Effortless Access, Stunning Design

Feb 1, 2023

Next Level Elevators completes challenging residential project in Australia.

by Caleb Terpstra

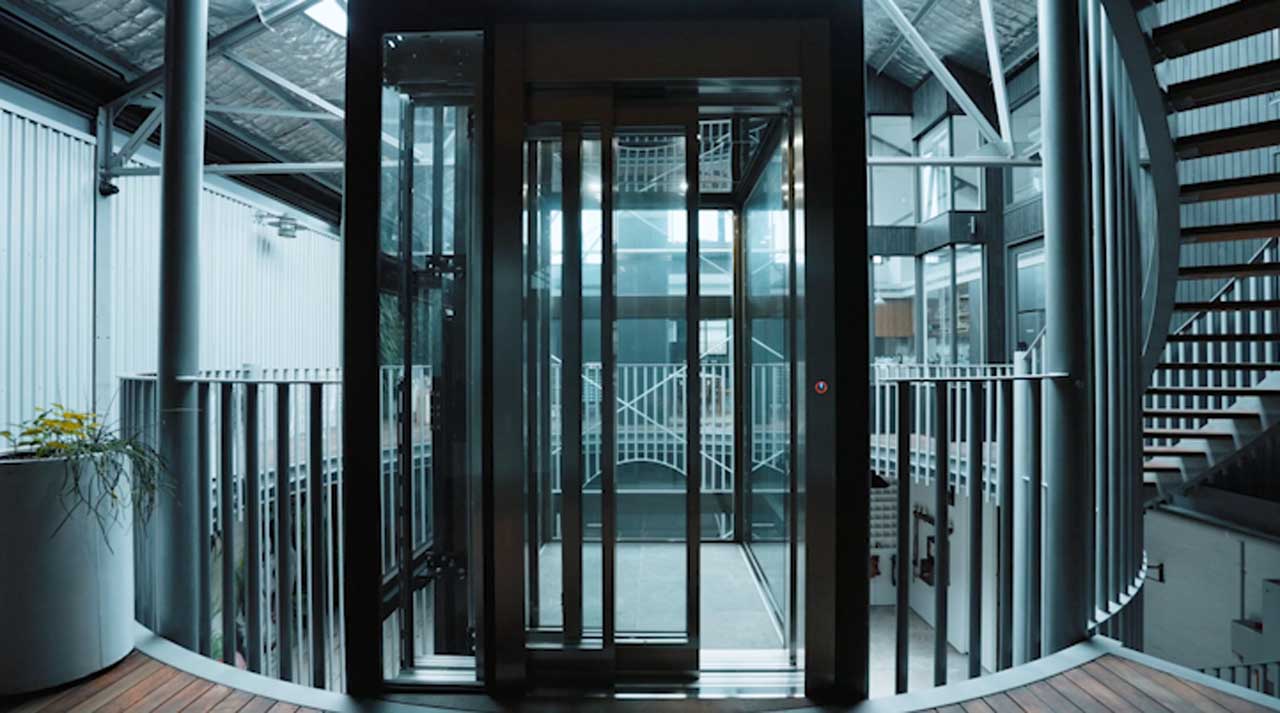

The Pottery is an innovative residential project in New South Wales, Australia, that saw Next Level Elevators install an eye-catching Eltec HLG elevator within an open-air courtyard. The vision was for the courtyard to act as a central hub within the home and provide effortless access throughout.

The project required a highly customized three-stop Eltec HLG elevator. Finishes included our iconic glass elevator shaft in a sophisticated bronze finish, complete glass cabin, seamless sliding doors, tower control panel and a custom stone floor.

Next Level Elevators worked closely with the owner, architect and builder to ensure the elevator met the vision for the space.

Visual Requirements

There was a natural level of synergy between the visual requirements for the project and the modern design aesthetic of the Eltec HLG. The entire build has a contemporary edge, and each area finds ways to exceed expectations. The considerable use of glass allows for the elevator to be a statement piece, while simultaneously blending with its surroundings, ultimately softening what would otherwise be a very imposing structure. The bronze shaft creates a beautiful contrast against the circular stairway while complementing the other earthy tones within the space. The paired back design approach, which features limited furnishings, allows for the major architectural elements to come to the forefront, namely, the stairway and Eltec HLG.

Practical Requirements

Key excerpts from the architectural plans show how pivotal the central courtyard is to the overall design and function of the home. Ease of access is key to the layout, and without the Eltec HLG, the viability of the space would be significantly diminished.

An open roof within a central part of the home is quite an innovative concept, especially when the space below acts as a major junction. Consequently, this kind of execution required significant consideration from both the builder and Next Level Elevators. Thankfully, the distinctive glass elevator shaft, known technically as a “TA Freestanding Shaft,” was the ideal solution with its water-resistant qualities and premium design aesthetic.

The TA Freestanding Shaft is a self-supporting frame made entirely of aluminum with a modern and harmonious design (ultra-smooth design by Eltec). Aluminum is recyclable and respects the environment. It combines lightness and flexibility with great resistance and solidity. It resists corrosion over time and does not require maintenance. The TA frame is quick and easy to install thanks to its exclusive patented interlocking system. With total absence of screws and exposed wiring, it can be finished by choosing from a wide range of anodization and colors. Ideal for housing both lifting platforms and electric lifts with a capacity of up to 630 kg and a speed of 1 m/s, it can be developed for a height of 20 m.

This unique project required innovative technology. The Eltec HLG elevator boasts a variable voltage variable frequency, all-electric, gearless traction system, which is known for its energy efficiency, seamless operation, low wear and ease of install.

The enhanced motor in the Eltec HLG meant the elevator could have a complete glass cabin with glass sliding doors and not compromise on the client’s desired carrying capacity. Unlike hydraulic elevators, the Eltec HLG doesn’t require a motor room, as it is housed within the shaft. This streamlined design means that additional space doesn’t need to be stolen from the surrounding area and compromise the overall design. The 10 A single-phase power requirement means that the Eltec HLG is also one of the most efficient residential lifts on the Australian marketplace and meets sustainability expectations.

Installation Overview

From small streetscapes, COVID-19-related issues, limited access and record rainfall, this inner-city installation came with a host of challenges. Despite these barriers, Next Level Elevators’ highly trained staff and refined installation processes helped keep the project on track. Small streets and limited access were overcome via our flat-packed assets, a versatile all-terrain forklift and traffic management processes. Next Level Elevators also worked closely with the builder to minimize the impact of record rainfall on-site.

Shaft Installation

The aluminum shaft was installed with vertical and horizontal crossmembers that bolted together, allowing for the glazing installation. The frame was fixed to the internal floor voids to prevent movement and ensure required lift loads were met. The frame was squared using piano wire and string lines. Glass panels were set in place using an electric winch in conjunction with glass suckers. The weatherproof roof was then installed with bolts via the vertical aluminum profiles on top.

Lift Installation

- Installation of guide brackets and rails: Brackets that house the guide rails were mounted to the aluminum structure and leveled using piano wire. The 2.5-m length of guide rails were joined using fishplates.

- Installation of gearless motor: The motor bed plate was attached to the top of the guiderails, and the motor itself was mounted on top using six high-tensile bolts.

- Installation of car sling and floor: The car sling was built inside the lift guide rails and secured using nylon guide shoes. The car floor was then bolted to this sling.

- Installation of doors: The landing door frames were installed at specific points in the shaft to ensure they lined up perfectly with the center of the car. Once completed and correctly secured, the sliding doors were then mounted to the frames.

- Installation of the car frame: This was built and attached to the car floor using precision-made aluminum profiles, which consisted of four corner posts and a roof section. The car walls were then installed using the same method as the glass installation, i.e., with snap beading and rubber seals.

- Electrical installation: All electrics were installed as per the electrical manual and various tests completed to ensure the highest standards were met.

The enhanced motor in the Eltec HLG meant the elevator could have a complete glass cabin with glass sliding doors and not compromise on the clients’ desired carrying capacity.

Get more of Elevator World. Sign up for our free e-newsletter.