The future of compliance monitoring of elevating devices by Authorities Having Jurisdiction (AHJs)

by Al Griffin

Introduction

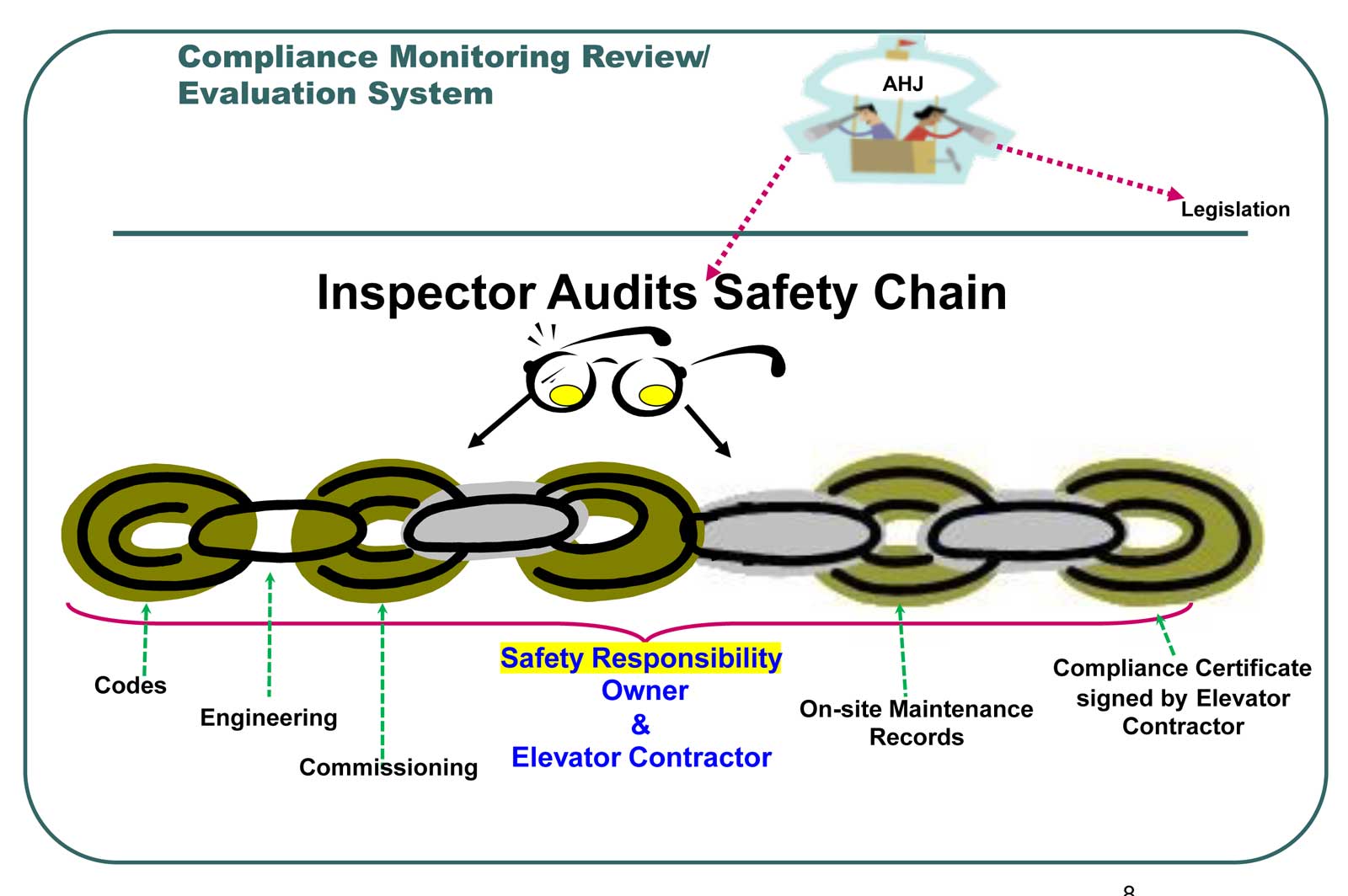

Over the nearly 100 years of providing safety oversight for the elevating devices industry, AHJs have mostly relied on on-site inspection methods to assist both the owner and the elevator contractor in ensuring compliance. This article will show how AHJs could achieve an even higher level of elevating device safety by employing an audit compliance monitoring (ACM) approach that focuses on auditing elevator companies, owners and emergency responders — rather than almost exclusively on hands-on inspection of the elevating device — to achieve regulatory and code compliance.

Principles of Responsibilities

It is important to note that the following philosophy must be taken into consideration when striving to establish a greater level of safety and determine who is responsible. This philosophy includes the following:

- The people who create the risk will mitigate that risk.

- The safety of elevating devices cannot be inspected in; safety must be built into the equipment; service and maintenance are the very fabric of the safety program.

- It is the responsibility of the owner or the elevator contractor to demonstrate compliance to the inspector. The inspector does not have to show or demonstrate safety compliance to the owner or the owner’s elevator contractor.

- Basic auditing of compliance requirements should be based on the following question: Is there evidence from the owner or the owner’s elevator contractor that the safety device complies?

- AHJ inspection or compliance monitoring should not be considered by the owner or elevator contractor as proof of their oversight program.

Background

- The current hands-on inspection system, in most cases, fails to address the root cause of why the same deficiency on the same elevating device occurs year after year.

- Current methodology requires that all inspectors be familiar with and understand all elevator manufacturers’ systems to properly inspect. This change has occurred since the microprocessor-controlled elevator with proprietary systems, sub-systems, components and functions were added over time. Older relay logic systems also did not have E/EE/PES, SIL ratings or duplicate brakes.

- Your author envisions that correct inspection oversight entails verifying the completion of Maintenance Control Plan (MCP) tasks and that mandatory records are available on-site as evidence of compliance, leaving the maintenance or installation companies to provide evidence that they performed the tasks. For example, all MCPs have a task to verify the final limit and door-reopening device. Today, when elevator personnel perform tasks, they have also inspected the operation and repaired or adjusted the equipment to achieve correct performance.

- We should get back to inspecting the essential critical things and not spend hours verifying what a mechanic has already claimed to have checked and tested in maintenance.

- Acceptance is a different matter; everything must be checked the first time around through a commissioning document. Maintenance then brings the elevator to a compliant state, and maintenance is regularly and properly performed to ensure compliance is maintained.

Future Possibilities

Change is not easy, even when it is beneficial. Following are ideas AHJs may employ in the future:

1) Elevator Contractor License

A comprehensive Quality Management Program (QMP) must be based on best practices including, but not limited to, mechanic training, root cause analysis of any deficiencies noted either by the AHJ or during routine maintenance, accident reporting, MCP task timelines and a newly established detailed suspension means log.

The elevator contractor QMP will also set out when an infraction is noted by the elevator mechanic and that it will be corrected within a short and specific timeframe. Otherwise, the device will be removed from service.

The contractor license would be in two parts:

- New Construction and Alteration License

- Maintenance License

Note: Where an elevator contractor fails to reasonably complete maintenance according to regulation and code, the new construction and alteration license may be revoked until such time the elevator contractor proves that maintenance is being completed properly.

2) Auditing

Audits will be used as a benchmark to ensure there is evidence that the entire elevating devices industry is meeting the expectations of the codes and standards and why the system was set up in the first place.

AHJs, elevator contractors, emergency responders and inspection agencies must have their QMP audited. If there is no in-depth auditing of these entities, it indicates the program is basically superfluous and has no value.

The current inspection-only system must shift to a more in-depth audit system to address why deficiencies are being found during the inspection.

3) Acceptance Inspections

A commissioning document stamped by a P. Eng will be provided by the elevator contractor to the AHJ setting out all necessary product testing (including meeting all the code requirements).

Per an “as-built” statement signed by the on-site mechanic, the device complies with the commissioning document and will be part of the process.

The inspector will audit the process to verify that the process is being followed.

4) Yearly Compliance Documentation Attestation

There should be a co-signed attestation by the elevator contractor manager and an elevator mechanic and/or P.Eng. that all aspects of the regulation and code relating directly to the maintenance for which the elevator contractor is responsible are being followed, noting in writing any deficiencies that are not in compliance and that the device owner has been notified.

Compliance attestation documents will include the status of both Category-5 and Category-1 testing requirements.

5) Suspension Means Log

Suspension means verification by the elevator contractor is an area commonly found to be lacking and frequently noncompliant. Little to no record keeping is common. Therefore, an up-to-date, on-site log indicating the current condition of the suspension means, as set out in the requirements of the suspension means manufacturer and the code, is needed.

Note: It is the elevator contractor who is responsible for verification that suspension means meets regulatory and code requirements.

6) Data Acquisition and Analysis

AHJs and elevator contractors will look at the data to determine why there was a deficiency and thereby find the root cause of why that deficiency occurred in the first place and how to prevent the deficiency in the future.

Data acquisition will require that all cited deficiencies be codified so shortcomings can be reviewed and analyzed by frequency and risk.

7) Online Interface Between AHJ and Owners/Elevator Contractor

In the future, a truly interactive system will become the norm, whereby the AHJ and the elevator contractor and owners will have direct access to be able to update their information online.

From the online system, the AHJ, elevator contractors and owners will be able to access up-to-date information and have the ability to mine that information for statistical data and trends. They will, in effect, have their finger on the pulse of every elevating device in their jurisdiction.

8) Emergency Response

In the future, all emergency responders will be required to show the elevator AHJ that they have been trained to ensure safe rescue of entrapped passengers. Training would include provisions to ensure the emergency responder is not injured during the rescue.

9) Elevator Contractor Meeting

A meeting will be set up with the individual elevator contractor to discuss their performance every year.

Summary

The AHJ is an observer or auditor of the safety system to ensure the owner and the owner’s elevator contractor carry out their responsibilities according to regulatory requirements. The owner and the elevator contractor are, collectively, 100% responsible for the safety of the elevating device. The AHJ is not a direct part of the safety system chain.

Conclusion

It is hoped that this article will stimulate ideas and concepts that might or should occur in the future. If these ideas are fully debated and implemented, they could result in a greater level of safety for the elevating device industry.

Get more of Elevator World. Sign up for our free e-newsletter.