Elevator Certification Processes – Global Approach and Regional Certification

Oct 1, 2012

How Global Certification Organizations can help manufacturers understand the different certification processes

by Dirk Schroeter and Carsten Schumann

This paper was presented at  USA 2012, the International Congress on Vertical Transportation Technologies and first published in IAEE book Elevator Technology 19, edited by A. Lustig. It is a reprint with permission from the International Association of Elevator Engineers

USA 2012, the International Congress on Vertical Transportation Technologies and first published in IAEE book Elevator Technology 19, edited by A. Lustig. It is a reprint with permission from the International Association of Elevator Engineers  (website: www.elevcon.com). This paper is an exact reprint and has not been edited by ELEVATOR WORLD.

(website: www.elevcon.com). This paper is an exact reprint and has not been edited by ELEVATOR WORLD.

Key Words: Certification, AECO, Notified Body, elevator acceptance, safety

Abstract

In the global world of today, the manufacturers and installers of elevators (lifts) and elevator components want to place their products on all markets. The two existing approaches – the European Lifts Directive (Certification of products) and the North American ASME A17.7/CSA B44.7 (Certification of deviations) – are disparate in their application. TÜV SÜD as an AECO per ASME A17.7/CSA B44.7 (TÜV SÜD America Inc.) and a Notified Body per European Lifts Directive (TÜV SÜD Industrie Service GmbH) will explain the different elevator certification procedures to meet the applicable certification requirements.

1. Background

The most applied and accepted elevator design standards (codes) worldwide are the North American Safety Code for elevators and escalators ASME A17.1/CSA B44 and the European Harmonized Standards EN81-1 and EN81-2. Therefore, most of the elevator and elevator component manufacturers design their products in accordance with the requirements of one of these standards. Because of this, manufacturers or installers (hereafter manufacturers) who want to place these elevators and components on the major global markets most likely will have deviations to the respective standard not used for the design. Since the North American Performance-based Safety Code for elevators and escalators, ASME A17.7/CSA B44.7, was published, a structured process was established to demonstrate compliance of an elevator and its components with deviations to ASME A17.1/CSA B44 through a Certification of Conformance by an Accredited Elevator/Escalator Certification Organization (AECO). Using EN81-1 or EN81-2, a manufacturer with an elevator or component deviating from the requirements of these European Harmonized Standards needs to apply with a Notified Body for an EC type-examination or a design examination to demonstrate compliance with the applicable Essential Health and Safety Requirements as identified in Annex I of the Directive 95/16/EC on Lifts. This paper will give an overview of both existing certification procedures to explain manufacturers the differences in their applications.

2. European Lifts Directive

The Directive 95/16/EC on Lifts belongs to the European New Approach Directives, which were developed to support the creation of a common European Market to reach free movement of goods through the prevention of barriers to trade, mutual recognition, and technical harmonization and standardization.

These general goals are addressed by each European New Approach Directive through mandatory Essential Health and Safety Requirements to ensure a certain level of protection, conformity assessment through defined procedures (modules), and the possibility to apply harmonized standards to reach a “presumption of conformity.”

Furthermore, the process allows the application of other technical specifications/standards to implement innovative and more efficient technology through showing compliance with the Essential Health and Safety Requirements of the European Directives.

Involved in this conformity assessment may be Notified Bodies which are accredited according to the applicable European Directive(s) and the manufacturer of the respective product.

The “European Parliament and Council Directive 95/16/EC of June 29, 1995 on the approximation of the laws of the Member States relating to lifts” applies to elevators, as well as safety components, and must be used to place these products onto the European Market.

Elevators and safety components (defined in Annex IV of the Lifts Directive) need to go through a defined Conformity Assessment Procedure and must fulfill all applicable Essential Health and Safety Requirements relating to the design and construction of elevators and safety components respectively.

Safety components must satisfy the Essential Health and Safety Requirements or enable the elevators in which they are installed to satisfy these requirements.

With utilizing European Harmonized Standards like EN81-1 and EN81-2, the manufacturer will have the “presumption of conformity” to fulfill the Essential Health and Safety Requirements.

However, deviations to harmonized standards or the use of other technical specifications/standards are permitted, as long as the Essential Health and Safety Requirements are met, and a Notified Body performs an EC type-examination or a design examination for compliance respectively with the requirements in Annex I of 95/16/EC.

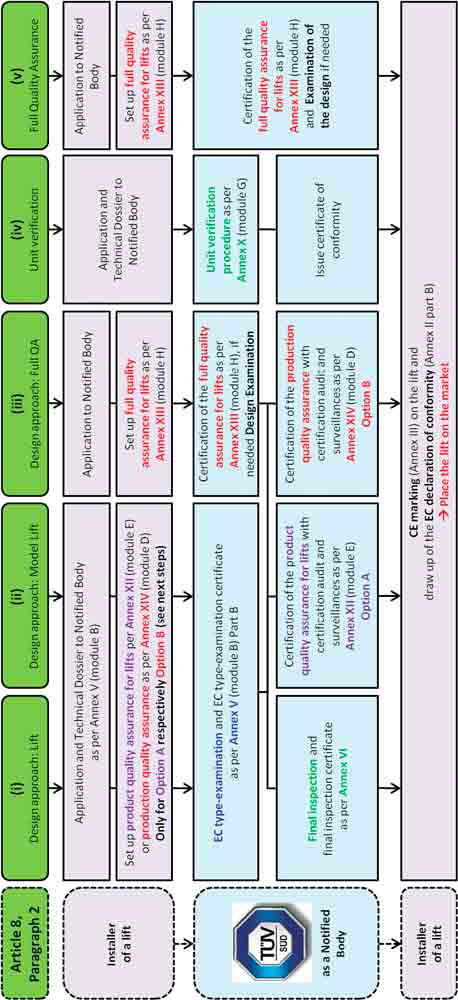

A diagram showing the defined Conformity Assessment Procedures for elevators in accordance to Article 8 Paragraph 2 of Directive 95/16/EC is given in figure 1.

Prior to an elevator being placed on the European Market, it must have undergone one of five (5) possible procedures, and the installer of the elevator must affix the CE marking (as per Annex III of Directive 95/16/EC) on the elevator and issue an EC declaration of conformity (as per Annex II part B of Directive 95/16/EC) for the elevator.

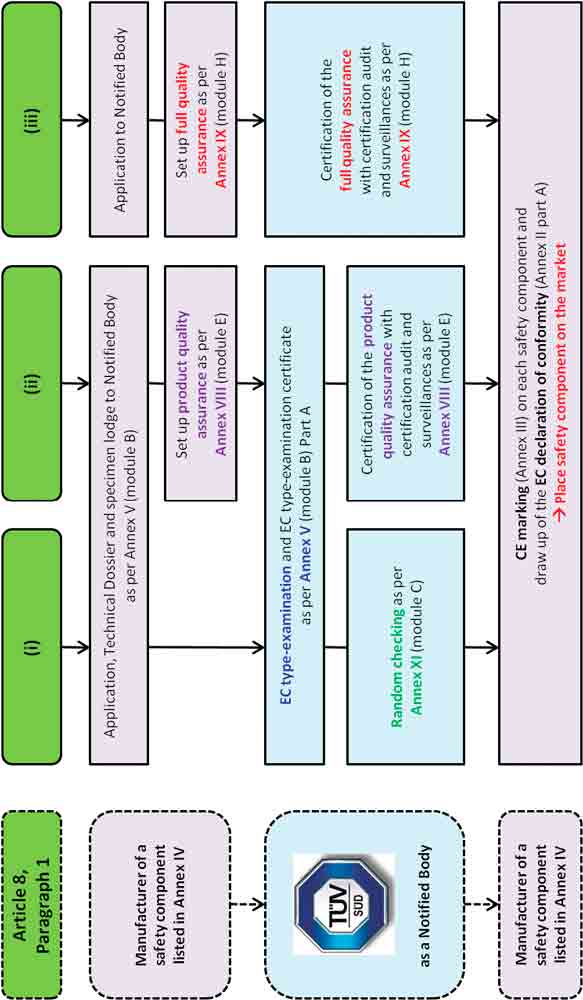

An overview of possible Conformity Assessment Procedures for safety components according to the Lifts Directive 95/16/EC is given in figure 2.

Before placing a safety component on the European Market, the manufacturer must perform one of the three (3) options shown in figure 2 and, in addition, affix the CE marking (as per Annex III of Directive 95/16/EC) on each safety component and issue a EC declaration of conformity (as per Annex II part A of Directive 95/16/EC) to meet the requirements of the Conformity Assessment Procedure specified in Article 8 Paragraph 1 of Directive 95/16/EC

3. North American Codes

The Safety Code for elevators and escalators, ASME A17.1/CSA B44, covers the design, construction, operation, inspection, testing, maintenance, alteration, and repair of elevators, escalators, and moving walks, as well as dumbwaiters. A manufacturer of elevators will find acceptance with most of the Authorities Having Jurisdiction in North America when applicable requirements of this prescriptive Safety Code are fulfilled. There are also Authorities in other regions of the world which accept ASME A17.1/CSA B44 as a prescriptive Safety Code for elevators and its components. Since the Performance-Based Safety Code for elevators and escalators, ASME A17.7/CSA B44.7, was published and three (3) Certification Organizations were accredited as an AECO, the North American Safety Code ASME A17.1/CSA B44 enables now manufacturers to implement innovative and efficient elevator technology which is not yet addressed in ASME A17.1/CSA B44 through showing compliance with ASME A17.7/CSA B44.7. An equivalent level of safety will be ensured when the elevator system, sub-system, component, or function meets applicable Global Essential Safety Requirements as defined in Part 3 of ASME A17.7/CSA B44.7.

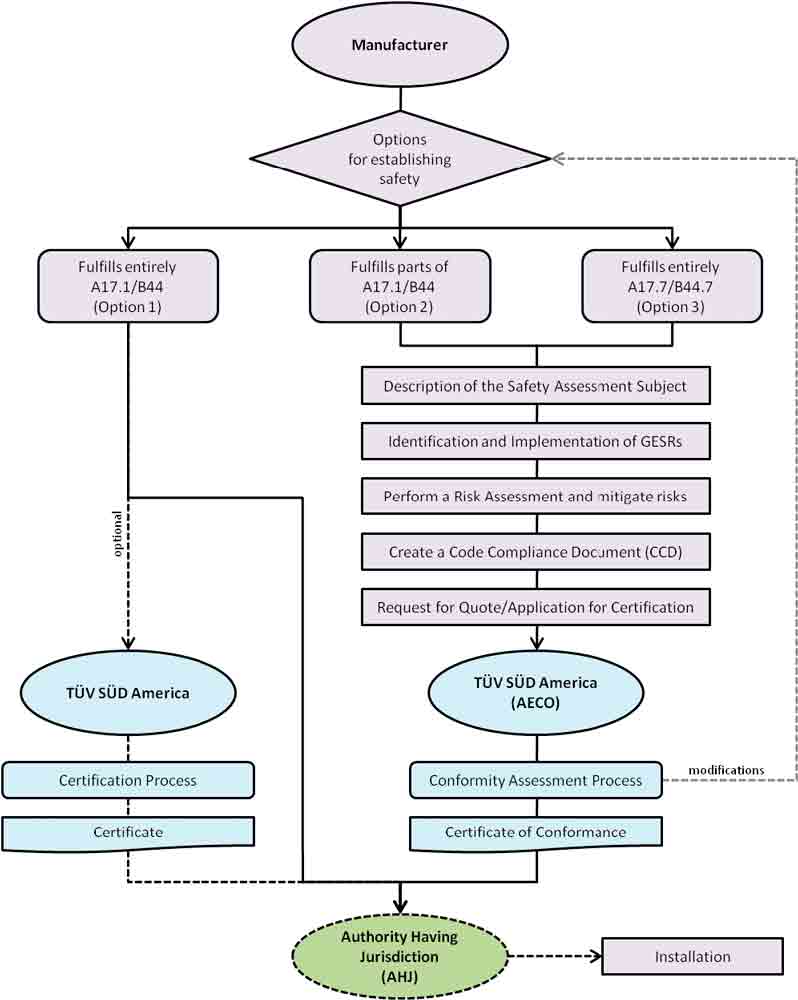

The options for establishing safety of elevator systems, sub-systems, components, or functions in accordance with ASME A17.1/CSA B44 are shown in figure 3. The first option is to follow ASME A17.1/CSA B44 requirements and represents the conventional process for establishing elevator safety used by satisfying all applicable requirements of the Safety Code for elevators and escalators. The Performance-based Safety Code ASME A17.7/CSA B44.7 establishes two additional ways – option 2 to fulfill parts of ASME A17.1/CSA B44 and conform to applicable requirements of ASME A17.7/CSA B44.7 for the deviation(s), or option 3 to fulfill ASME A17.7/CSA B44.7 entirely for e.g. radically different elevator systems, sub-systems, components, or functions as addressed in the Safety Code.

The certification process described in ASME A17.7/CSA B44.7 and the tasks of involved parties are shown in figure 4.

As shown in figure 4, the manufacturer can voluntarily involve a Certification Organization for a compliance certification with ASME A17.1/CSA B44 to support the acceptance process with the respective Authority Having Jurisdiction in option 1 for establishing safety. For a certification in accordance to options 2 and 3 of establishing safety, the manufacturer must prepare the Technical Documentation as required in ASME A17.7/CSA B44.7 including, for example, a description of the Safety Assessment Subject, a list of identified and implemented Global Essential Safety Requirements, and the Risk Assessment Records compiled all together with the Code Compliance Document. The manufacturer can then apply for a Certification of Conformance with an AECO. The Technical Documentation is needed to demonstrate to the AECO that applicable Global Essential Safety Requirements are met, and that an equivalent or higher level of safety as required in ASME A17.1/CSA B44 will be achieved. After evaluation of the Technical Documentation and the verification of the product or function at the place of manufacture, TÜV SÜD America Inc., as an AECO, will issue a Certificate of Conformance when the Conformity Assessment Process comes to a positive result. The parts being subjected to the ASME A17.7/CSA B44.7 certification process need to bear the AECO certification mark, such as the certification mark of TÜV SÜD America Inc. (figure 5). In addition, TÜV SÜD America Inc. will then monitor the manufacturer in ongoing surveillances to verify that the certified equipment is being produced to the requirements defined in the CCD and the Certificate of Conformance.

4. Comparison Of The European Lifts Directive And The North American Performance-Based Safety Code

Since the North American Code ASME A17.7/CSA B44.7 was published, the approach of using Global Essential Safety Requirements instead of prescriptive design requirements is comparable to the concept of the European New Approach Directives using Essential Health and Safety Requirements. The Conformity Assessment Process with involvement of an AECO describes a structured and defined method like the Conformity Assessment Procedures with a Notified Body.

However, the major difference between both certification processes is that the responsibility for the acceptance of an elevator in accordance to the North American Performance-based Safety Code ASME A17.7/CSA B44.7 rests not with the AECO, as in the European Directive 95/16/EC on Lifts with the Notified Body. The AECO assesses deviations of an elevator system, sub-system, component, or function to ASME A17.1/CSA B44 and does not evaluate the compliance of the elevator with the applicable requirements of the prescriptive Safety Code, which will be done by the respective Authority Having Jurisdiction. An AECO does a “certification of deviations.” A Notified Body does “product certifications.” That means a Notified Body certifies compliance with the Essential Health and Safety Requirements and European Harmonized Standards (if applicable), and in addition, does design examinations when a product deviates from a harmonized standard or when other technical specifications/ standards had been used to meet the requirements of the European Lifts Directive. Therefore, the Notified Body gives acceptance of elevators and its components like an Authority Having Jurisdiction in North America or an Authority Having Jurisdiction applying North American Codes.

As a result, the acceptance of a Certificate of Conformance issued by an AECO in accordance to ASME A17.7/CSA B44.7 is not mandatory for an Authority Having Jurisdiction. The certification must be seen as a helpful tool for a manufacturer to support a variance process with an Authority Having Jurisdiction to demonstrate that an equal level of safety as defined in ASME A17.1/CSA B44 will be reached by the elevator system, sub-system, component, or function which deviates from the Safety Code.

5. Global Needs Satisfied Through Regional Certifications

Global Certification Organizations, such as TÜV SÜD with its subsidiaries TÜV SÜD Industrie Service GmbH as a Notified Body and TÜV SÜD America Inc. as an AECO, support manufacturers in placing elevators and its components on major markets through regional certifications in accordance with the European Lifts Directive 95/16/EC and the North American Performance-based Safety Code ASME A17.7/CSA B44.7 to certify compliance with the Essential Health and Safety Requirements, as well as with the Global Essential Safety Requirements.

6. Conclusions

Although, there is no existing Global Certification and Acceptance Approach for elevators and its components, manufacturers now have, through certifications in accordance to the Directive 95/16/EC on Lifts by a Notified Body and in accordance to the Performance-based Safety Code ASME A17.7/CSA B44.7 by an AECO, the possibility to find better acceptance on major global markets for products which comply with either the North American Safety Code for elevators and escalators ASME A17.1/CSA B44 or with the European Harmonized Standard EN81-1 and respectively EN81-2. Even though the method of using protective goals like Global Essential Safety Requirements in ASME A17.7/CSA B44.7 and Essential Health and Safety Requirements in the Lifts Directive is the same, the application of both approaches is different. Thus, Global Certification Organizations such as TÜV SÜD help manufacturers to understand the different certification processes and offer both certifications through their regional accredited subsidiaries out of one hand.

It is now up to the manufacturers to use the different approaches to carry on the idea of a Global Certification Approach for elevators and its components and to meet the demands of this globalized world.

REFERENCES

ASME A17.1/CSA B44, Safety Code for Elevators and Escalators, Latest edition 2010

ASME A17.7/CSA B44.7, Performance-based safety code for elevators and escalators, First edition 2007

Directive 95/16/EC on Lifts, EUROPEAN PARLIAMENT AND COUNCIL DIRECTIVE 95/16/EC of 29 June 1995 on the approximation of the laws of the Member States relating to lifts http://ec.europa.eu/enterprise/sectors/mechanical/documents/legislation/lifts/index_en.htm

EN81-1, Safety rules for the construction and installation of lifts – Part 1: Electric lifts, Latest edition, EN 81-1:1998+A3:2009

EN81-2, Safety rules for the construction and installation of lifts – Part 2: Hydraulic lifts, Latest edition, EN 81-2:1998+A3:2009

Get more of Elevator World. Sign up for our free e-newsletter.