Elevator Shaft Connections

Oct 1, 2014

Your author examines which anchors are appropriate, as well as how they are selected, engineered and evaluated for safety.

In a fast-paced commercial environment, elevator companies have the challenging job of achieving long-term safety for their clients. Even under commercial pressure, safety often comes down to paying attention to both the major and less-conspicuous components and processes. Connection systems used in the elevator shaft may be seen by some as falling into the latter category.

During new installations and maintenance, both drilled and cast-in-concrete connection systems are used to secure equipment to shaft structures. On the supply side, a variety of fastener manufacturers offer a wide range of products with varying levels of performance and quality. So, some care has to be taken to ensure that products with appropriate performance and reliability are used. This is particularly the case for situations where reliable performance is an absolute must for long-term safety. Some of the most important of these connections are also subjected to dynamic loading. These include connections for elevator guide rails, divider beams and doors.

Dynamic Loading

Dynamic loads rapidly oscillate between higher and lower levels. This is in contrast to static loads, where the loading level remains constant. The rapid cyclical nature of dynamic loading is very hard on materials and, over time, can induce fatigue and eventual failure. Fatigue is induced faster as the cyclical load variation and number of cycles increases.

Over the lifetime of an elevator, connections for guide rails, divider beams and doors can be subject to dynamic loading over millions of cycles. This means that, in order to avoid premature anchorage failure, care must be taken to ensure the connections used for these components are suitable for dynamic loading over the elevator’s anticipated lifetime.

Anchor Channel Types

In general, better long-term dynamic loading performance is achieved with materials offering higher ductility. This means the manufacturing process of formed-steel shapes, such as the cast-in anchor channels used for elevator shaft connections, is critical to the long-term, dynamic performance of the connection. If anchor channels are cold formed, the area of material in the region where the profile bends becomes work hardened and more brittle. This is normally fine for static loading conditions, but in the case of dynamic loading, it can promote early fatigue in the material.

Hot rolling produces anchor channels with a much more ductile material. Much of the in-built stress and accompanying brittle features of cold-rolled channels are not present in hot-rolled alternatives. Consequently, safer long-term dynamic-loading performance for critical elevator shaft connections is achieved using hot-rolled anchor channels. So, selecting connections in the elevator shaft is not just a matter of checking the static load performance of the connection. Normally, the design data of an anchor manufacturer will have to be checked to establish if the tested design life of the connection meets expected dynamic conditions.

In the last few years, hot-rolled anchor channels with serrated lips have been developed to transform the design load capacity of anchor channels when loaded longitudinally in the direction of the opening in the channel. This can be particularly interesting to elevator designers who want to use adjustable connections that also accommodate high side loads applied to the elevator rail. Such load conditions are a common situation in designing for earthquakes. In these conditions, the counterweight rail, in particular, can encounter very high side loads. Quite often, counterweight derailments occur during major seismic events, and the resulting damage to the shaft, car and equipment can be considerable.

Cracked Concrete

Research has shown that, in certain conditions, flexure is induced in structural concrete components, causing microcracks in the concrete. As a result, modern designs typically take into account the possibility of cracked concrete. Concrete cracks in the vicinity of the anchor will cause a weakening of the connection. The behavior of anchors in cracked concrete is largely dependent on the anchorage depth and head design. Typically, anchors with small head diameters will not perform as well as those with larger heads. Accounting for cracked concrete should be included in the anchor manufacturer’s design information.

Obviously, the anchorage condition can become more severe when wide cracks develop in the concrete as a result of flexure caused by severe seismic activity. One outcome of seismic testing for anchorage in safety-critical areas has been the development of special, long anchors with large head areas for hot-rolled, toothed anchor channels. These resulted from testing anchor channels positioned directly over wide cracks in the concrete. After preloading the anchor channels, additional cyclic loads were applied in tension and shear to simulate loading during a seismic event. Depending on the type of building and its location, elevator engineers may also need to accommodate severely cracked concrete in anchorage design.

Anchoring to Other Material

The range of anchoring conditions faced by installation crews and designers varies widely. Connections to conventional concrete shafts may be needed. In other situations, anchorages to heavily reinforced, high-strength concrete shafts are required, particularly on tall or seismically designed structures. On other structures, the shaft wall may be made of concrete masonry units (CMUs) or brick. In some cases, elevator shaft connections have to be affixed to structural steel or a secondary steel framework.

Connections to brick and CMU are a frequent problem. Although much progress has been made in drilled connection technology, the brick or CMU material is normally the weak point in the connection, particularly when loaded dynamically. Attempts to fill the voids of CMUs with concrete to improve performance often have variable results. Due to material and workmanship variations, anchorage performance can be unpredictable, so this type of connection is difficult to engineer.

With some predesign by the building’s structural engineer, a more reliable connection method can be introduced on new shafts by using concrete beams at the locations of the guide-rail brackets, divider beams and door connections. Beam positions are relatively easy to establish at the design stage, because, for a given specification of elevator, anchorage locations for most bidding elevator companies should be similar. Within the concrete beams, cast-in, hot-rolled anchor channels are used to provide a reliable, fast and adjustable method of anchoring to the masonry wall by the elevator installation team.

Hot-rolled channel profiles can be similarly useful as part of a connection system to structural or secondary steel. In this application, channels are used without the additional anchors needed for connections to concrete. The raw profiles are simply welded to the steel structure, then protected from corrosion with a post-applied finish. Again, this method is best preplanned at the design stage and factory welded to minimize welding on the construction site.

The material properties of the channels make hot-rolled profiles ideal for welding, and, combined with twist-in T-bolts, produce a reliable and versatile connection method for doors and guide-rail brackets. Connections between divider beams and guide rail brackets are an ideal application for this sort of product.

Attaching to Concrete

In addition to engineering performance, price, and ease of use, consideration for the safety of the installation crew is also an issue when selecting a connection system. There are three basic methods for attaching to concrete:

- Drilling holes for either resin anchors or expansion bolts

- Welding to embedded steel plates

- Bolting to anchor channels cast into the concrete.

These methods have not only different technical and practical aspects governing their use, but also accompanying workforce-safety issues. Drilled bolts are often used in the elevator shaft for equipment and guide-rail connections. They can be deceptively simple in concept and perceived convenience. However, this method has some safety issues and practical problems. In addition to possible damage to concrete and structural reinforcement, drilling produces noise and dust, which research has shown to result in health safety risks. Exposure to silica dust and high noise levels associated with drilling are now well understood to be health risks in the industry, particularly in confined spaces, such as elevator shafts.

Less well publicized in the U.S. are the health risks to installation teams associated with prolonged exposure to vibrating hand tools, such as hammer drills. Hand/arm vibration syndrome (HAVS) or “white finger” is a progressively debilitating condition that can affect long-term users of power tools. Based on an increasing body of research over recent years, HAVS has already been the subject of legislation in Europe, establishing daily limits on construction workers’ exposure to power-tool vibration. In the U.S., there is no legislation yet. However, research on HAVS is internationally recognized, and safety recommendations from some North American agencies are starting to provide guidance on this issue that generally follows the European position.

Onsite welding to steel components or steel plates embedded in the concrete walls of the elevator shaft also has to be closely monitored for safety. Welding fumes, very high heat, sparks, intense ultraviolet light and the possibility of electrocution are all health and safety concerns. Over time, accidents are likely with welding processes, unless they are in a controlled factory environment.

By contrast, cast-in channel anchoring systems are easy for installation crews to manage from a health and safety perspective. Connections are made to channels previously cast into the concrete using twist-in T-bolts, with nuts that can be tightened with a simple wrench. No power tools are needed. No drilling or welding is required, so risks to the health and safety of installers are much reduced.

Current applicable design codes for cast-in anchor channel connections are the 2012, 2009, and 2006 International Building Code® (IBC); the 2012, 2009 and 2006 International Residential Code® (IRC): American Concrete Institute International (ACI) 318 Appendix D; and the newly developed ICC-ES Acceptance Criteria for Anchor Channels in Concrete Elements (AC232).

The first cast-in anchor channel product evaluation report in North America was issued for JORDAHL® anchor channels in 2013 based on AC232, and the IBC, IRC and ACI codes by the International Association of Plumbing and Mechanical Officials (IAPMO) organization (IAPMO Uniform ES Report #0293). Further product evaluation criteria for anchor channels are being developed by the ICC and are expected to be completed in the near future.

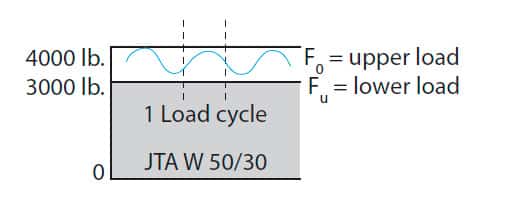

A dynamic load cycle varying by 1,000 lb. acting on a connection to a cast-in, hot-rolled anchor channel

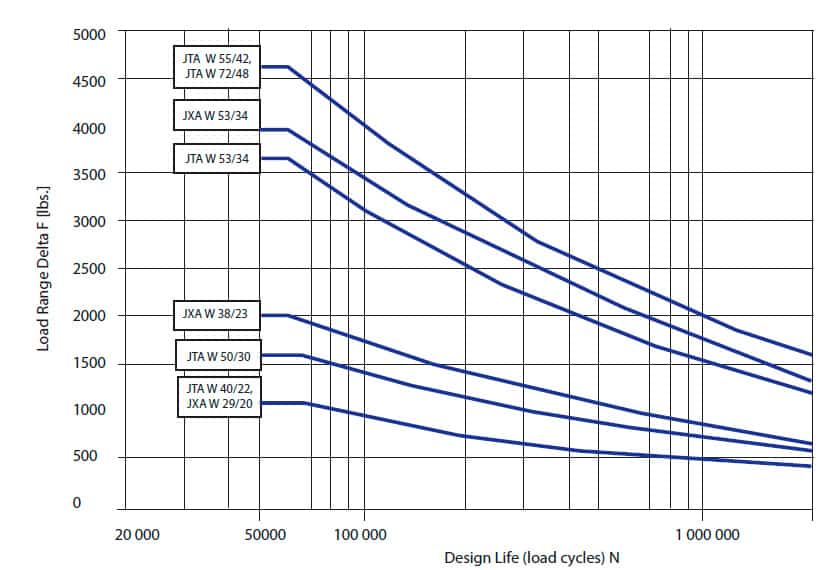

Dynamic loading graph for a range of JORDAHL hot-rolled anchor channels showing permissible load variations according to the number of load cycles over the design life.

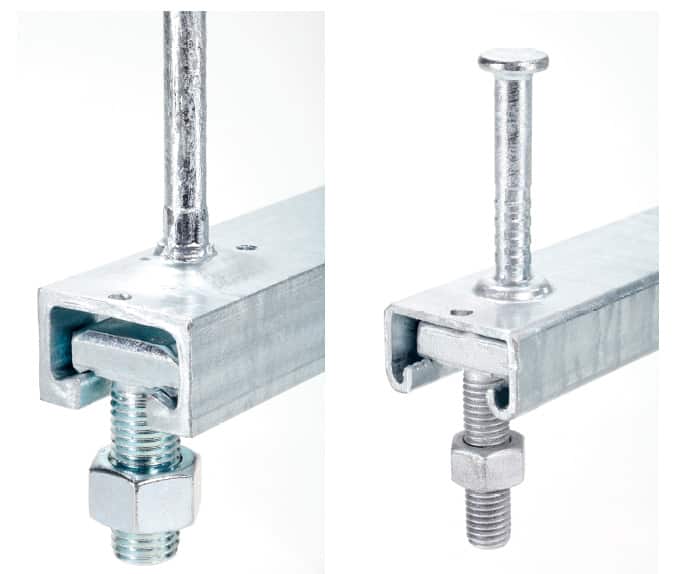

The hot-rolled, cast-in anchor channel on the left is recognizable by distinctive square exterior corners, while the cold-formed profile on the right has large-radius bends.

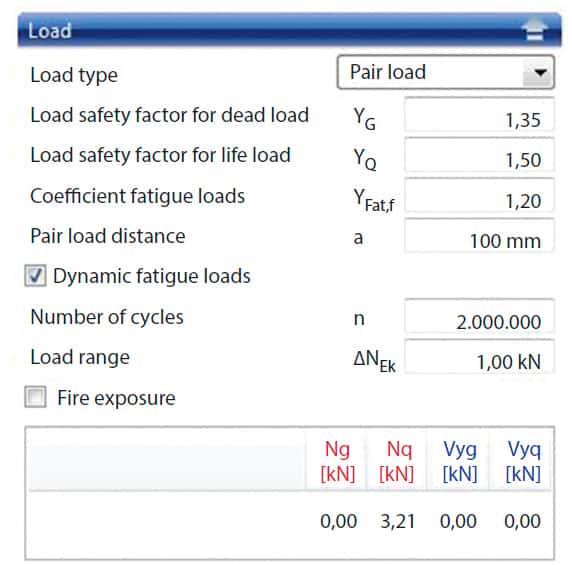

Typical guide-rail connections to cast-in, hot-rolled anchor channels

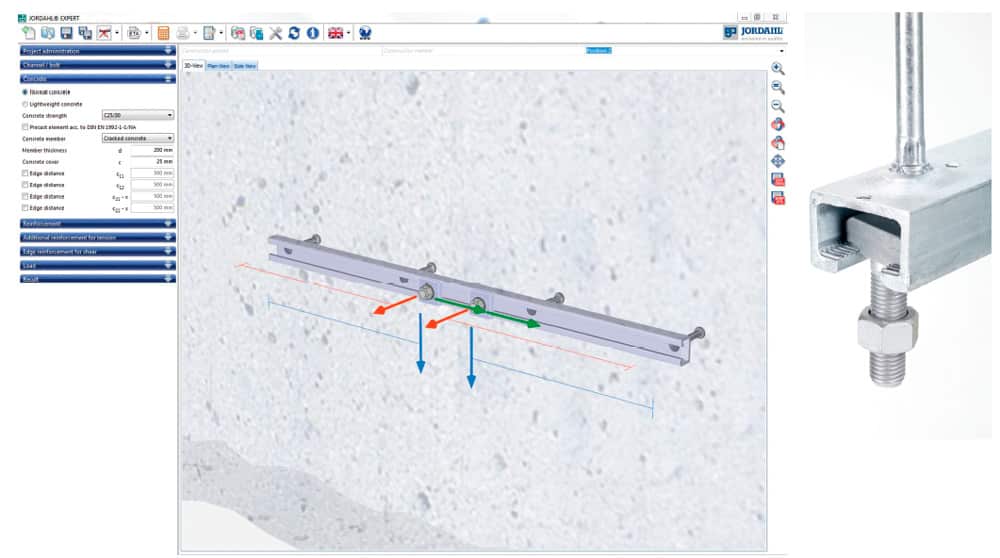

Software is used to calculate suitable hot-rolled, cast-in anchor channels according to required design factors and the range of dynamic loading.

JORDAHL Expert design software: the green arrows indicate longitudinal loading to the cast-in anchor channels as a result of side loading on the elevator guide rail. High longitudinal design loads in the range of 2500-8500 lb. per connection can be supported by the use of JXA W-style serrated anchor channels combined with matching JX-style toothed T-bolts (right).

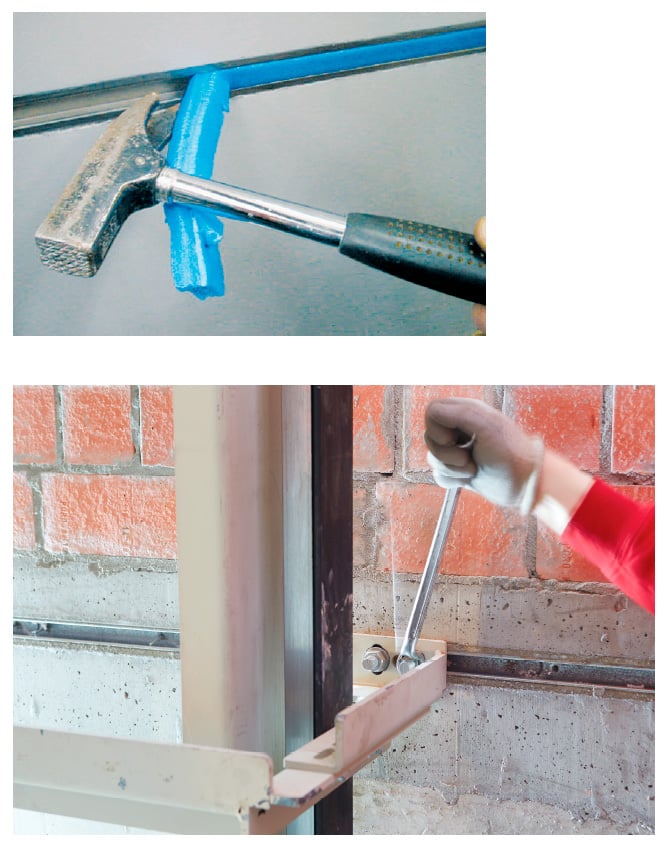

Installing a concrete beam into a new masonry elevator shaft: hot-rolled anchor channel has been cast in to provide adjustable positioning for guide-rail connections.

Elevator-Shaft-Connections-Figure-7

(l-r) Typical T-bolt and hot-rolled channel profile: together, they form a versatile method of providing adjustable and reliable connections to steel.

Hot-rolled JORDAHL channel profiles welded to secondary steel provide secure positional adjustment for door-frame and guide-rail bracket connections.

Hot-rolled JORDAHL channel profiles welded to secondary steel provide secure positional adjustment for door-frame and guide-rail bracket connections.

A concrete worker installs hot-rolled anchor channels to the concrete formwork by nailing them in position.

T-bolts are tightened with a wrench or torque wrench.

Get more of Elevator World. Sign up for our free e-newsletter.