Door Operator Technology and the Progression to Linear Drive Systems

Apr 1, 2024

In this Readers’ Platform, your author takes readers on a walk through history.

by Andrew Goodwin

The American technological revolution of 1880 to 1890 produced a wave of new inventions that helped architects build higher than ever before. Bessemer steel, formed into I-beams, enabled taller and more flexible frame design than cast iron; newly patented sprinkler heads allowed buildings to avoid strict height limits that were imposed to control the risk of fire; and the patenting of AC electricity allowed elevators to be electrically powered and rise to 10 or more stories.

The resultant increase in building height placed design pressure on the subsystems technology that compromised the entire elevator ecosystem. Machines, control systems, hoist ropes, safeties and door equipment all needed to “keep up” with the demands of taller buildings. This article will examine the history of door equipment and the evolution to today’s linear-drive technology.

How It Began

For many, the introduction of elevator systems as a new technology was intimidating. Much of the riding public was wary of riding by themselves. The solution was to provide elevator operators — personnel who were there to open and close the hoistway doors and car gates, operate the manual car switch or enter a floor call, depending on the operating system.

This was the norm for almost 50 years — until 1945 when elevator operators went on strike. Initially, there was a hesitancy to use elevators “alone.” The industry responded by installing communication systems and emergency-stop buttons. When a strike occurred again the next year, building tenants and workers had adjusted to riding alone. The age of fully automatic elevator designs — including door systems — was born.

Today’s door operators are motor driven and operate based on command logic communicated by the control system. Very simply, the door operator opens and closes the car door and, using a clutch, concurrently opens the hoistway door(s). There are two types of door operators: harmonic and linear.

Harmonic Door Operators

Harmonic door operators were the first automatic door-operating systems available. The door operators utilized geometric “4-in. bar linkages” to gain mechanical and speed control with the use of single-speed motors. To the engineer, the harmonic door operator was brilliant geometry elevated almost to an art form.

To the engineer, the harmonic door operator was brilliant geometry elevated almost to an art form.

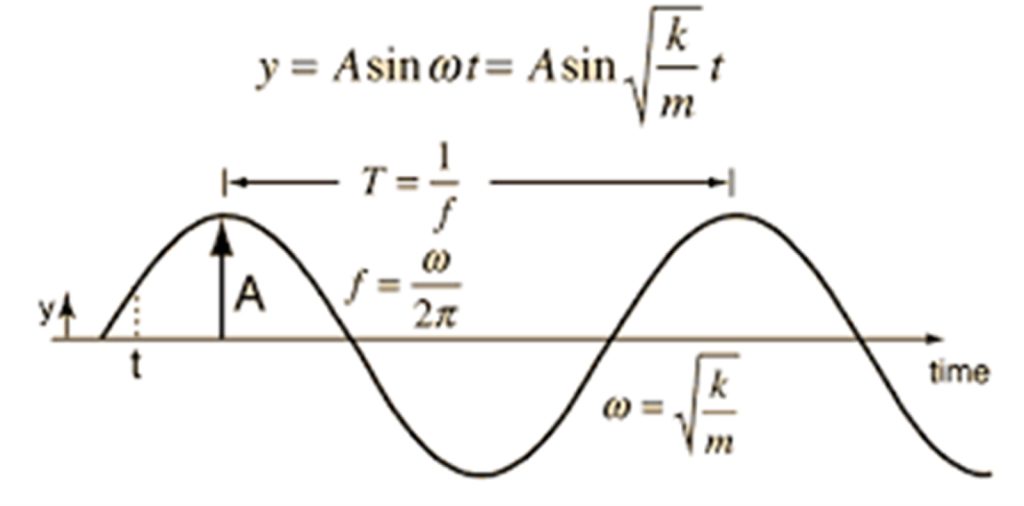

Why the term “harmonic?” Simply stated, the drive arm system creates a harmonic speed profile. This is a mechanical speed profile calculated from the geometric angles of the drive arms. Harmonics are the motion an oscillating mass experiences when the restoring force is proportional to the displacement, but in opposite directions. Harmonic motion is periodic and can be represented by a sine wave with constant frequency and amplitude. Figure 1 depicts the continuous fluid movement of a harmonic sine wave.

Linear Door Operators

Linear motion is the movement of an object in one dimension, from one place to another in a straight line. While linear motion can be vertical or horizontal, for our purposes we will consider the motion to be horizontal.

As technology progressed in the areas of hydraulics, worm/gear designs and even steam power, linear designs began to enter the market in the early 1970s. For the most part, early linear designs were not well-received due to reliability issues compared to harmonic designs and lack of sophisticated motor control.

Today, overall improvements in technology have positioned the linear door operator as the “norm” for new construction projects, leading to year-over-year increases in market share. Linear operators are typically lighter than their harmonic counterparts with fewer moving parts. The elimination of cams and linkages reduces the risk of potential maintenance issues. Precise encoder positioning, along with closed-loop software, allows for consistent performance in varying project installations. Linear operators are generally self-learning and have the ability to create a smooth “virtual” drive curve in any operating environment.

Harmonic door operators are reliable and will continue to serve the market well. However, as demands for installation efficiency, common technical platforms between new construction, modernization and repair, as well as predictive maintenance capabilities, become increasingly prevalent, the adoption of linear door operators is expected to rise.

My Favorite Operator

As the product director for door equipment at GAL, I am often asked, “What’s your favorite door operator?” I found the answer to that question last year while celebrating my grandmother’s 100th birthday. As we gathered to celebrate, spending time with her recounting stories of the past, I also shared stories of what I do in the elevator industry. At one point, she turned to me and said, “Did you know I used to be an elevator operator?” I was stunned, and the irony of my work and her past collided. I had no idea. She proceeded to tell us that, in the 1940s, she moved to NYC to pursue a modeling/acting career. As a part-time job, she was an elevator operator in Midtown Manhattan. While she couldn’t remember the name of the building or its precise location, she recounted the uniform, the white gloves and the button pushing. How special those white gloves were to her! Since hearing her story, my grandmother will always be my favorite operator!

Get more of Elevator World. Sign up for our free e-newsletter.