Automated People Movers

submitted by David Cooper, LECS (UK) Ltd.

Emirates Air Line is the U.K.’s first urban cable car. It provides a low-emission, direct and accessible link across the Thames River, traveling between two new terminals, Emirates Greenwich Peninsula and Emirates Royal Docks. It was completed in June 2012 and erected prior to the 2012 London Olympic Games. It sits amongst some of London’s most popular buildings, including Canary Wharf, The Gherkin, Tower 42, The Heron Tower, The BT Tower and the recently completed, The Shard. The latter was also constructed by MACE, the contractor of Emirates Air Line.

Analysts considered all options for a transportation system including a bridge, water-based transportation and a tunnel. The cable car was selected as the preferred option for a number of reasons, including cost, program and aesthetics. The system endured several engineering challenges, including a short allotted timeframe.

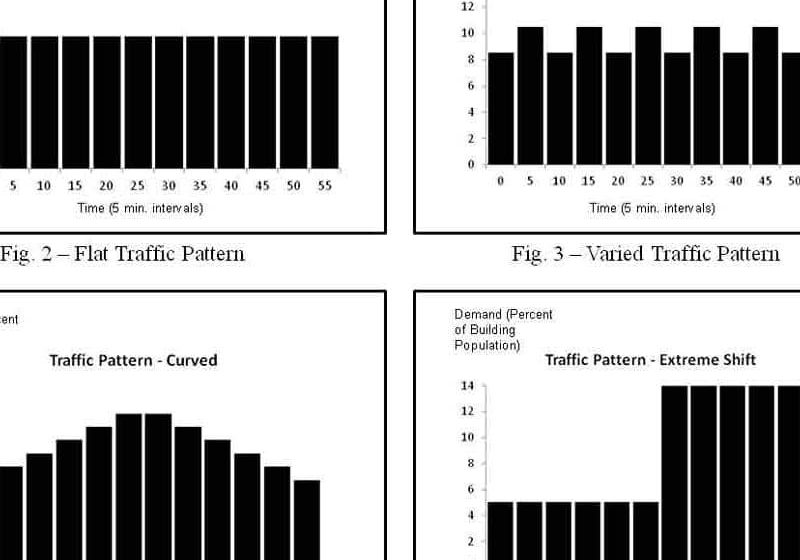

The system consists of 34 cabins, each with a carrying capacity of 10 passengers. It can operate at speeds up to 6 mps and, at that speed, takes 4 min., 14 s. to complete a one-way crossing. It is capable of transporting 2,500 people per hour, a significant number, especially during the Olympic Games. It also provides a major new passenger route from the O2 Arena on the south side of the Thames River to the north side just west of ExCeL London, a major exhibition center.

The unique aspects of the project called for innovative construction techniques and a number of firsts in the industry. For example, the erection of the South Tower required the installation of the largest lifting-capacity crawler crane in Europe. The crane, which runs on tracks (instead of wheels) to aid mobility, was put together on site over a period of two weeks and delivered using more than 70 articulated lorries. Its reach is 120 m, with a height of 183 m. The large temporary structure, dubbed LR 1350, had a maximum lifting capacity of 1,350 mT — the equivalent of 193 Routemaster buses. The immense lift capacity was required to lift pieces of each tower into place, some of which weighed up to 68 mT each.

Both areas surrounding Emirates Air Line have been earmarked for several projects with the Royal Victoria Docks, selected as one of the new Local Enterprise Zones. The line will play a key role in supporting these projects by providing a quicker and more-direct link. It will also provide access to a range of entertainment, professional and leisure opportunities. On its first day in operation, the system transported more than 20,000 people and has proved to be reliable and effective. Between June 28 and August 12, 2012, the system carried more than 700,000 people.

Transportation System

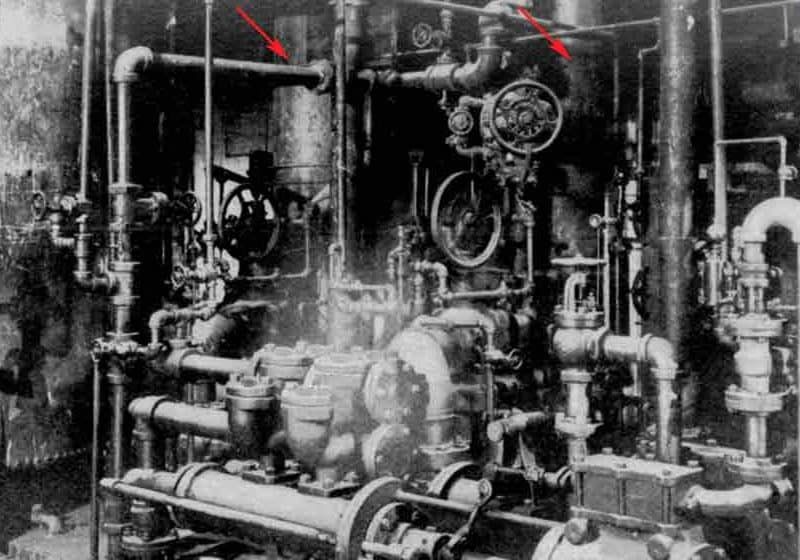

The transportation system consists of a continuous single rope measuring 50 mm, to which up to 34 cabins can be attached. The system is efficient and, as with a traction elevator, only has to provide power to move the out-of-balance load when the cabins are out on the line and equally spaced.

The system had to be fully accessible for persons with mobility impairments and has a feature that allows cabins to stop for loading and unloading, whereas in normal operation, the cabins keep moving slowly in the station areas. In order to achieve this, an anti-collision system had to be designed into the software.

One of the initial challenges involved trying to construct the two main towers (both 86 m tall and weighing 570 mT) to accommodate the river crossing and one smaller intermediate tower, which measures more than 65 m in height and weighs 270 mT. The size of the towers, the fact that one had to be positioned in the Thames River and the need for exacting stability as a core requirement for the operation of the cable car also presented several challenges. However, the design of the towers, using a complex helix structure to link the four steel ribbons, assisted in providing the needed stability. The towers, made of approximately 6,500 pieces of steel of varying thicknesses (30-50 mm), were then welded together before being connected to helix tubes that run inside the tower and provide the required stiffness.

There are three main towers and two compression towers. The main towers support the system at height, and the compression towers provide rope diversion from the stations to the head of the towers. The main towers had to be constructed to allow for a 51-m-tall ship to pass under the system at high tide, which is scheduled for twice a day. Each tower has been topped with a Doppelmayr head (named after a cable-car contractor), which allows the cabling to run across the tops of the structures. The cable is made of twisted steel comprised of 300 separate strands, is 50 mm thick and stretches 1.1 km across the river. The use of boats was required to make the initial rope connection during the short allotted timeframe during low tide. The cable was pulled into place and tensioned using a 12-T winch located on the platform of the South Terminal (Emirates Greenwich Peninsula). The cable was clamped and secured at each terminal and tensioned to gain a minimum clearance of 54 m above the high-water mark.

The system has a traction sheave and return pulley/diverter sheave, which is tensioned in a similar fashion to an escalator step chain. Once the cable had been tensioned to the correct height, the next step was to carry out the rigorous testing and commissioning process for the whole system. Another engineering challenge faced was that of the flight path into the nearby London City Airport. The lower end of the emergency approach into the airport is 110 m, only 23 m above the top of the south tower.

Designers also had to be aware of the possibility of a vessel striking a tower. Though the risk was assessed as low, a ship-impact system was employed to divert any risk away from the towers. The south tower has been constructed in the main river itself, which, again, presented challenges along with the limited construction timeline. The project began in July 2011 and was handed over on June 28, 2012. Completing the project in a little over 10 months is quite an achievement, given the design and construction challenges.

After the design stage, construction issues were also abundant. The U.K. had its worst recorded period of inclement weather during construction, when the region saw heavy rain on most days, as well as a period of snow.

The bed of the Thames River was found to be unstable, which was no surprise given an earlier discovery of this kind in the 1800s after similar weather. However, it wasn’t anticipated that the problem would be some 30 m deeper than expected.

Another challenging issue was designing the system in such a way that all passengers could be retrieved in a timely manner in the event of equipment failure. The design is such that there is redundancy and system support including an innovative emergency bearing system, incorporated in case of a bearing failure on the main traction and tensioning sheaves. The bearing design was developed specifically for this project, which marks its first use; however, the success of the design means it will likely be adopted for future projects around the world.

Get more of Elevator World. Sign up for our free e-newsletter.