A look back to the turn of the 20th century reveals the rocky start of these important devices.

One of the first American elevator books was H. Robert Cullmer’s Elevator Shaft Construction (1912). This early work examined almost every aspect of elevator shaft design, including recommendations for proper guide-rail care and maintenance. Cullmer reported that “very few” people understood “the large amount of power that is lost by friction between the elevator guide shoes and guides when not properly lubricated.”[1] He described the problem as follows: “It has been and now is the general custom to lubricate the elevator guides by hand application of grease. It will be realized that by this method, a large amount of time and labor is lost, both by the man applying the grease and the operator running the car while this work is being done.”[1]

This system was, however, seen as inefficient and, quite often, ineffective: “When it is considered that some of the elevators in modern buildings travel as much as 5 mi. per day, it will be observed that this hand application of grease is not sufficient to insure economical operation.”[1] Cullmer recommended that the “economical and scientific operation” of elevators required “automatic guide lubricators.”[1] The first automatic elevator guide lubricators were developed in the late 19th century. These systems are the subject of this month’s article.

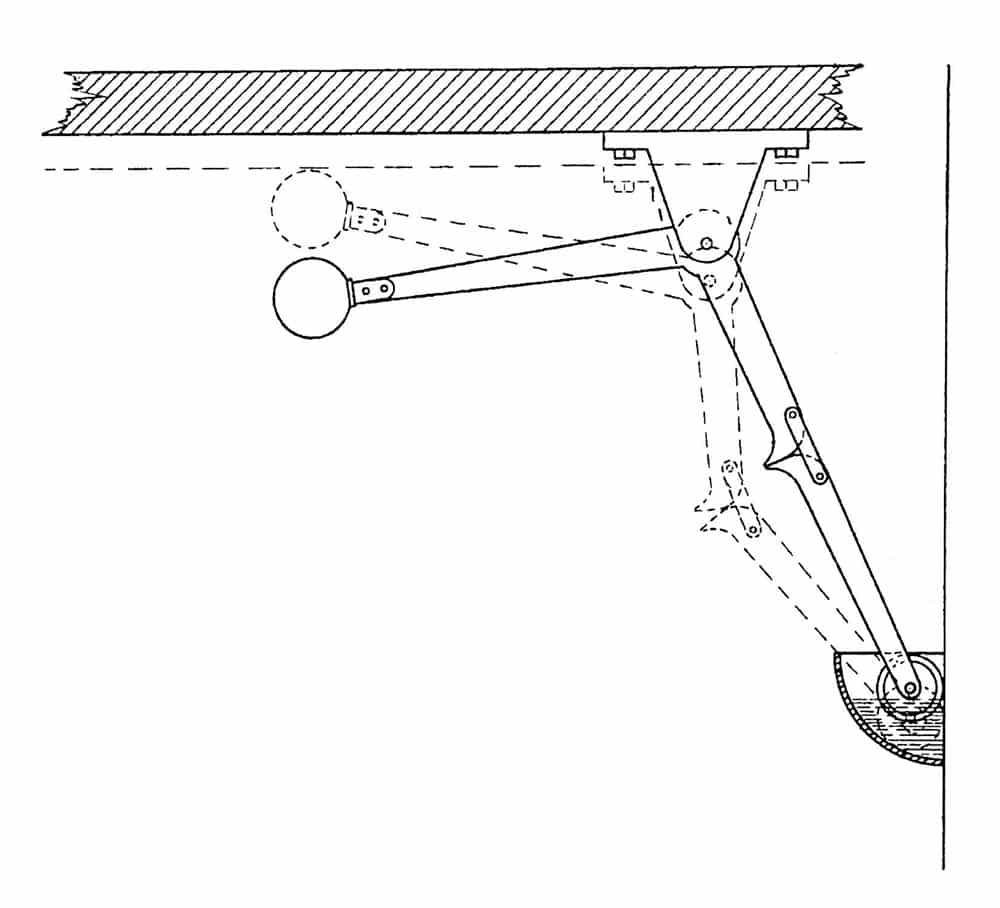

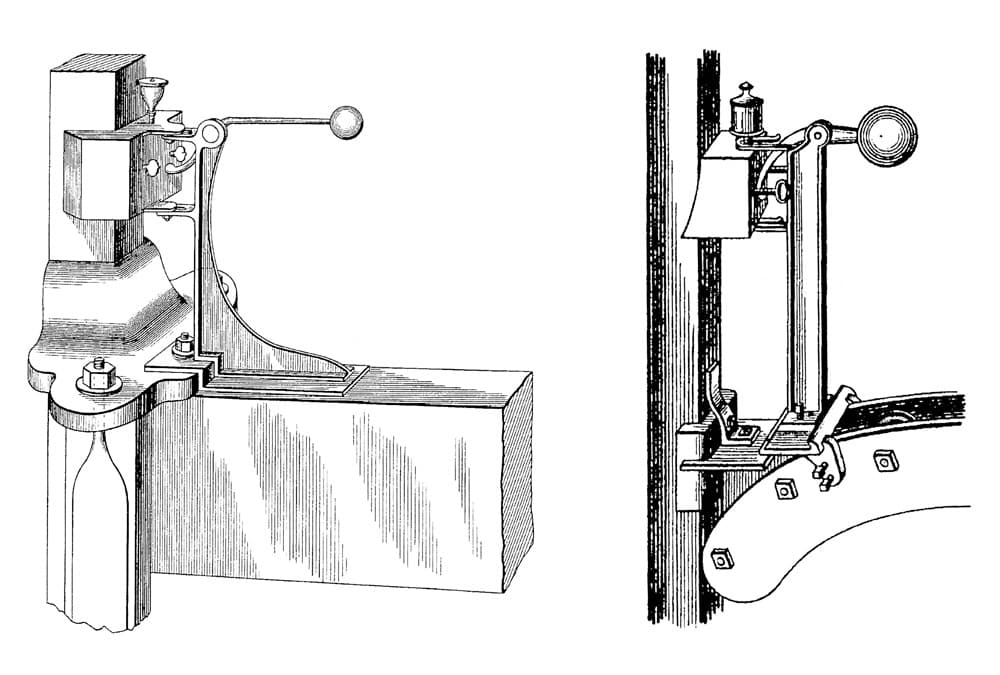

The first U.S. patent for a guide lubricator appeared in 1888; however, the patent text clearly implies that automatic lubricators existed prior to this date. Boston mechanic Michael P. Coleman described his invention as related “to that class of lubricators which are employed in lubricating the ways of elevator-carriages. . . [and] now in ordinary use.”[2] His design consisted of two primary components: cups, “partially filled with oil,” that were attached to the guide rails “below the lowest point to which the carriage descends” and weighted, hinged levers, which were equipped with wheels “covered with felt or any other absorbent material” and attached to the bottom of the car.[2] He described the lubricator’s operation as follows:

“When the carriage descends, the wheel will enter the cup, and its felt covering become saturated with oil, and as the carriage traverses the well, said wheel will be kept constantly in contact with the way by the weight, thus lubricating it in a manner which will be readily apparent without a more explicit description. In case the carriage accidentally descends at any time below the lower end of its route and the wheels [strike] the bottom of the cups, the joint between said lever and the arm will yield or be bent outwardly. . . thereby preventing injury to the cup and other parts of the lubricating apparatus.”[2]

The location of the oil-filled cups at the bottom of the shaft meant that the upper portions of the guide rails did not receive the benefit of Coleman’s automatic lubricator. In fact, his design was the only one that placed the lubricating device on the bottom of the car (Figures 1 and 2).

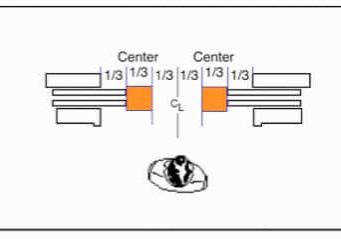

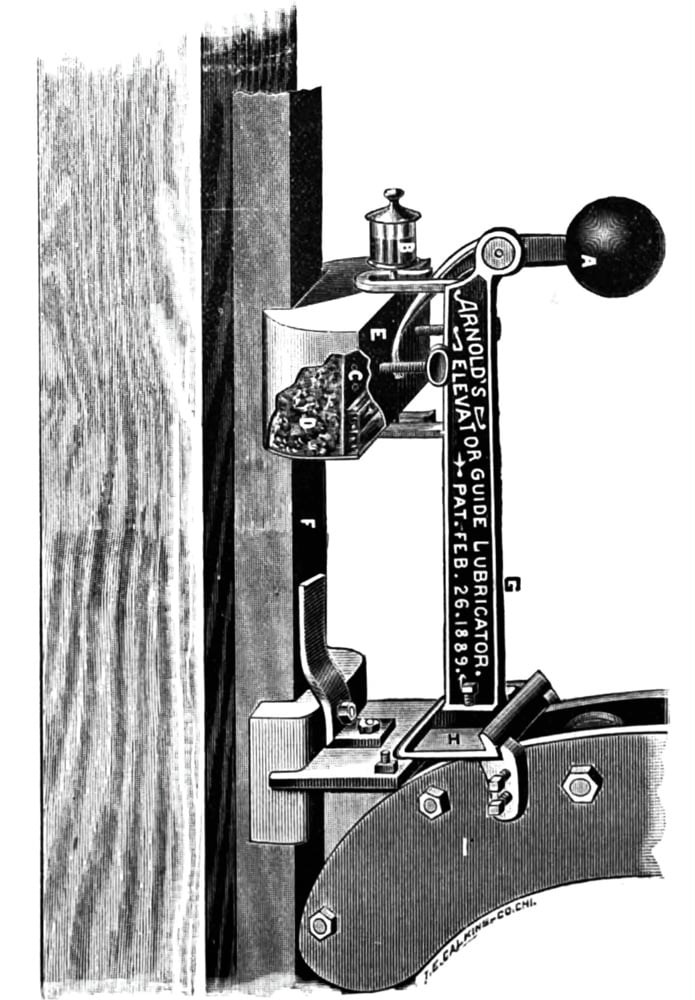

James M. Arnold, a Chicago machinist, received the next two patents for an automatic guide lubricator: “Lubricator for Elevators,” U.S. Patent No. 398,685 (February 26, 1889) and “Lubricator for Elevators,” U.S. Patent No. 437,351 (September 30, 1890). His design was also intended to “automatically lubricate the guides of an elevator at all times and avoid the necessity of stopping the elevator. . . for the operator to lubricate it or for someone to ride on the cross-beam to perform the same purpose.”[3] (The later statement serves as a reminder of the dangers associated with elevator maintenance in the 19th century.) Arnold’s design employed a cup that was “bifurcated to overlap or straddle the elevator-guide.”[3] The cup contained an asbestos pad, which was impregnated with oil that was fed to the pad from a small reservoir located on top of the cup. The pad was fitted into a bracket such that, as the pad became “worn by contact with the guide,” it could be easily adjusted.[3] The pad was also held steady against the guide by a weighted lever. The lever was intended to compensate for the “oscillating movement of the carriage which occurs in the operation of the elevator.”[3]

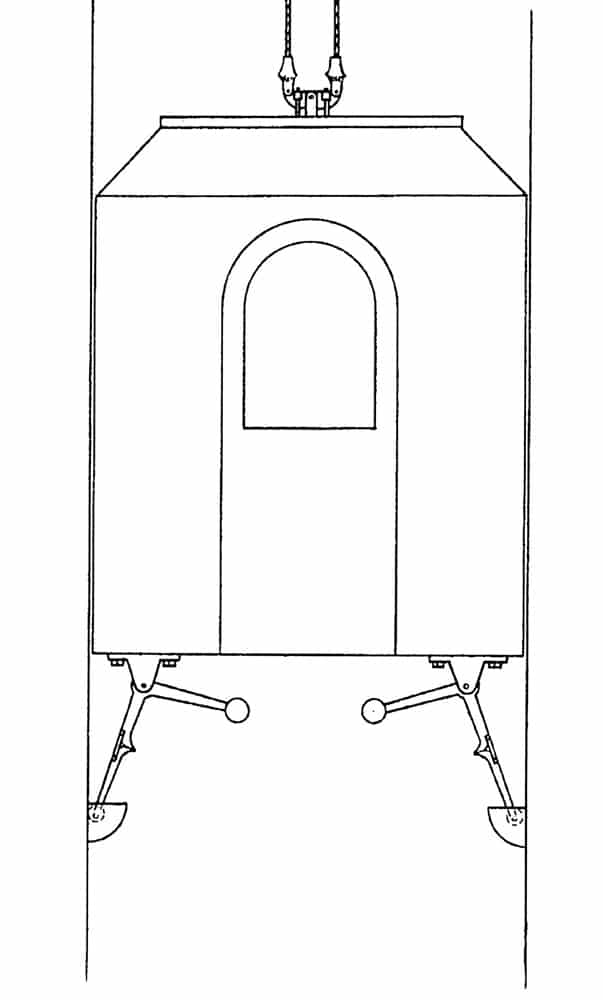

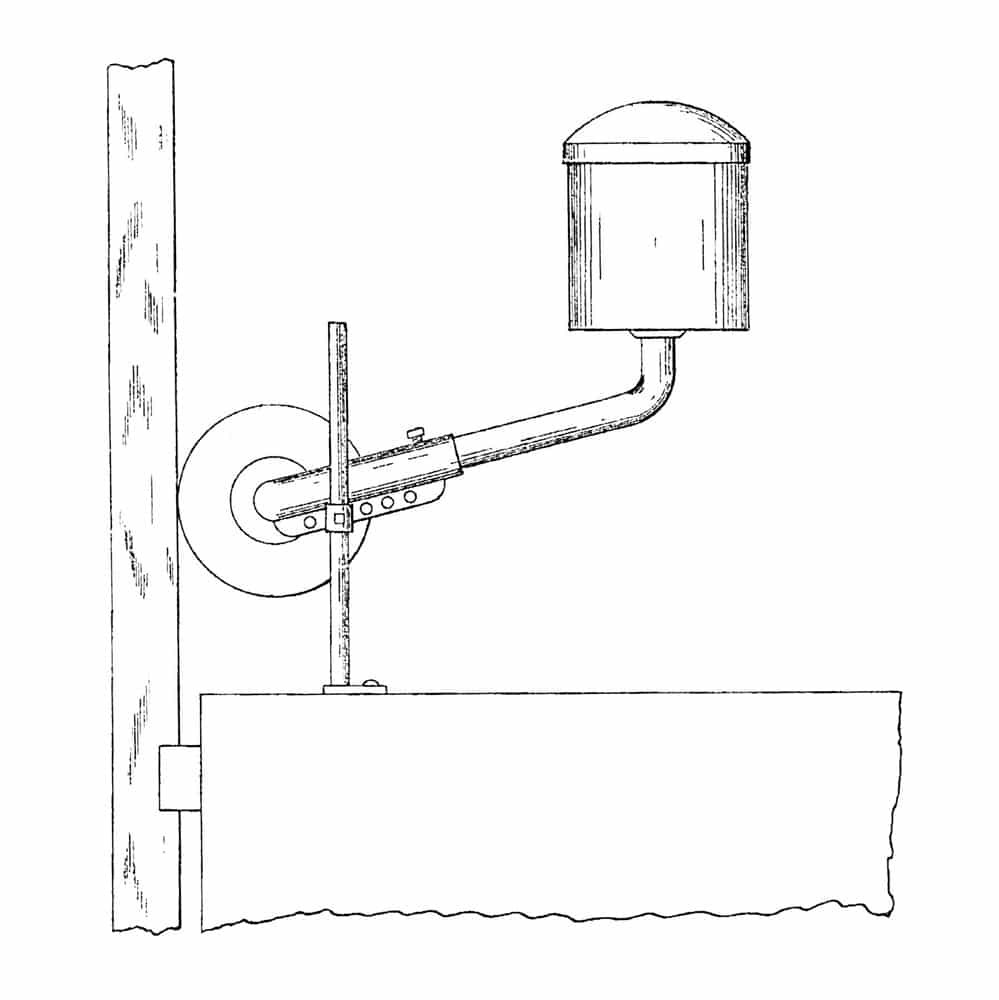

Arnold’s patent illustrations clearly indicate the subtle improvement of his design between 1889 and 1890, as well as his awareness of actual elevator car construction as seen in the 1890 patent drawings (Figure 3). His 1890 patent was the basis for the Arnold Elevator Guide Lubricator manufactured by M.B. Skinner & Co. of Chicago (Figure 4). An illustrated article that appeared in the June 4, 1890 issue of The American Engineer described the device as ideal for:

“. . . lubricating elevator guides, keeping them clean and in good condition. It can be attached to elevators already built and in use, without in any way interfering with their construction. It consists of a bifurcated cup, filled with asbestos fiber, kept thoroughly saturated with oil by means of an adjustable sight feed oil cup. This filling protrudes somewhat from the open portions of the cup, forming an oiled pad, which is pressed lightly against the guides by means of the weighted lever, all lateral play of carriages thus being compensated for by its continued action when the elevator is in motion. The pad not only lubricates the guides, but removes all dust and dirt, thus producing an oil finish or polished guide so necessary to obviate friction. Its use therefore saves power, does away with grease. . . and avoids the necessity of an engineer or helper making frequent trips on top of the carriages for the purpose of slushing the guides.”[4]

Although the extent to which Arnold’s lubricator was used is unknown, the article reported that it had been “highly commended by the Crane Elevator Co., Hale Elevator Co., Eaton & Prince and the J.W. Reedy Elevator Manufacturing Co.”[4]

The next lubricator patent was by a pair of inventors who were also from the Chicago area. In December 1890, Harrison M. Angle & Winter D. Hess of Evanston, Illinois, filed an application for a patent titled “Lubricator for Elevator Guides,” U.S. Patent No. 466,971 (January 12, 1892). As was the case with the previous inventions, the design problem was described in terms of the “trouble. . . experienced in the operation of elevators and lifts owing to the difficulty of keeping the guideposts properly lubricated.”[5] However, Angle and Hess provided an additional explanation of the problems caused by poor lubrication:

“As the weight in the car is liable to be constantly shifted and is rarely balanced, any deficiency in the lubrication of the guide-posts is not only liable to interfere with the running of the car by causing it to jump, as a result of excessive friction, but to wear the guide-posts and render the surface thereof uneven.”[5]

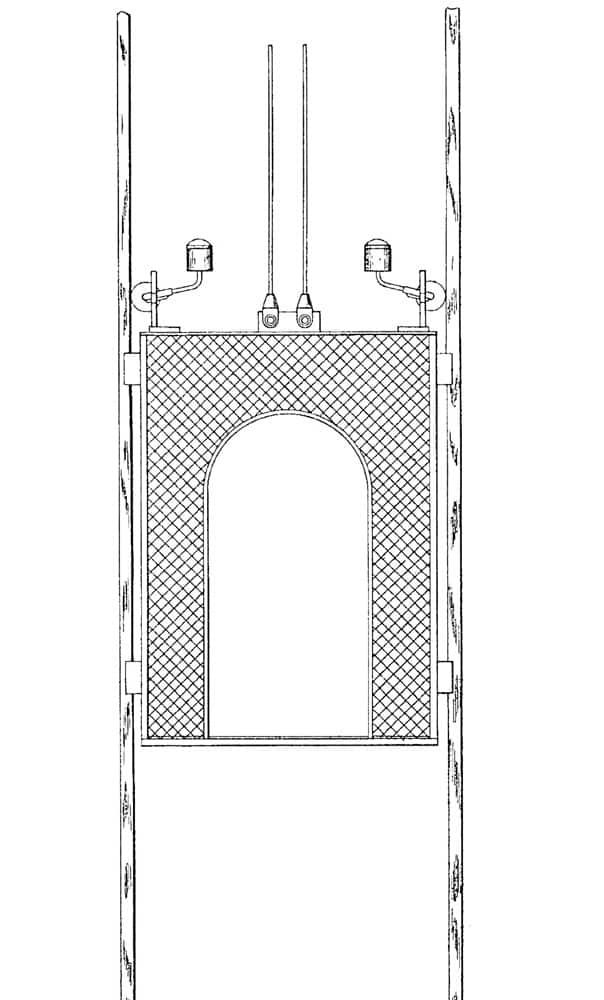

Thus, in this design, the lubricators were also called upon to act as guides capable of counteracting the actions of an unbalanced car as it moved through the shaft. Angle and Hess sought to solve this problem by employing three rollers, mounted in an iron frame, which embraced the guide rail. The rollers were fitted with springs that held them against the guide rail and allowed them to flex as the car traveled through the shaft (Figure 5). An oil supply cup, located atop the guide, dripped a steady stream of oil onto the rollers, thus lubricating the guide.

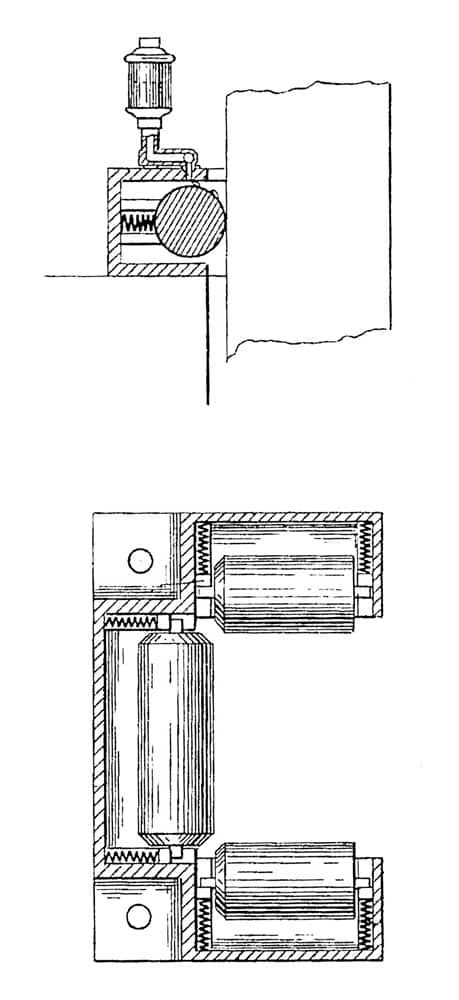

William J. Ferguson of Baltimore patented two designs for automatic lubricators: “Automatic Oiler for Elevator Guides,” U.S. Patent No. 517,272 (March 27, 1894) and “Lubricator,” U.S. Patent No. 531,993 (January 1, 1895). His first patent was similar to earlier schemes in that it provided continuous lubrication and was designed to accommodate variations in the guide surfaces. He employed an oil reservoir balanced on top of supply tubes connected to a hollow cylinder. The curving walls of the cylinder featured a series of small perforations, which allowed the oil to slowly escape (Figures 6 and 7).

Ferguson’s second patent also employed a roller topped by an oil reservoir; however, this design was more compact than the first and was not predicated on providing continuous lubrication:

“One of the objects of the invention is to provide a device of simple construction whereby the lubricating roller may be readily thrown into and out of contact with the vertical guides whenever it is desired to oil or grease them. Another object is to provide an improved automatic cut-off co-acting with the roller to cut off or let on the supply of oil or grease.”[6]

The “simple construction” that allowed the lubricator to be moved in and out of contact with the guide rail consisted of a series of springs and levers activated by a “hand-ring” attached to a long spring (Figure 8). The elevator operator was responsible for pulling on the ring, which caused the roller “to be projected out from its normal position into contact with the vertical guide.”[6] The operator would then “secure” the hand-ring “in any suitable way” or simply continue to hold it down until the guide had “been thoroughly lubricated.”[6] Ferguson did not, however, address how the operator accessed the hand-ring or the need to lubricate both guide rails and, thus, the prospective of needing to hold both rings down simultaneously. Although it was not uncommon for operators to participate in the basic maintenance of their respective elevators, the prospect of an operator reaching through an opening in the roof of the car to activate the lubricators while running the car offers an intriguing image.

The remaining 19th-century lubricator patents were filed by George A. Hofmeyer, a mechanical engineer working in New York City: “Lubricator,” U.S. Patent Nos. 515,586 (February 27, 1894) and 577,658 (February 23, 1897). These designs were variations on the roller lubricators patented by Angle and Hess in 1892. Hofmeyer’s patent text also matches that of the previous designs in that it attempts to place elevator guide lubrication in the realm of what Cullmer later referred to as the “economical and scientific operation” of elevators. These automatic devices were designed to remove the human element from this aspect of elevator maintenance, replacing it with the scientific precision of modern technology. The fact that several of these devices had design and operational flaws does not diminish the goal of creating the proverbial well-oiled machine.

Figure 1: Michael P. Coleman, “Lubricator,” U.S. Patent No. 380,023 (March 27, 1888)

Figure 3: L-r: Coleman, “Lubricator for Elevators,” U.S. Patent Nos. 398,685 (February 26, 1889) and 437,351 (September 30, 1890)

Figure 4: The Arnold Elevator Guide Lubricator (1890)

Figure 5: Harrison M. Angle and Winter D. Hess, “Lubricator for Elevator Guides,” U.S. Patent No. 466,971 (January 12, 1892)

Figure 6: William J. Ferguson, “Automatic Oiler for Elevator Guides,” U.S. Patent No. 517,272 (March 27, 1894)

Figure 7: Ferguson, “Automatic Oiler for Elevator Guides”

Figure 8: Ferguson, “Lubricator,” U.S. Patent No. 531,993 (January 1, 1895)

References

[1] H. Robert Cullmer, “Elevator Shaft Construction” (William T. Comstock Co.: 1912).

[2] Michael P. Coleman, “Lubricator,” U.S. Patent No. 380,023 (March 27, 1888).

[3] James M. Arnold, “Lubricator for Elevators,” U.S. Patent No. 398,685 (February 26, 1889).

[4] “Elevator Guide Lubricator,” The American Engineer, Volume 19 (June 4, 1890).

[5] Harrison M. Angle & Winter D. Hess, “Lubricator for Elevator Guides” U.S. Patent No. 466,971 (January 12, 1892).

[6] William J. Ferguson, “Lubricator,” U.S. Patent No. 531,993 (January 1, 1895).

Get more of Elevator World. Sign up for our free e-newsletter.