25-year-old Pennsylvania company provides array of entrapment-prevention products.

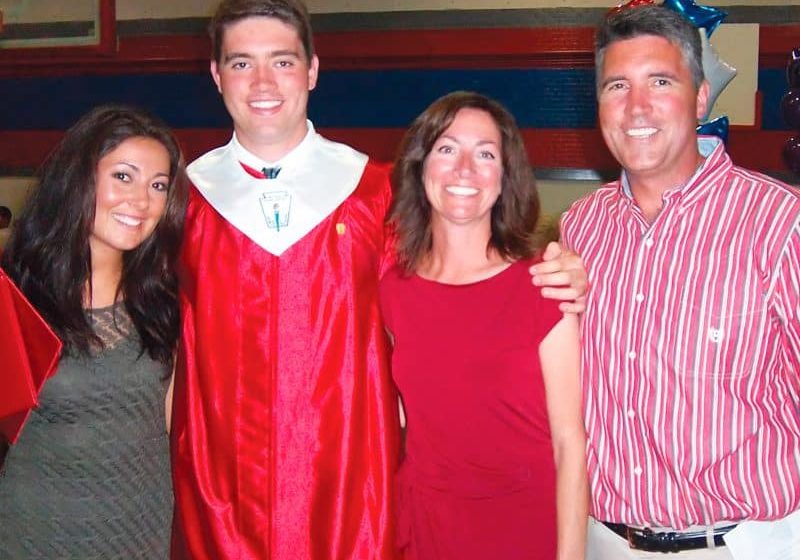

Located in Allentown, Pennsylvania, Reynolds & Reynolds Electronics, Inc. has been in business 25 years. The company was founded in 1989 by the husband and wife team of Bill and Renata Reynolds. Bill Reynolds invented the LXI Battery Back-Up Emergency Power System for Hydros to prevent people from getting trapped in elevators when normal building power was lost. After Bill Reynolds’ death in 1992, Renata Reynolds remained committed to growing the business and cultivating customer relationships. “Bill always stayed very involved with the business, a tradition that continues today,” she observes.

In 2001, Renata Reynolds hired W. John Reinartz, the company’s president and CEO. He states:

“Reynolds & Reynolds continues to invest in the employees, equipment and the facilities. It is very important to reinvest profits, support the core business and recognize employee efforts. Employees share in the success of the business. The company culture is determined by upper management. Every good manufacturing company needs a safe and ergonomically friendly facility; capital equipment that is up to date, reliable and maintained; and skilled, willing craftspeople.”

Reynolds & Reynolds recognizes that the market changes and strives to stay ahead of the technology curve. As the elevator industry grows, Reynolds & Reynolds continues to expand its offerings by developing patented, CSA/UL-approved products for hydraulic and traction elevators. In addition to door-speed controllers, the product line includes application-specific emergency-rescue units, which help ensure power will be applied to an elevator during a power outage, enabling passengers to safely exit the elevator car. Following are some of the company’s top products.

The TPV Series consists of powerful industrial inverters designed specifically for traction-elevator applications. The units contain an integrated contactor for isolating the elevator system from building power during emergency-power mode. The three-phase output of the TPV simulates normal power during a power outage, allowing rescue of passengers who would otherwise be trapped in a traction elevator. This is done by supporting normal function of the controller and door motors, as well as by providing power for the traction brake solenoids and power to the traction motor for movement of the elevator at inspection speed.

Units in the HFP Series are powerful industrial inverters designed specifically for hydraulic freight-elevator applications. The units contain relays for isolating the elevator system from building power during emergency-power mode. The three-phase output of the HFP simulates normal power during a power outage, allowing for rescue of passengers who would otherwise be trapped. This is done by supporting normal function of the controller and door motors.

UV2 Series includes powerful industrial inverters designed specifically for hydraulic passenger elevator applications. The units contain relays for isolating the elevator system from building power during emergency power mode. The series provides single-phase AC and/or DC power to the elevator during a power outage, allowing for the rescue of trapped passengers. This is done by supporting the normal function of the controller and door motors.

RB2 Series units are compact inverters designed to be used with OEM elevator controllers to prevent entrapment in the event of a loss of power.

EBR Option units are compact inverters designed to be used independently (without the controller) to slowly move the elevator in the direction of drift for maintenance and rescue purposes in the event of power loss.

Get more of Elevator World. Sign up for our free e-newsletter.