Elevator Efficiency: Is It All About Energy Consumption of the Elevator?

Apr 1, 2017

A look at important efficiency factors beyond energy consumption and oil usage

Fossil fuels are still extensively used to generate energy, despite huge investments in renewable energy sources. To reduce the rate of global warming, the best hope of significantly reducing emissions is to utilize available energy more efficiently.

Elevators are large engineering systems, designed and installed for a particular shaft in a building. Depending on their usage, from private houses to high-rise buildings, elevators consume only 2-10% of building energy. Therefore, considering only energy consumption of elevators may not be sufficient to recognize the carbon footprint of the complete system. However, today, the sector has been given a perception that only energy consumption and oil usage are the important factors to be considered. This perception has been used as a marketing tool by the large elevator companies to grasp the low-rise market, which has been dominated by hydraulic elevators.

The most effective development in this area is the use of an inverter with the permanent-magnet synchronization (PMS) machine to control lift speed. The development is also called the “new” or “latest” technology and offers considerably reduced operational energy consumption. With the introduction of machine-room-less (MRL) units’ improved efficiency and drive-control characteristics, it has become possible to install traction lifts in low-rise buildings. Focusing on the energy-consumption issue and using it as a marketing tool, MRL installations have managed to trend in the market.

The MRL solution has been reflected as always providing the most energy-efficient solution, perfectly suiting every installation and always regenerating energy and dumping it back into the grid. However, the mentioned benefits of the existing “new technology” are not remarkable and mostly lead to higher energy consumption when MRL technology is used for low-usage elevators,[1] where the investment for the new technology may never be gained back during the lifespan of the elevator.[2] This is because of the fact that the inverter and its peripheral devices are costly and require energy to be active, even when the lift is in standby.[3] On the other hand, it is expected that future developments in the drive technology, like matrix converters, would drastically reduce or eliminate standby energy consumption, and competition in the market will obviously lower inverter prices. In this respect, properties of environmentally suitable solutions will change to those that are simple, inexpensive, easy to maintain, offer high compatibility with existing systems and have low standby consumption. These are expected to find wide applications in coming years. In addition, while concentrating on energy consumption and oil usage, it has always been forgotten that MRL elevators are the least safe systems with respect to installations, service, robustness against seismic activities and rescue of entrapped passengers.

Lifecycle Analysis

Environmental impact of elevator systems has started gaining importance in the elevator sector because of the inclination toward optimum utilization of resources. Lifecycle analysis (LCA) is the method by which to determine the environmental impact of elevators. The lifetime of elevators is generally assessed to be 20-25 years. When it comes to modernization, reuse of hydraulic components becomes of prime importance for the user and environment. Many parts of a used elevator are not worn out and can be kept for many decades. Because there are more than three million hydraulic elevators running worldwide, replacing only the necessary ones and reusing other existing components, instead of replacing all of them, reduces the environmental impact and saves money.

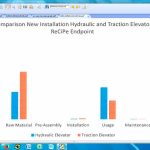

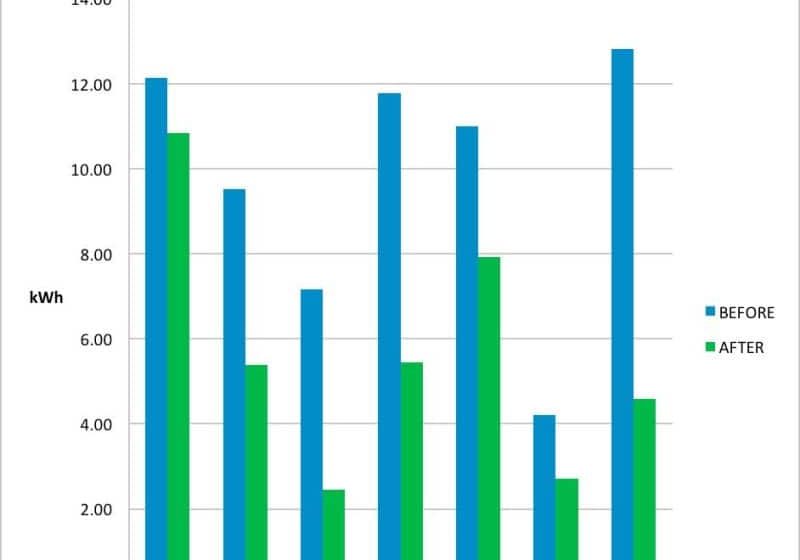

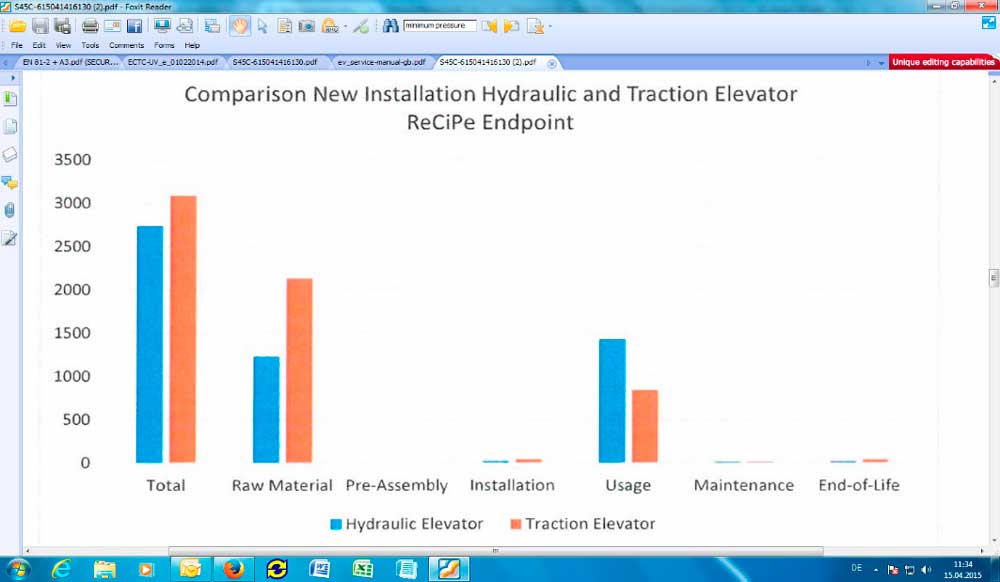

A recent study by Hydroware Elevation Technology AB of Sweden[4] on new elevator installations and modernizations for low-usage lifts (an average of 50 trips per day) clearly showed that hydraulic elevators are much more environmentally friendly than traction ones. In Figure 1, comparisons of environmental impacts for new installations (hydraulic and traction) shows that the total environmental impact for a hydraulic elevator is 7% less than that of a traction elevator. In Figure 2, environmental impacts are compared between hydraulic elevator modernization (usage category 1) and full replacement of a hydraulic elevator with a traction one. Therein, the environmental impact with the traction elevator is 43% higher. That is, modernizing a low-usage hydraulic elevator with a traction one is rather unfavorable for the environment. The study given in Figures 1 and 2 only considered the regular service visits, since there were no records of failure rates. Adding breakdowns and repairs would probably increase traction-elevator impact even more. In the LCA, when 80 years of building lifespan is used with an assumption that the elevator is modernized every 20 years, the hydraulic elevator also becomes environmentally more preferable, even in usage category 3 (300 trips per day).

In general, hydraulic elevators are much more reliable than traction elevators. Therefore, their maintenance generates much less impact. Hydraulic elevators have simple construction and fewer components, which all work in a lubricated environment. This extends the lifecycle and allows less system downtime, resulting in significant cost savings. It should be remembered that the cost of elevator maintenance is two to 10 times higher than the yearly energy consumption. In addition, the most expensive spare part of a traction MRL drive is more than 30% of the total drive cost, while this number is approximately 6% for the hydraulic elevator. In light of the above results and evaluations, when modernization is in question, full replacement of a hydraulic elevator with a traction one would be disastrous for the environment.

Energy-Efficient Systems for Hydraulic Elevators

Dealing with a more challenging market, hydraulic lift manufacturers have begun to prioritize the production of energy-efficient (new-generation) power units that employ inverters. However, utilization of the new-generation power units has not yet found sufficient appeal. This is because, while concentrating on marketing to promote state-of-the-art solutions, advantageous properties of conventional hydraulic lifts have often been ignored. By doing so, practical, reliable and low-cost ingredients of the hydraulic lift have been left, while more demanding, impractical and expensive solutions have been introduced. Thus, solutions have either become primitive, or rather complicated and costly. In many cases, a conventional power unit with the addition of a drive (inverter) is presented as state of the art. In fact, simply adding an inverter does not necessarily lead to energy savings. Moreover, employing the inverter without justifying its 95% efficiency and standby energy consumption would only increase energy bills.

Alternatively, there exist more demanding and costly solutions, which, besides the inverter, need additional components like pressure and temperature sensors, a flow meter, an encoder, an electronic control card, etc. Application of such systems, no matter how good ride quality they give and how little they vary the oil temperature, are generally away from meeting real market needs; extended payoff time (beyond the renovation period), difficulty in finding competent technicians and increased servicing needs become pronounced.

It is also believed that the most efficient equipment uses regenerative breaking to feed electric energy back into the building. However, the regenerative-drive investment for a low- to medium-usage elevator could be unwise for the environment and not able to pay back the investment during the service life. This means that the equipment used and effort spent for increasing energy efficiency will have a greater impact on the environment than what is gained by the energy-efficient system. Therefore, if the investment is not cost effective, it is unlikely to be eco friendly.

Energy-Efficient Elevator Design

Apart from energy-efficient hydraulic systems, conventional hydraulic elevators are still extensively used for the low-usage, low-rise elevator market because of substantially low cost, easy setup, simple maintenance and high reliability. If points below have been well considered, low-rise, low-usage conventional hydraulic elevators become more energy efficient than any other lift system.

- Correct elevator design: motor power size and lifting capacity

- Lightweight car and sling, or use of counterweight (CW)

- Correct power-unit size and fluid type

- Low-pressure drop in hydraulic system

- Selection of the control valve

- Correct ventilation in the machine room

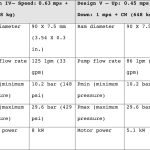

The subject can be better understood by investigating a typical 630-kg elevator (Figure 3). In Table 1, technical details of the elevator are given. Here, the dominating factors for the size of a 16.5-kW motor are car weight and elevator speed. For a six-stop elevator, a speed of 0.8 mps (157 fpm) is, in general, not usual, unless traffic is very heavy.

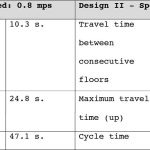

One of the first improvements in Design I is the speed, because in low-rise buildings, high elevator speed does not provide a substantial advantage for improving the traffic. When elevator speed is reduced to 0.63 mps (124 fpm), a speed of 0.8 mps does not improve the cycle time much, but reducing speed to 0.63 mps reduces the motor size 21% (Table 2).

Travel-time differences between consecutive floors and maximum up travel times are only 0.3 and 4.2 s. These times can be easily dissolved in door opening and floor waiting times, and by increasing the down travel speed. Details of Design II can be seen in Table 3.

Since down travel is managed by gravitational force in hydraulic elevators, required traffic balance can be achieved by increasing down speed (up to 1 mps [197 fpm]) and decreasing up speed without needing additional energy. In this way, motor power, size and energy consumption can be reduced considerably. This is shown in Table 3 as Design III, which reduces the motor power 44% compared to Design I.

Hydraulic elevators generally possess no CWs. This is because the CW makes the elevator system more complex, increases installation costs and removes the advantages of the elevator being simple, and easy to install and service. Other reasons for not using the CW are retaining cabin area and high levels of safety. In traction elevators, a CW is used to offset the car weight and 40-50% of the payload.

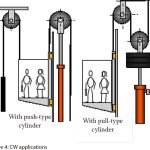

Although CWs are not preferable for use in hydraulic elevators, for the sake of reducing energy consumption, they can be used, provided that a sufficient safety level is met. In this way, the motor power size can be further reduced (Figure 4). In hydraulic elevators, weight of the CW is selected so that the minimum pressure in the system will not go below the minimum working pressure of the valve. Therefore, weight of a hydraulic elevator’s CW is always much smaller than that of a traction elevator. In Table 4, results of a hydraulic elevator with a CW is shown as Design IV. As seen in Table 4, use of a 648-kg CW reduces the ram diameter to 90 mm and motor power to 8 kW (51% less than Design I). Moreover, motor power can be reduced to 6.5 kW by using a pull-type cylinder (Figure 2). In Design V, motor power is reduced (5.1 kW) by 69% with respect to Design I by using the CW and applying traffic balance (increasing down travel speed and decreasing up travel speed).

Composite Material Usage: Carbon Fiber

Another improvement to reduce motor power is to reduce the weight of car and car frame (carrier). Use of composite materials could reduce the carrier weight by 75% by using the same volume of composite material than steel. In addition to the carrier weight, another element that influences the motor power is the weight of the ram. Ram weight could be rather large, particularly for long travel distances and heavy freight elevators. To prevent the ram from buckling, large ram diameters and thick walls are used, which increase system pressure. By using light composite material with high buckling strength, ram and the total cylinder weights could be reduced by 80-90%, smaller ram diameters can be utilized, and pump flow rates and motor power can be reduced. This situation is shown in Design VI using an 80 X 5 mm (3.1 X 0.2 in.) composite (carbon fiber) ram and 95 lpm (25 gpm) pump (Table 5).

The first prototype of a hydraulic carbon-fiber cylinder developed by Blain Hydraulics is shown in Figure 5. The objective of the work is to offer the sector a lightweight cylinder with improved mechanical properties. It is possible that critical buckling length of composite pipes can be increased twice or more by using appropriate resins and correct manufacturing techniques. This will result in hydraulic elevators to be used, even in mid-rise buildings, without the need of utilizing heavy and large-diameter cylinders.

Design VI shows that utilization of composite (carbon fiber) carrier and cylinder (without employing a CW) could reduce motor power by 58% (Table 5). In addition to Design VI, applying traffic balancing (Design VII) reduces the motor size further, to 5 kW. These results show positive contributions of composite-material usage; that is, 70% of reduction in motor power without using a CW and downsizing energy consumption to a traction MRL elevator level.

A New-Generation Control Valve

There can be many ways to engage a control valve with an inverter to obtain a new-generation valve. The most important question is how to offer an inexpensive and simple solution with good ride quality. Knowing the market needs and evaluating truly necessary requirements, Blain and Yaskawa EU developed a new-generation control valve, EV4-vvvf (Figure 6). It is a hybrid solution that uses the inverter only for up travels and, therefore, offers the most energy-efficient and inexpensive solution. It has no interfaces with its peripheral devices and does not require sensors for load compensation. Since the up travel is controlled by the inverter, up solenoids and adjustments were removed from the valve, which considerably simplifies both the valve and system setup. To lower the initial cost and simplify the system requirements further, open-loop control has been implemented. Thus, the need for a costly submersible motor encoder or an encoder in the hoist was eliminated. All these improvements allow two to four years’ payback durations over 50 cycles per day. The real benefit of the system comes from the exclusive L1000H Yaskawa inverter software, which eases the use of the system, provides positive travel characteristics and prioritizes energy consumption.[5]

Depending on elevator usage, the EV4-vvvf can provide energy savings of up to 65%. This is because fluid bypass no longer occurs, travel time is shortened and motor starting current is no longer high. Because of that, EV4-vvvf reduces temperature increase by 50% and allows the system to be operated at high elevator usages without the problem of oil heating.

Hydraulic elevators made of composite material and using EV4-vvvf can reduce energy consumption 70-80% with respect to Design I. In Table 6, equivalent motor powers are given for the Designs I, II, III and IV in case 50% of energy savings is obtained by EV4-vvvf.

Conclusions

The perception that has been created against hydraulic elevators being inefficient and environmentally dangerous does not reflect reality. CWs are normally not used for hydraulic elevators, because they make the elevator system more complex, increase installation cost and remove advantages of hydraulic elevators being simple, and easy to install and service. On the other hand, the CW and other design methods could be utilized to lower energy consumption to the traction MRL elevators’ level. To reduce the power level from 16.5 kW to the equivalent power level of 3 kW, using different means like CWs, balancing the elevator traffic, utilizing composite materials and energy-efficient hydraulic valve systems are shown. Moreover, it is underlined that, when 20-year modernization intervals are considered, environmental performance of low-usage hydraulic elevators is much better than that of traction elevators.

For an alternative to the CW, the composite cylinder, which increases the buckling strength twice or more, can be used. In that way, hydraulic-elevator service height can be increased up to 40 m. At present, composite cylinders are costly and can only be affordable for special applications. However, innovative developments in composite technology are progressing rapidly, and it is expected that in the near future, composite carriers and cylinders will be employed more by the hydraulic-elevator industry.

- Figure 1: Impact assessments of hydraulic and traction elevators for new installations

- Figure 2: Impact assessments between hydraulic modernization and full replacement with traction elevators

- Figure 3: Indirect hydraulic elevator

- Figure 4: CW applications

- Figure 5: Carbon-fiber cylinder by Blain Hydraulics

- Figure 6: EV4-vvvf open-loop control solution

- Table 1: Details of elevator data and Design I

- Table 2: Comparison of travel times for 0.8 mps (157 fpm) and 0.63 mps (124 fpm) elevator speeds

- Table 3: Designs II and III

- Table 4: Comparison between Design IV and Design V

- Table 5: Comparison between Design VI and Design VII

- Table 6: Energy consumptions and equivalent motor powers when an EV4-vvvf solution with 50% savings is used

References

[1] Almeida, A.T. “Energy Efficiency of Elevators & Escalators,” 4th European Lift Congress (2010).

[2] Celik, K.F. “Stand-By Energy Consumption on Low Usage Lifts,” ELEVATOR WORLD India, Vol. 2 (3rd Quarter 2009), p.58.

[3] Nipkow, J. “Elektrizitätsverbrauch und Einspar-Potenziale bei Aufzügen,” S.A.F.E. (2005).

[4] www.hydroware.de/lib/get/file.php?id=155f9221554af7

[5] Celik, K.F. “Design and Control of Electronic Elevator Valves,” Elevator Technology 17: Proceedings of Elevcon 2008 (2008), p.34-45.

Get more of Elevator World. Sign up for our free e-newsletter.