Elevator Noise Tester

Jun 1, 2014

A flexible device to measure elevator noise is based on virtual instrument (VI).

by Yihui Ruan, Ning Li, Xueming Chen, Jiefeng Li and Weitian Qiu

Noise is an important influence on people’s health. Due to elevators being necessary building components in many modern buildings, many of its factors deserve consideration. Elevator systems can produce irritating noise from only the cabling system and motor, particularly when the car is at an upper floor near the engine room when close to the main traction machine. Many units use electrical contact switches to control elevator operation. These switches are generally housed in a rack within the machine room and can generate significant impulsive noise as they engage and disengage. This noise often stands out from general ambient noise due to its impulsivity. The operation of elevator doors can also generate sound.

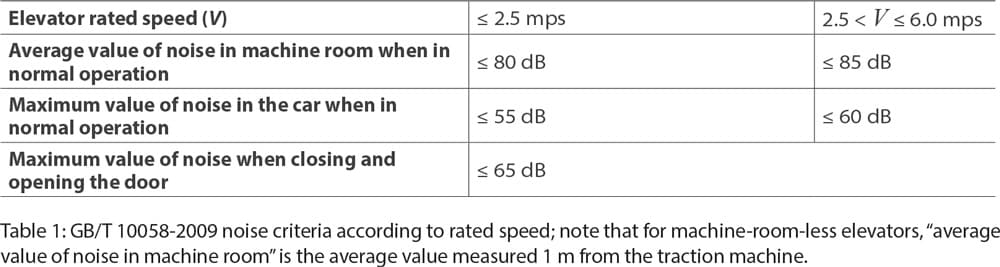

It is harmful to people’s health when value of the noise exceeds 40 dB. In China, the recommendatory standard GB/T 10058-2009 — Specification for Electric Lifts stipulates noise values when freight or passenger elevators are in operation (Table 1). The method described in this article can accurately measure elevator noise in real time. A laptop containing a proper inner sound card, inner microphone and LabVIEW software can accomplish this. The inner microphone is attached to the sound card, which can replace the data-acquisition card in some VIs. The instrument this paper introduces makes the operation more convenient with a friendly human/machine interface.

The Principle of the Tester

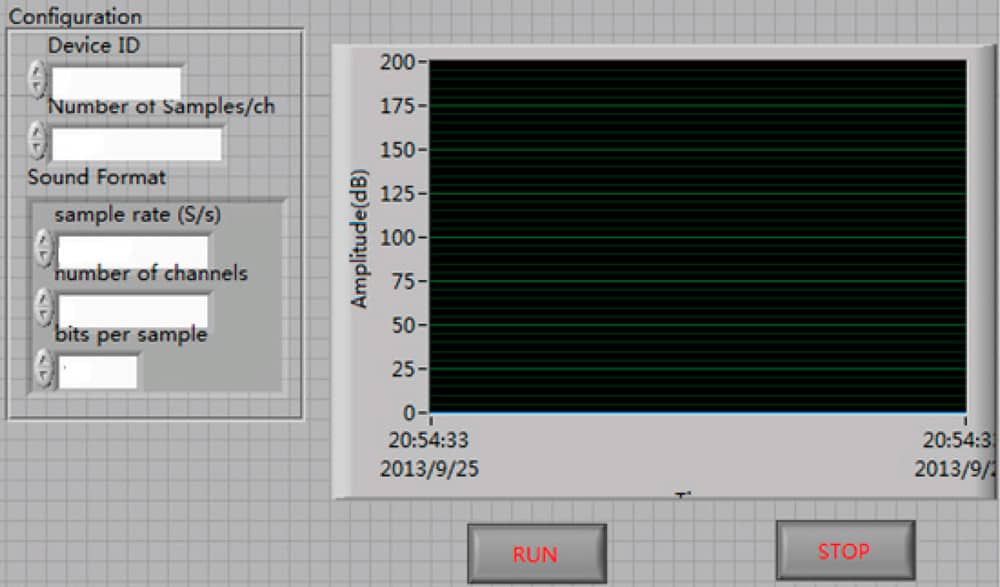

The tester’s sound card can convert analog audio signals (microphone, instrument or turntable outputs) into digital audio computers can understand. This allows the recording of audio on a computer using recording software, which can be divided into two modules: data acquisition and signal analysis. Outer sound can be received by the inner microphone connected to the sound card. Then, it is transmitted to the sound card. The sound value can be recorded as a waveform graph in LabVIEW (Figure 1) in real time. Data acquisition has three steps: initialization/sound-card configuration, acquisition and sound-card release.

LabVIEW is a graphical programming environment used to develop measurements, tests and control systems using intuitive graphical icons and flowcharts. It offers integration with thousands of hardware devices and provides hundreds of built-in libraries for advanced analysis and data visualization for creating virtual instrumentation.

The following are instructions on how to execute the VI:

Specify “Device ID,” “Number of Samples/ch” and “Sound Format.”

Run the VI.

The VI will continuously acquire samples and plots the raw data to the graph.

Conclusion

The tester makes use of a powerful VI based on the internal sound card to acquire the noise signals in real time, and they are recorded and saved in the tester per time. No other additional instruments are required, so the tester is easily transportable. It has a wide application prospect.

Get more of Elevator World. Sign up for our free e-newsletter.