Elevator Modernization

Mar 1, 2015

Stuffing 2,500 lb. of elevator into a 1,500-lb. shaft

In today’s elevator-industry vernacular, the term “modernization” can be taken a number of ways. Immediately apparent to the eye – and relatively easy on the budget – is an upgrade of cab and entrance aesthetics, which, for property owners, delivers a number of positives. Compelling new lobby and cab designs can add significant value to the property, help owners and managers compete with recently constructed buildings for new tenants, encourage the retention of current occupants and make the ride much more enjoyable for their visitors, the day-to-day passengers. Such upgrades can also help make a property become “greener” and qualify for Leadership in Energy & Environmental Design points. But, as it relates to elevators, the term “modernization” has implications far beyond the aesthetic and environmental, notably in the areas of functionality, safety and code compliance. While many updates are elective and optional, some may be required, depending on conditions.

L.J. Blaiotta, Jr., president of Columbia Elevator Products, explains:

“For example, legacy equipment may fall victim to age and cease to be viable. The equipment may not be compliant with the Americans with Disabilities Act (ADA) and/or current code. Replacement parts may be difficult – if not impossible – to obtain. Car calls may become unacceptably slow, and passenger convenience, not to mention safety, may be at risk. In these situations, updated equipment actually may be mandated by current safety standards and compliance with federal, state and local codes.”

Beyond the simply cosmetic, intermediate modification efforts were targeted toward improving the service of the elevator, including upgrade from manually operated to power-operated doors, new car-operating panels (COPs) and other evolutionary developments. “But,” says Lou Blaiotta, Sr., Columbia’s founder and chairman, “here we will focus on full modification, involving replacement of the entire elevator system, including the drive equipment, reusing only the existing hoistway and rails.”

According to Blaiotta, Sr., ideal candidates for such full modernizations are the single-speed AC traction elevators, of which many thousands remain in operation today (10,000 in New York City alone). Emerging in popularity during the post-World War II period, these were installed as upgrades of earlier, prevalent DC systems when the municipal trolley grids by which they were powered were converted to AC.

As Blaiotta, Sr. explains:

“With the return home of massive numbers of military personnel, an urgent need developed for housing this instantly expanded population and the growing families. Suburban development exploded, and inner cities saw the conversion of tenement walkups to four-to-six-story apartment buildings and the new construction of high-rise developments. Municipalities hurriedly legislated and approved semi-fireproof construction of these buildings, provided they included secondary avenues of egress, such as fire-rated stairs and the fire escapes that came to visually emblemize the cities of the time. To encourage such construction, municipalities provided financial incentives, including low-interest loans, extended mortgage terms, power-rate concessions and federal/state tax deductibles – an example of all this was the Mitchell-Lama Law in New York State, with similar programs implemented elsewhere.”

Having been in place for 50 or more years, many of these remaining AC traction systems are not code compliant, frequently out of service, constantly in need of expensive repairs and, generally, a bane to landlords and their severely inconvenienced tenants. Many of these elevators may have been subject to partial modernizations – replacement here and there of machines, doors, interlocks, controllers and fixtures updates – but remain lacking in the fundamental areas of safety, accessibility and code compliance. Many older structures did not have the available square footage to allow for installation of an ADA-compliant cab (sufficiently large to accommodate a stretcher, etc.), presenting a severe obstacle to operating a viable building in today’s environment. This created the need to develop a much more far-reaching level of upgrade – a way to install larger-platform cabs in existing, limited-size hoistways. Since it was not possible to enlarge the car by making it wider, this left only the option of making it deeper from front to back.

Blaiotta, Sr. explains:

“At Columbia, we innovated a number of ways to accomplish this. For openers, on the front end, we moved the sliding doors into the wall, Columbia’s so-called ‘InWall pocket-door solution,’ to free up several inches of space. We used linear operators, such as our ALURE® system, to offset the doors and position them directly at the edge of the sill for a savings of 2 in. or so of clutch space. But, the major space savings was achieved by replacing the AC traction system with hydraulically operated pistons positioned at the sides of the car in the space already occupied by the rails, thereby eliminating the counterweight and cables behind the car. This 10 in. of saved space, combined with the space saved by our overhead car front and InWall doors, allows for a cab that is 15 in. deeper or more, ADA compliant, higher weight rated, able to carry more passengers and better able to serve the building.”

With Elevator Equipment Corp. (EECO) as its fabricating partner, Columbia developed a breakthrough solution based on certain realities. In new construction, when starting from scratch, a single jack in its entirety can simply be planted in the ground. But, in existing, older buildings, for many reasons, one would rather not be digging holes, meaning that a “hole-less” solution needed to be found. One such method was to mount a telescopic piston structure that expanded upward, similar in appearance to classic automobile antennas, at ground level. But, in buildings four to six stories tall, the overall height of the hoistway would most likely have to increase. The ultimate answer was a dual-roped hydraulic system that overcame these negatives.

As Daryl Frith, national sales manager of EECO, explains:

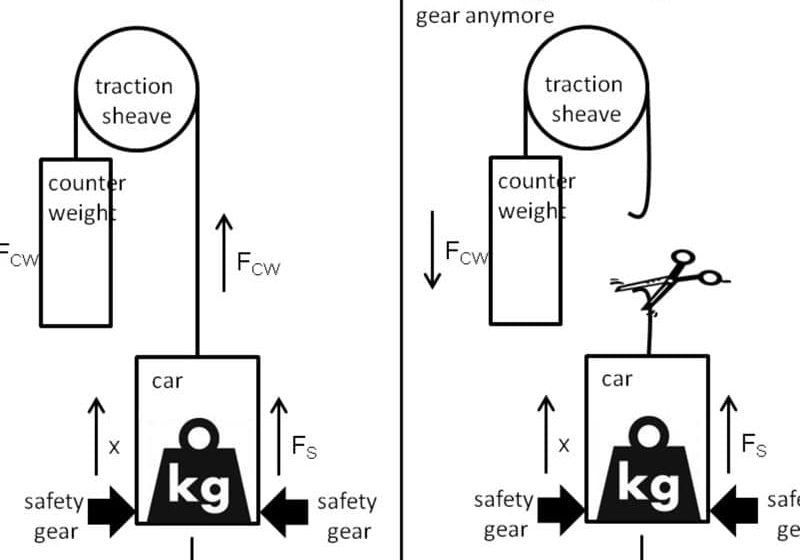

“Instead of pushing the car up from beneath, each of the two (much smaller) pistons push up a sheave assembly traveling atop the moving piston, with a wire rope configuration that allows the elevator to move at a 1:2 ratio. Each of the multiple wire ropes (per side) runs through one of the sheave’s grooves and is anchored at one end to the hitch plate on the jack cylinder and, on the other end, to the bolster assembly beneath the car. So, for every 1 in. the piston pushes its sheave upward, the result is 2 in. of upward travel of the car, in a very power-efficient manner. And, the pistons/jacks reside in the preexisting 8-10 in. space on each side of the car, adjacent to the rails, consuming no additional space of their own, thereby allowing for a larger platform. To summarize – by utilizing an existing fireproof hoistway, removing the overhead or basement AC traction machine and its counterweight assemblies, removing existing swing doors and installing InWall pocket doors and an overhead car front, relocating the 4-in.-deep COP from the front return panel to the side wall to protrude into the existing rail space and installing a dual-roped hydraulic system and enlarging the platform. The result is a larger, fully automatic, handicapped-accessible elevator. Capacity is increased from 1500-1800 lb. to 2100-2500 lb. – effectively, a conversion from limited-use/limited-application-sized to full sized.”

The upsides of such full modernizations are many. From an ecological point of view, installing oil-operated jacks in the ground is avoided. Roofs, which must be opened for the project, can, in the process of reconstruction, be fashioned into green, hangout spaces, taking advantage of the additional area made available by elimination of the penthouse machine room. For tenants, it means a better, more contemporary building, less inconvenience due to elevator downtime; a faster, smoother ride devoid of flying stops; and not needing to consider moving to a newer, more expensive property.

For building owners, the advantages represent significant economic value. “Roped hydro systems are much more energy efficient than traction,” explains Blaiotta, Sr., continuing:

“Cranes can be shorter, and crane rental time is reduced by the easy drop-in of the jacks through the hole created by reducing the size of the rooftop machine room. Financial institutions are more willing to fund such major upgrades, as opposed to smaller cosmetic projects, especially in light of consequently available rent increases under rent-control guidelines and more profitable operation enabled by tax depreciation allowances and interest payment deductibles.”

“Bottom line,” concludes Blaiotta, Jr., “such modernizations are a win/win/win all around – for those who own the buildings, those who inhabit them and for us all sharing the environment. And, for the owners, the economic benefits can be such that it literally pays to be modern!”

Get more of Elevator World. Sign up for our free e-newsletter.