Escalators that are Friendly to Humans and the Environment

Apr 1, 2011

Yoichi Ise, Mitsuru Sakaue and Toshiyuki Fukuda MITO Design & Production Division, Urban Planning and Development Systems, Hitachi, Ltd., Japan

This paper was presented at ELEVCON Lucerne 2010, the International Congress on Vertical Transportation Technologies and first published in IAEE book Elevator Technology 18, edited by A. Lustig. It is a reprint with permission from the International Association of Elevator Engineers IAEE (website: www.elevcon.com). This paper is an exact reprint and has not been edited by ELEVATOR WORLD.

Key Words: Safety, energy savingABSTRACT

Recently, the interest about margin of safety and environmental protection has increased. In pursuit of these, and with elaborately designed usability and highly accurate fault prevention diagnosis in mind, a new escalator has been developed. This report describes this escalator’s efforts toward improved safety and its environmentally friendly, energy-saving operation system.

1. INTRODUCTION

Escalators have continued carrying many people in various areas as a means through urban spaces, such as department stores, shopping centers, hotels, airports, and railway-stations and so on.

Hitachi, Ltd. has already introduced into the market the following conventional escalators: the EX series, with enhanced convenience and safety; the FX series, which saves space by shortening the total escalator width without changing the step width; and the MX series, which pursues universal design. However, there has been a growing demand for an escalator with a higher level of safety and lower negative environmental impact.

To satisfy these demands, under the concept of “aiming for escalators that are friendly to humans and environment”, we have developed the new VX series escalator, designed based on four mainstays: the further pursuit of safety, a focus on energy-saving and environmental protection, elaborately designed usability, and highly accurate fault prevention diagnosis.

This report describes the safety improvement efforts and environmentally friendly, energy-saving operation system of the VX series escalator.

2. BACKGROUND AND OBJECTIVE OF DEVELOPMENT

2.1 Growing Demand for Safety

Following a fatal accident caused by an automatic revolving door in 2004, the demand for safety concerning elevator is also growing in Japan.

Meanwhile, the results1 of a survey concerning escalator accidents resulting in injury or death conducted once every five years by the Japan Elevator Association indicates that accidents involving falling and slipping have rapidly increased by about three times from 112 to 359 in the decade (see Figure 1).

According to the report “preventive measures against accidents relating to escalators”2, the Tokyo Fire Department published in 2005, 95.7% of accidents involve falling or slipping, and that elderly persons aged 65 or over account for 53.1% of the incidence of accidents by age (see Figure 2).

To sum up, from taking a look at the above, it seems that an aging society must urgently take measures to prevent elderly people from falling while using escalators.

Recently, in Japan, the National Institute of Technology and Evaluation investigated the number of accidents involving users being caught between the step and skirt panel. The result indicated that as many as 65 accidents occurred from August 2007 through March 2008 where sandals became caught in the escalator. In response to this survey, the Ministry of Economy, Trade and Industry has contacted sandal manufacturers of the kind that account for a substantial fraction of accidents and requested improvement (April 2008).

2.2 The Growing Need for Energy-saving

The period for reducing under the Kyoto Protocol has begun in 2008, and companies have undertaken various efforts to reduce greenhouse gas emissions. Since escalators are always in operation during business hours, mainly in department stores and shopping centers, the interest about energy-saving is increased.

3. IN PURSUIT OF SAFETY

3.1 Mitigating Stoping Shock at the Time of Emergency Stops

As a concept of regarding how an escalator stops when its safety device is operated, the brake torque must be set so that it can stop within a certain braking distance even if a large number of passengers are using it during descent operation. In the conventional general brake system, the brake torque is always constant, cannot be varied, and is higher than necessary under no-load conditions.

The Enforcement Ordinance of the Building Standard Low and the related notice in Japan stipulate that braking distance must be between 0.1-0.6 m and average deceleration should be 1.25 m/s2 or less under no-load conditions during ascent operation.

In developing the VX series, with the prevention of accidents involving falling during use regarded as a top priority issue, we first conducted verification of the relationship between the deceleration and the shock when an escalator stops. During verification, we used test subjects that included mainly elderly people and performed monitoring tests by having them experience various feelings of deceleration, in order to evaluate whether stoping shock exceeds the tolerance limit, whether no problem occurs even if the subjects do not hold onto the handrail, and other matters.

The result shows that 20% of the test subjects grasped the handrail when an escalator stops, although no test subjects were subjected to stoping shock that exceeds the tolerance limit during deceleration under no-load conditions in the conventional braking system.

In addition, the result was that when the deceleration in a stop was set to 60% of the conventional deceleration, stoping shock causes no problems, even if no test subjects held onto the handrail.

The results of the above monitoring evaluation test indicate that when condition of decelerating is set to 60% of the conventional level, the possibility of stumble or stagger can be reduced. However, if condition of decelerating is set to 60% of the conventional braking system and the escalator is full of passengers during descent operation, the braking distance in a stop tends to become longer.

Accordingly, the VX series has adopted inverter-controlled braking to ensure that deceleration is controlled, in order to keep it constant, regardless of operation direction and the number of passengers present, and has also resolved the issue of braking distance. This inverter-controlled soft stop was introduced to prevent falling and stumbling when the escalator stops due to activation of the safety device, or for other reasons (see Figure 3).

3.2 Improving Safety from Being Caught

As a measure to inhibit the recent problem of accidents involving resin sandals that become caught, escalator users are now alerted to correct use, such as stepping onto the escalator within a yellow line around the steps to prevent the user from approaching the part moving in the opposite way (the skirt panel). In addition, a structure designed to make it difficult to approach this part would be effective at preventing accidents.

Therefore, we estimated that providing a protrusion to help eliminate contact with the skirt panel on its section produces a positive effect, and we actually changed the interior deck protrusion amount to check how pressure to the skirt panel section changes with increases and decreases in the protrusion amount. We then evaluated this pressure. The result showed the possibility that increasing the protrusion amount decreases the pressure to the skirt panel and thus could prevent accidents where users become caught.

As a result of the above, an edge (skirt mole) with a protrusion of 15 mm is incorporated into the top of the skirt panel, combined with a conventional 8 mm stepped tread. Figure 4 shows the structure of the skirt panel section adopted in the VX series escalator.

3.3 Preventing Accidents Involving Leaning over the Handrail

In order to ensure safety, it is required by the Building Standard Low in Japan to install guard plates on the cross section that sits in between the building and the escalator. Therefore, we introduced a sensor developed that detects people leaning over the handrail as just one function to support the need for safety (see Figure 5).

The sensor is settled on the exterior deck of the escalator in such a manner that the planar detection area becomes parallel to the handrail in order to detect object outsides the fringe area of the handrail.

As shown in Figure 6, the planar continuous area is set as the detection area to enable detection of anything leaning out, even before users approach the point where they are likely to be caught. For height detection, about 0.5-1.0 m from the handrail section is also set within the detection warning area, which is suitable for adults as well as children. In addition to such detection, this sensor is also effective in detecting people who find themselves on the exterior deck section. When such an instance is detected, a voice synthesizer unit is used to deliver a verbal warning to the users.

Since detection warning consists of a wide area, the situation may occur where the immediate area changes after the escalator is installed. For example, if some type of pole is set up on the exterior deck section, this object would always sit within the detection area. Considering such a possibility, an algorithm is incorporated to differentiate the pole from other users; thus, giving no unnecessary warning if the moving distance of the detected object for each unit time continues to fall below a certain value.

4. PROMOTION OF ENERGY-SAVING

4.1 Energy-saving Technology

4.1.1 The Automatic Operation System (Optional; for additional charge)

A usual method of saving energy in escalators includes the automatic operation system. With a pole incorporating a sensor that detects a user approaching the entrance of the escalator, this system automatically activates the escalator when the user is detected and stops it after a certain period of non-usage elapses. However, this system requires signs that designate the operation direction since the escalator stops completely when no user exists.

4.1.2 The Slow Stand by Speed Operation System (Optional; for additional charge)

This system operates the escalator at slow speed when no user exists, in order to help save energy. The system operates the escalator at 0.17 m/s when no user exists, accelerates it mildly to the rated speed of 0.5 m/s when the sensor detects a user, and slows down it to 0.17 m/s after a certain period of time passes with no user present.

Since this system makes the operation direction visible; thus making signs detailing operation direction unnecessary, this system has better space-saving characteristics than the automatic operation system.

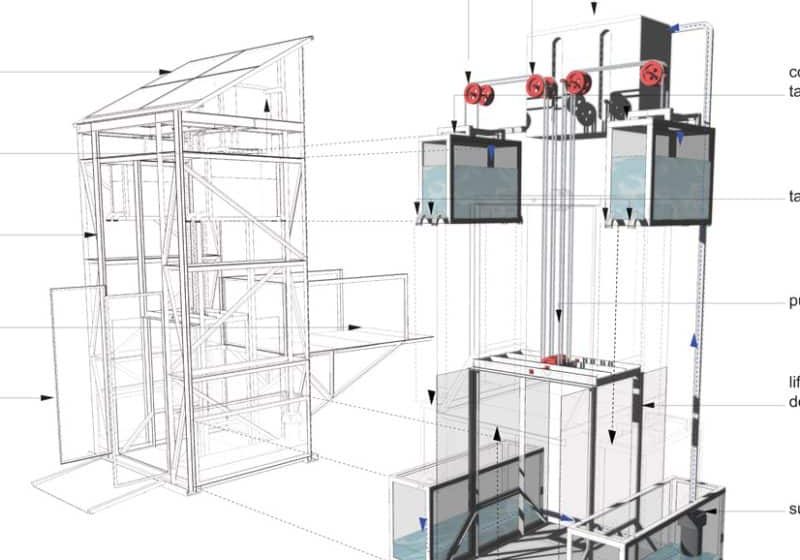

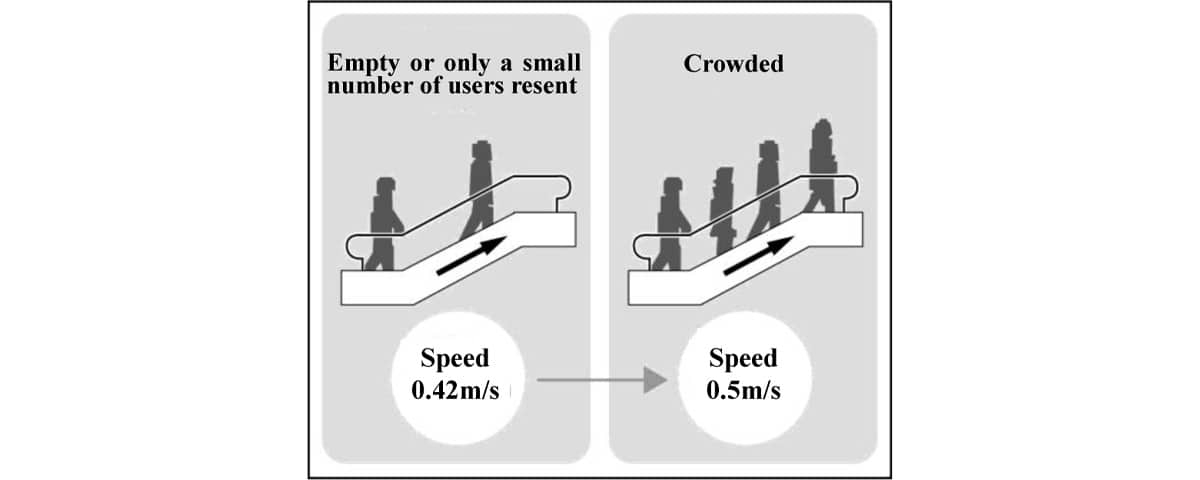

4.1.3 The Eco Mode Operation System: Basic specifications

This system controls speed according to the status of escalator use to ensure energy-saving (see Figure 7). Specifically, the escalator is operated at the rated speed of 0.5 m/s in a crowded state, and a slowdown is controlled in such a manner that is not felt by users

when only a small number of users are present, according to load information from the inverter mounted on the escalator.

As the speed during slowdown is less, the energy-saving effect becomes greater; however, convenience of the user could also be hampered. Therefore, the tolerance of the speed was evaluated by monitoring test subjects, including elderly people, and the speed was set to 0.42 m/s as an optimal speed for energy-saving.

This control system does not require a detection sensor or signs showing operation direction, as required by the previously described The Automatic Operation System and The Slow Stand by Speed Operation System.

This system enables the owner to easily select and set this operation mode by pressing the key switch on the operation panel.

4.2 Energy-saving Effects

Table 1 lists the energy-saving effects calculated for the three types of energy-saving operation systems described above.

These effects were calculated on the assumption that The Automatic Operation System and The Slow Stand by Speed Operation System are activated 15 times/h and that the daily operation time is 16 hours. The energy-saving effects from The Eco Mode Operation System were calculated from an actual measurement taken at a large-scale shopping center.

The Automatic Operation System, The Slow Stand by Speed Operation System, and The Eco Mode Operation System are listed in descending order of their energy-saving effect. However, The Eco Mode Operation System requires no additional facilities and has an energy-saving operation function that is well-suited for any intended purpose of installation. We feel that an escalator with this function introduced into basic specifications can contribute to the promotion of energy-saving more than ever before.

5. GLOBAL DEVELOPMENT

The improvement of making safety and the energy saving are the each country common needs. Though this report is described in the background of circumstances in Japan, Global development is going to be achieved in the future by the arrangement of existing function and the additional new function which is based on the EN standard according to standards and circumstances in each country.

6. CONCLUSION

This report has described, among the items developed for the VX series: the soft stop function that stops escalators slowly in an emergency; security functions, such as

a design that reduces accidents involving being caught between the step and the skirt panel; a function that detects users leaning over the handrail, alerting users to that effect; and energy-saving technology, according to the usage state of the escalator.

In the future, it is considered that escalators will become increasingly widespread, more commonplace, and will require a higher level of safety, especially in regard to an aging society. From the viewpoint of the global environment, the promotion of energy-saving in escalators that have an uninterrupted rate of speed is expected.

REFERENCES

1 Japan Elevator Association. (2006). Elevator World, No.163.

2 Tokyo Fire Department. (2005). Report on preventive measures against accidents relating to escalators.

Get more of Elevator World. Sign up for our free e-newsletter.