Elevator Enclosures and Cars

Aug 1, 2011

A look back at the use of iron in the design and construction of early elevator cars and systems.

In 1899, the International Textbook Co. (the publishing division of the International Correspondence Schools) published a new book titled Ornamental Ironwork. The topic was introduced as follows: “Iron is used in building construction to serve two purposes, one structural and the other ornamental; but [it] becomes an element of architectural consideration only when both purposes are combined.” Thus, the unknown author of this book attempted to distinguish be-tween the use of iron for structural or engineering purposes, which had no aesthetic value, and the use of iron as applied ornament or decoration, which had no connection to the true nature of the material. The author believed that the best approach was to “develop a system or scheme of design which will be consistent with the conditions imposed by the material and its structural use.” This statement derives, in part, from 19th century discussions concerning the idea of what constituted “modern” design and the need to “truthfully” use materials according to their inherent characteristics and qualities.

The subjects addressed in the book included wrought-iron work, cast-iron work, forged work, cast-iron stairs, office grilles, leaves and foliated work, gates and fences, window guards, lamps and brackets, iron structures, and elevator enclosures and cars. The author focused on the fundamentals of design and construction, with special attention paid to normative shop practices. The latter emphasis resulted in the majority of the illustrations being derived from actual working drawings that had “been used in the preparation of iron-work for some of the most important buildings.” While, unfortunately, the specific “important buildings” were not identified, the presence of multiple pages of late 19th century working drawings of elevator enclosures and cars constitutes a unique historical record, which, in this context, focused on open ironwork or “bird-cage” elevator cars and open shaft enclosures.

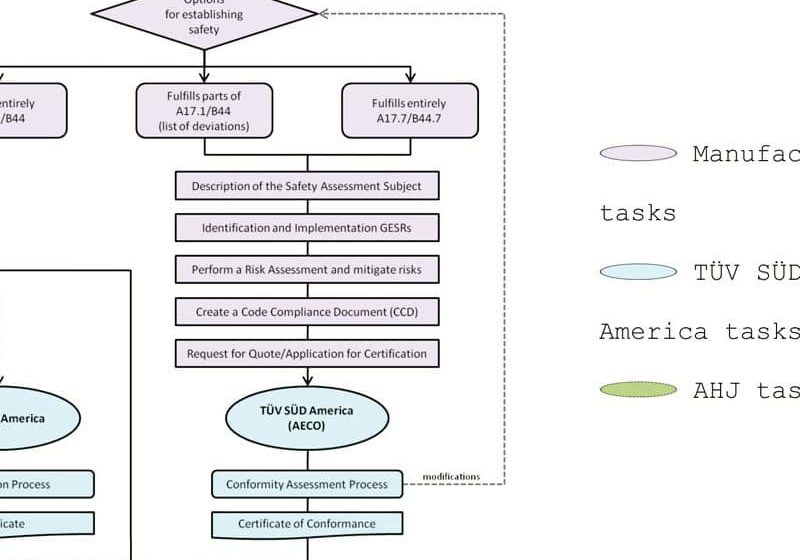

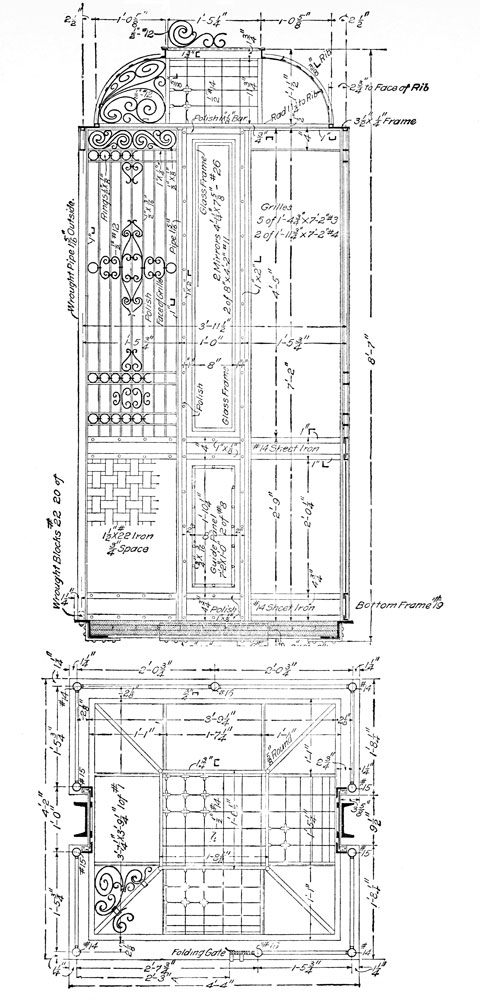

The section titled “Elevator Enclosures” provided de-tailed descriptions of two different hallway shaft enclosures: one primarily composed of cast iron and the other of wrought iron. While in each instance the text was sup-ported by numerous drawings – ranging from details to sections to elevations – the set produced for the cast-iron enclosure offered the most thorough explanation of these systems. The author first described the construction of the decorative grille work for the shaft enclosure and then described the construction of the shaft door and how it was integrated into the overall design. The nature of his presentation is revealed in the following introductory remarks:

“The shaft is formed by the main wall of the building in the rear, and fireproof partitions on the sides, the front only being of grille-work. An angle iron or a channel is usually set across the front of the wall at each floor … the top of which is generally 4 in. below the level of the finished floor of the story above, although the location of these beams, being a matter that is determined in connection with the general structural framework of the building, varies materially in different structures. The enclosure work must, of course, be made to suit the positions of these beams on which it is supported, and the important point is their relation to the finished floor level. In fact, the principal measurements necessary to lay out the work are the width between the partitions, the distance from the finished floor to the top of the beams, the depth of the beams, and the height from floor to floor (which will generally be the same as from beam to beam).”

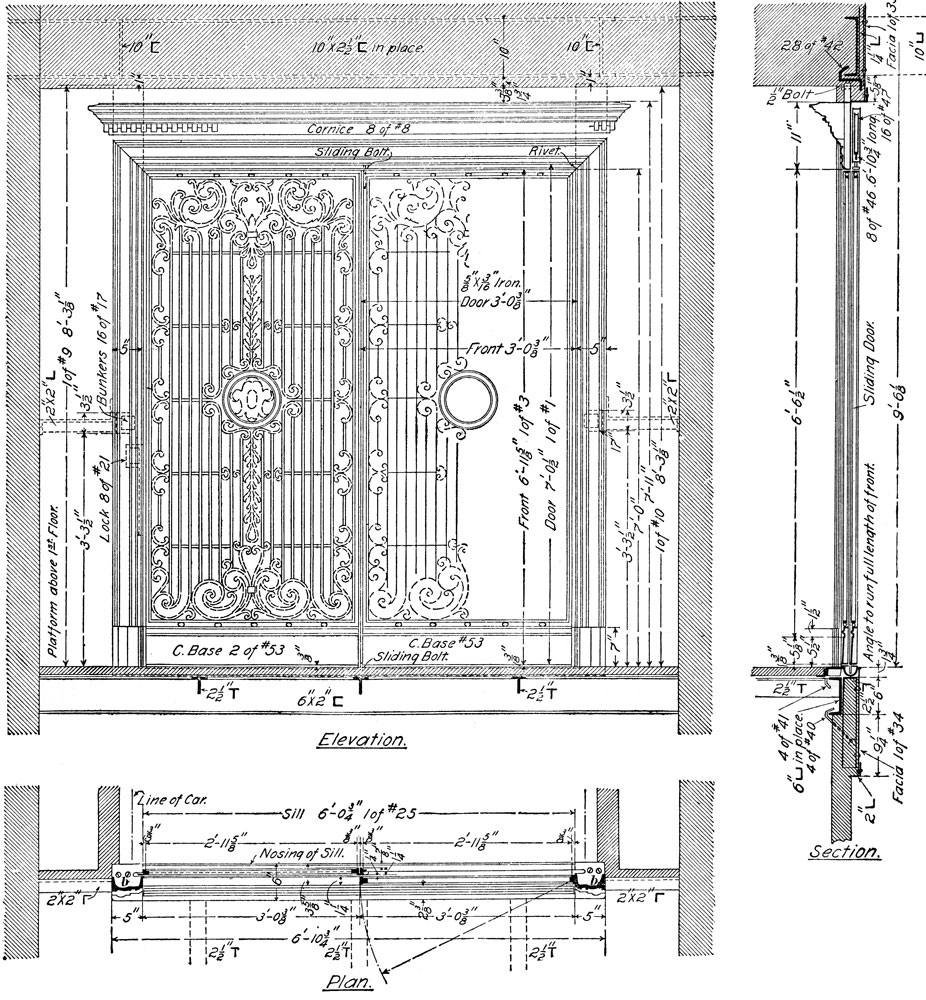

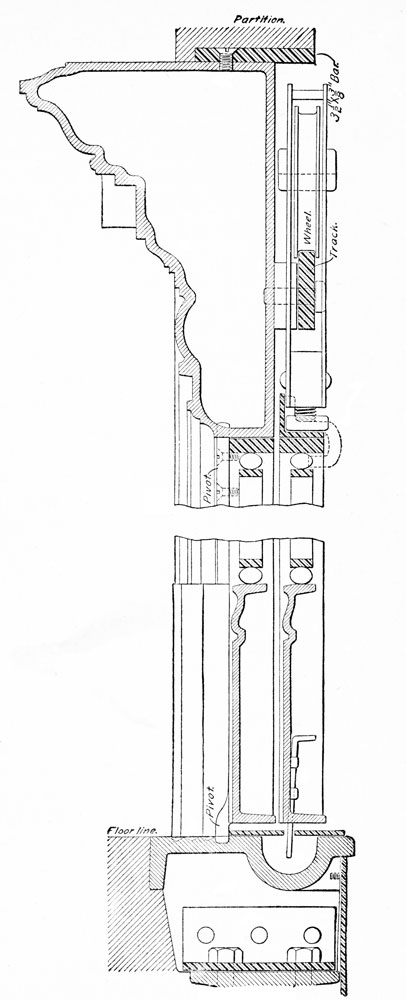

The primary drawings that illustrated the grille-work installation included a combined elevation and section of the grille front, a vertical section, and a plan. Additional images included a detailed drawing of the entry sill and cornice, and a detailed drawing of the shaft door opening.

The shaft opening was fitted with a fixed panel and a sliding door, each of which were 3-ft. wide and employed the same decorative grille-work pattern. The sliding panel was apparently operated by hand, as no automatic-door mechanism was present in the drawings. However, a close reading of the plan reveals a dotted line and arc that resembles the typical plan indication reserved for hinged-swinging doors. Its presence reflects a unique characteristic of these types of installations. Under nor-mal operating conditions, the entrance to the car was restricted to the 3-ft.-wide opening defined by the sliding door. However, if the elevator was needed to transport larger items, the sliding door – which passed behind the fixed panel – could be released so that it passed completely behind its fixed counterpart, which, in turn, could be released so that it and the sliding door could be swung open as a single unit, thus providing an approximately 6–ft.-wide opening into the elevator shaft. The detailed drawing of the entry sill and cornice also revealed that the sill plate featured V-shaped “angular grooves” because they gave “a better foothold than if the surface were smooth.”

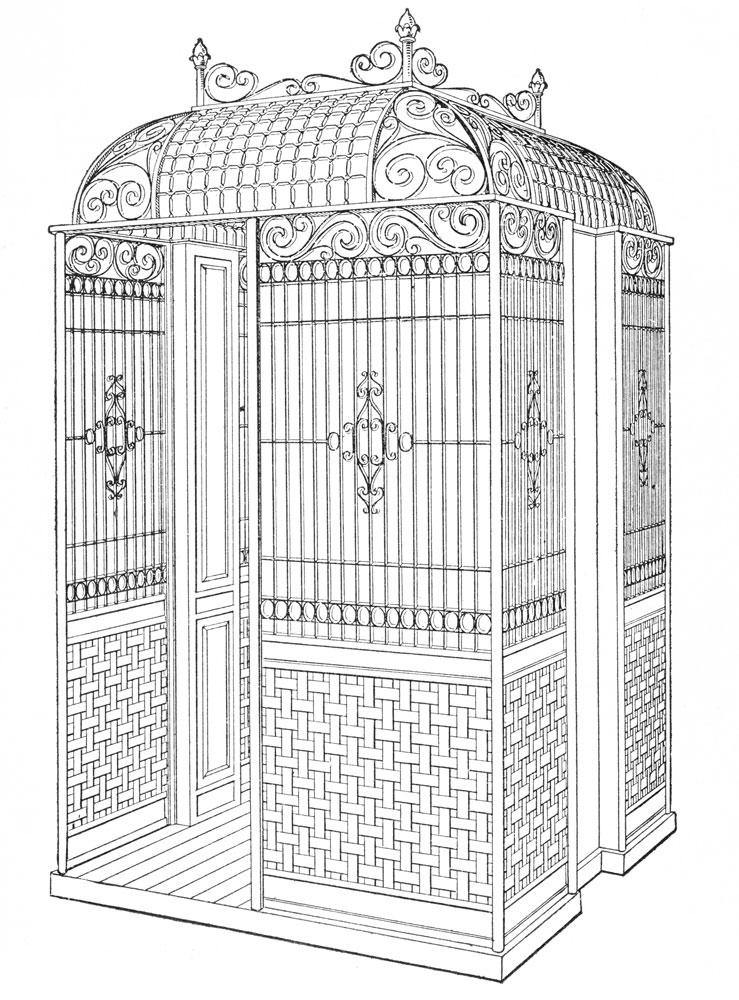

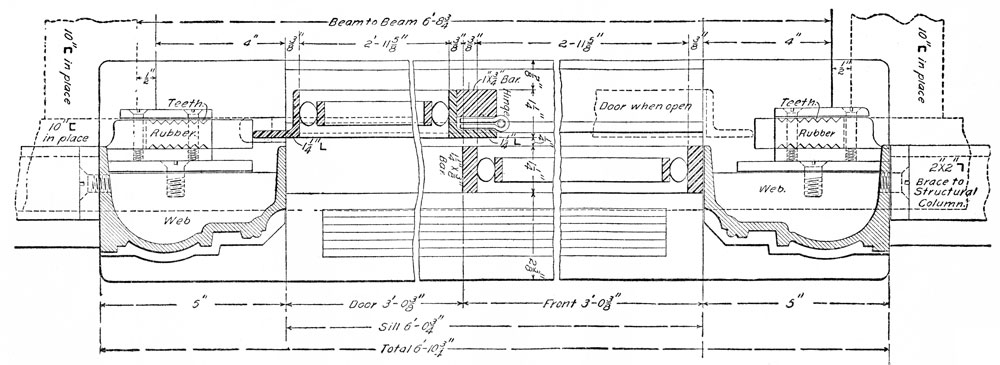

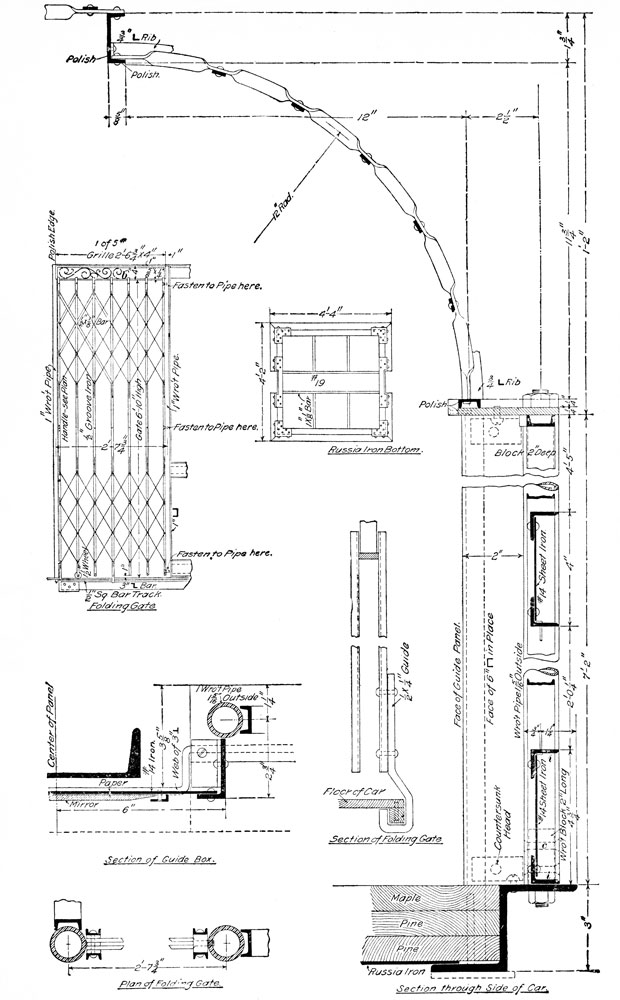

The section titled “Elevator Cars” provided equally de-tailed descriptions of two elevator cars, one of which was described as “simple and inexpensive, while the construction is substantial and serviceable,” and the other was simply described as a “more elaborate” design. The author observed that elevator cars were “usually con-structed of angle-iron or pipe framework and filled in with woven-basket and twisted iron grille-work and scrollwork.” The result was an open birdcage car-type, which was often illustrated by perspective drawings that highlighted the car’s transparency. In fact, the book contained this typical image, which, in this case, depicted the “simple and inexpensive” car design. Of course, in this context, the image was also accompanied by detailed drawings that explained how the car came into being. These drawings included a vertical section through the car, a combined horizontal section, roof plan and a sheet filled with various construction details.

The car frame was composed of wrought iron pipes, which were fitted with small channels that received the grille-work that made up the car walls. The guides, visible in the interior as shallow, rectangular projections, also offered a design opportunity. Each rectangular projection featured a base composed of sheet-iron dado panels (2 ft., 9 in. high), with the remainder of the surface covered by beveled plate-glass mirrors. The roof grille was composed of short pieces of “simple twisted strap iron.” The floor of the car was composed of three layers of wood: two base layers of pine topped by a finish layer of maple. The thick, wooden floor was held in place by 3-in. Z bars and a “Russia-iron” shield that rested on the bars’ bottom flanges (the phrase Russia-iron referred to special iron sheeting that was highly resistant to rust). The car was equipped with a “sliding or folding gate” door that permitted a narrow 2 ft., 7.75 in. opening into the car. Interestingly, the description of the car does not include a discussion of how this narrow opening corresponded to the ability to increase the width of the shaft opening when needed.

Ornamental Ironwork includes a wealth of additional construction details about elevator enclosures and cars. This information both expands our understanding of elevator history and constitutes a resource that might be useful to professionals engaged in the preservation or rehabilitation of late 19th or early 20th century elevators. This material also serves as a reminder of the complex nature of elevator construction and operation, which had always been a constant feature of vertical transportation technology.

Plan, section and elevation of cast-iron enclosure, Ornamental Ironwork, International Textbook Company (1899)

Detailed drawing of door sill and cornice for cast-iron enclosure, Ornamental Ironwork, International Textbook Company (1899)

Vertical section and combined horizontal section and roof plan of elevator car, Ornamental Ironwork, International Textbook Company (1899)

Elevator car construction details, Ornamental Ironwork, International Textbook Company (1899)

Detailed drawing of entrance cornice for cast-iron enclosure, Ornamental Ironwork, International Textbook Company (1899)

Get more of Elevator World. Sign up for our free e-newsletter.