales growth. But what about small business?

The con list is shorter but goes straight to the bottom line. Green may be relevant, but is it feasible? It sounds nice on paper, but it will definitely cost you money up front. Can you really afford it in the present economy? Do your customers really care about anything beyond the invoice price? If you go green, are you giving your competitors the ability to underbid your prices and gain a greater market share? This article is about how one small manufacturing company made the hard decision to go green.

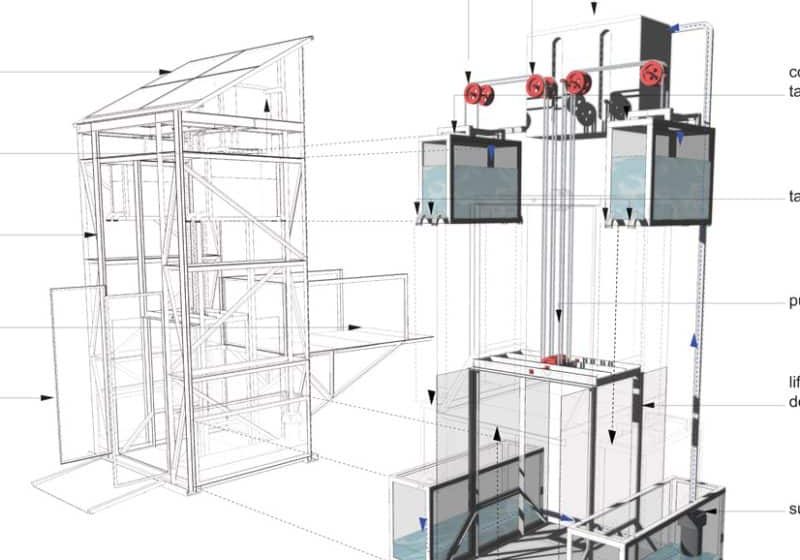

WestCoast Protective Elevator Pads (now WestCoast Innovative Pro Pads) was founded in 1983 by Leslie Malloy. Her “going green” decision-making process actually began when she was in elementary school and participated in the first “Earth Day” – April 22, 1970. This day, designated to foster awareness and appreciation for the earth’s natural environment, was a grassroots response to the recently acknowledged environmental crisis and marked the beginning of the modern environmental movement. Shortly thereafter, the word “ecology” entered our vocabulary, and over the next decade, campaigns were launched to stop littering, reduce pollution, conserve fossil fuels by driving smaller automobiles and turning down home thermostats, and recycling.

Thirteen years after the inaugural Earth Day, WestCoast began making protective elevator pads. Initially, decisions needed to be made about what type of fabric to use for the pads. The industry standard called for fiberglass-filled pads, but we desired a less synthetic product – one that was healthier for our employees to work with and better for the environment. We opted for a U.S.-grown 100% cotton fill and a 100% cotton canvas cover. Although we also produced a vinyl pad at the request of some customers, from the beginning, the vast majority of our pads was manufactured from a natural, biodegradable and renewable resource that was hypoallergenic and static free. Using cotton also takes advantage of modern cotton farming technology, which uses less land, water and energy; effects less soil erosion; and requires reduced pesticide application.

We also found that the required flame-proofing products spanned the entire environmentally conscious continuum. For example, polybrominated diphenyl ethers are common flame retardants that accumulate in dust. These compounds have recently received increased scrutiny, as studies show that they pass through breast milk fed to babies, causing a significant decrease in fertility and having an adverse effect on liver and neurological systems. This prompted us to make the greener decision by choosing Flamort CP – a clear, nontoxic, fire-retardant liquid for natural and synthetic fabrics. Despite its lack of toxicity, it has passed the National Fire Protection Association 701 vertical burn test, California State Title 19 Health and Safety Code, New York BSA CAL. #294-40SR, and the American Society for Testing and Materials E84 Class A Flame Spread Standard.

As the years went on, WestCoast consciously implemented green practices at our manufacturing plant. To thwart the southern California sunshine, the building was painted a lighter color to reflect the heat, awnings were installed over the windows and tinted film was applied to the glass. Later, solar panels went on the roof to reduce the need for electric heat, and drought-resistant landscaping was designed to save water. More recently, we have started a vigorous in-house recycling program, changed to green cleaning products and installed energy-saving light bulbs and appliances. This year, we implemented strategies to use less paper, including a paperless invoicing system.

Of course adopting all of these practices was well and good, but what about the impact on our product and its bottom line? The question constantly facing us now became, “Could we continue to be green and stay competitive?” In making our decision, we were forced to reexamine our definition of “cost” and what it means to the price our customers pay.

The California Sustainability Alliance states the case very simply: every purchase has an environmental impact resulting from the combined impact of a product’s manufacture, use and disposition. Accordingly, its goal is for consumers to include environmental considerations in purchasing decisions, along with the traditional concerns of price, performance and availability. Likewise, it encourages businesses to remain fiscally responsible, while promoting practices that improve public health and safety, reduce pollution, conserve natural resources, and reward manufacturers and vendors that reduce the adverse environmental impact of their production and distribution systems.

Against that backdrop, the alliance advises when comparing costs to calculate and compare total costs over the life of the item, which includes maintenance, initial, operating, insurance, disposal, replacement and potential liability costs. Examining lifecycle costs will save money by ensuring we are quantifying the total cost of ownership before making purchasing decisions. Competition exists not only in prices, but also in quality and performance, including environmental performance. Balancing these sometimes-competing factors means that initial cost is never the only consideration. It also means we will sometimes pay more for higher-performing goods and servicers, including those with superior environmental performance.

Admittedly, delving too deeply into the lifecycle of a protective elevator pad may verge on the ridiculous. We also know that price is often the only consideration for some of the elevator pads provided by the manufacturer to meet a specification. However, WestCoast chooses to embrace the alliance’s approach to measuring cost, because it just makes sense to us. After nearly 30 years of applying that philosophy, we are very proud to offer the industry a competitively priced green alternative. All of the raw materials that go into our pads are grown or made in the U.S. Our manufacturing is not outsourced; we produce our pads onsite in California, where we have 37 employees.

While some maintain that the pressure on companies to disclose how they are addressing environmental issues will continue to grow, none of us know if that’s really the case or what impact that pressure will actually exert beyond giant corporations. What we do know is that small firms make up 98% of all U.S. companies and, according to www.greenbiz.com, although we may individually be small resource users and waste emitters, we cumulatively are an environmental force.

WestCoast chooses to manufacture pads with superior environmental performance. We are committed to being green and have adopted a way of thinking that considers the impact of all the choices we make about running our business. However, it is anything but easy for a small business to adopt green practices. Our experience does confirm, however, that when all is said and done, the decision is easier when you believe it’s the right thing to do.

Get more of Elevator World. Sign up for our free e-newsletter.