The history of Peelle and the vertical biparting freight-elevator door are inextricably linked.

Although it was incorporated in New York City (NYC) in 1905, The Peelle Co. traces its roots to Richmond, Indiana, where Caleb Peelle found himself attracted to the elevator industry due to the amount of industrialization taking place on the East Coast. In 1891, Peelle relocated his family to NYC and began representing the Richmond Safety Gate Co., selling wire-mesh and slide-up-panel hatch gates for elevator-hoistway openings. At the time, hatch gates had few safety features and virtually no fire rating. In those early days, hoistway protection was typically considered separate from the elevator. Hatch gates were sold directly to building owners, independent of elevator systems.

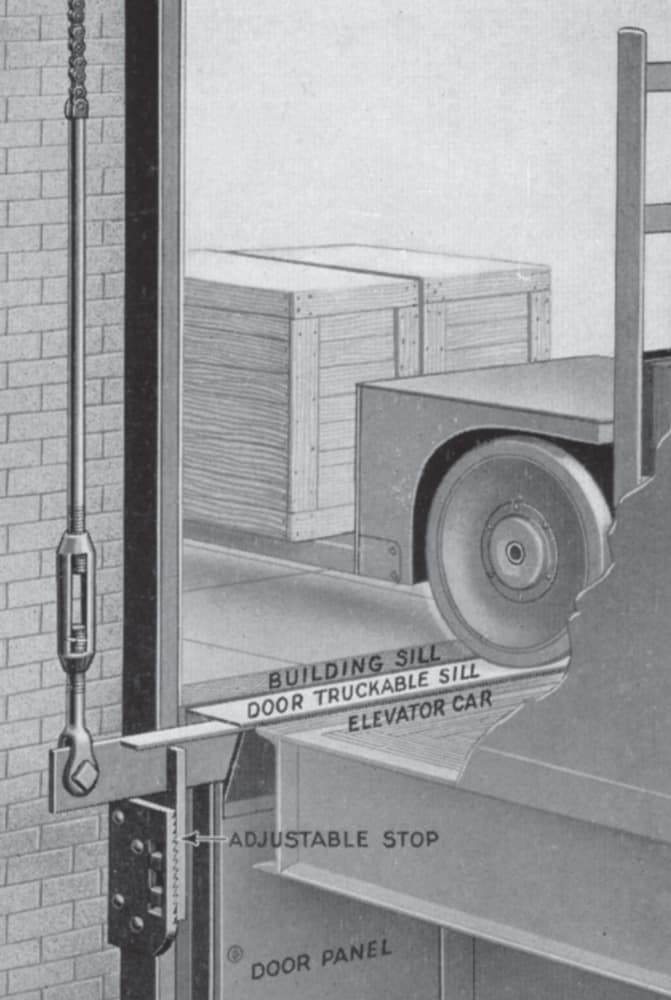

With little more than a decade of experience and an entrepreneurial spirit, Caleb Peelle embraced the challenge of improving the numerous freight-elevator opening-protection designs. He improved the hatch gate and developed a vertically sliding, counterbalanced, biparting door addressing deficiencies he noticed in the NYC freight-elevator market. He was awarded his first patent on April 5, 1904. His design incorporated safety features, fire rating and the ability to move freight over an open door panel. It also maximized platform size by fitting the largest door within the available hoistway width.

After incorporating in NYC the next year, Peelle moved his business into a manufacturing facility in Brooklyn, New York, where R10, the first rugged, manually operated, fire-resistant biparting door with a truckable sill, was manufactured. Its successor, F10S, is still manufactured today by Peelle in Canada. R10 had a wooden core and two pieces of white pine covered with 24-gauge galvanized steel sheets on the hoistway and room side of each panel. While the R10 door was able to withstand both a high Underwriters Laboratories (UL) temperature and the abuse and misuse that can occur during loading, its heavy, oversized panels were sometimes difficult to handle.

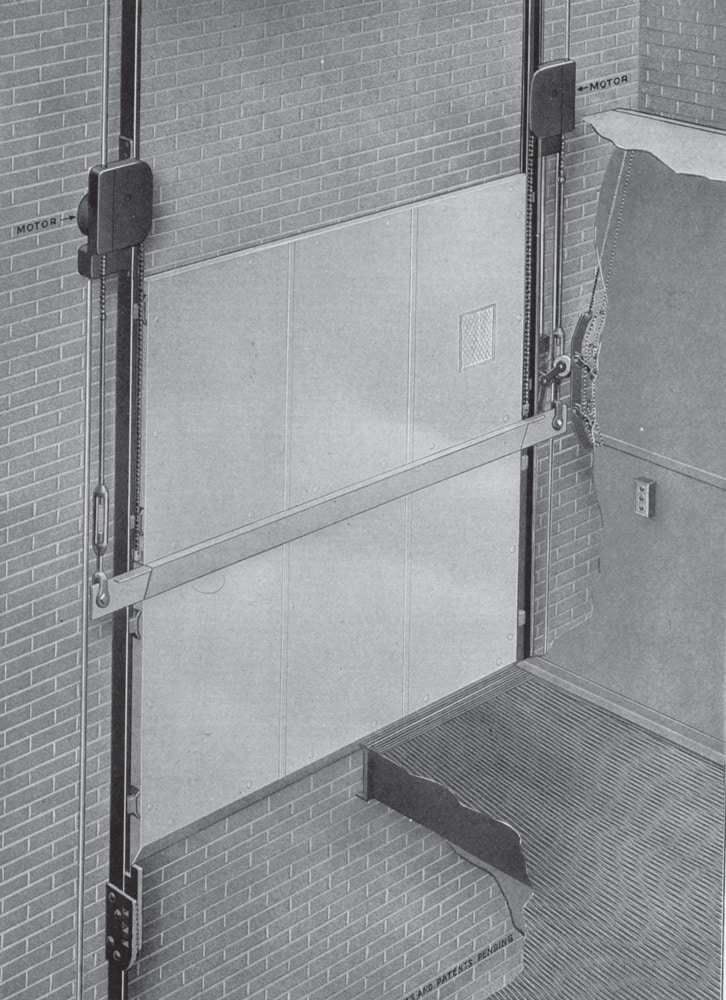

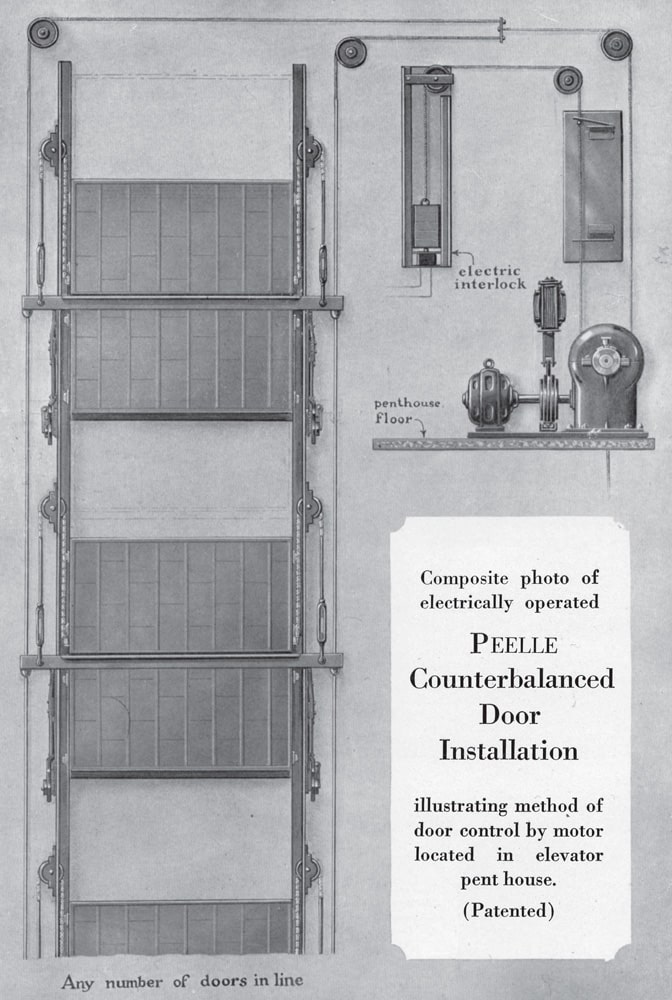

By 1920, the “penthouse operator,” the first practical power-door operator for its time, was Only the doors opposite the stationary elevator were permitted to open.

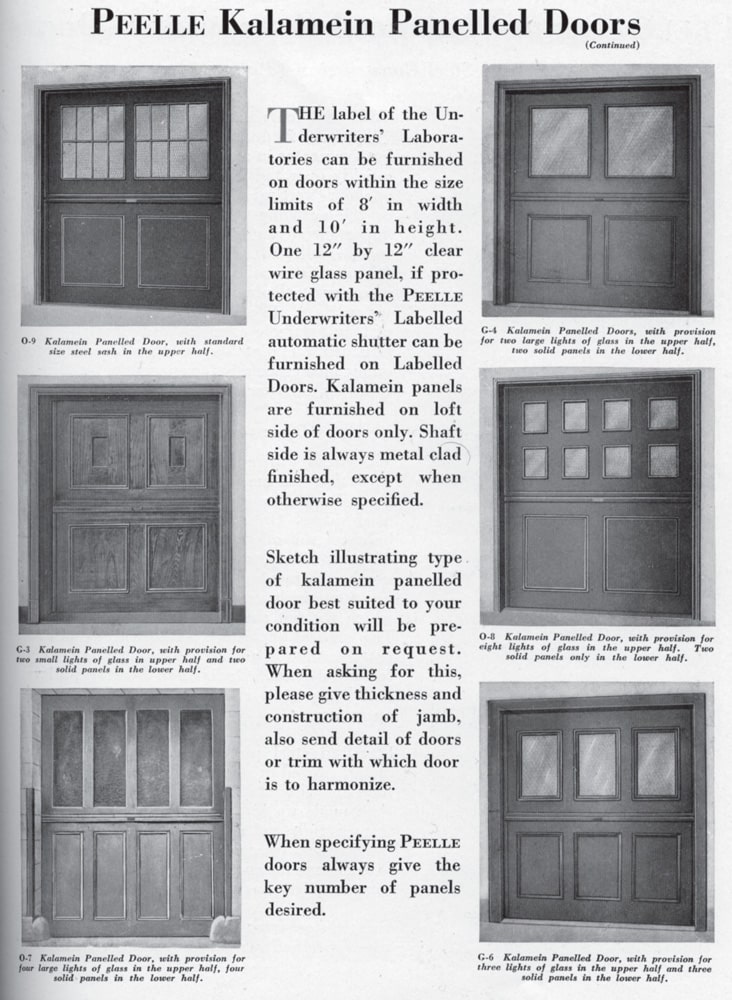

Many door styles were introduced as the freight elevator gained popularity. Peelle provided a self-sealing door to shield the opening from smoke. In 1931, it was the first counterbalanced door to be awarded the UL label and certificate. Today, hoistway protection is far more complex than it was in the early days, thanks to modern codes and workplace rules.

Many door styles were introduced as the freight elevator gained popularity.

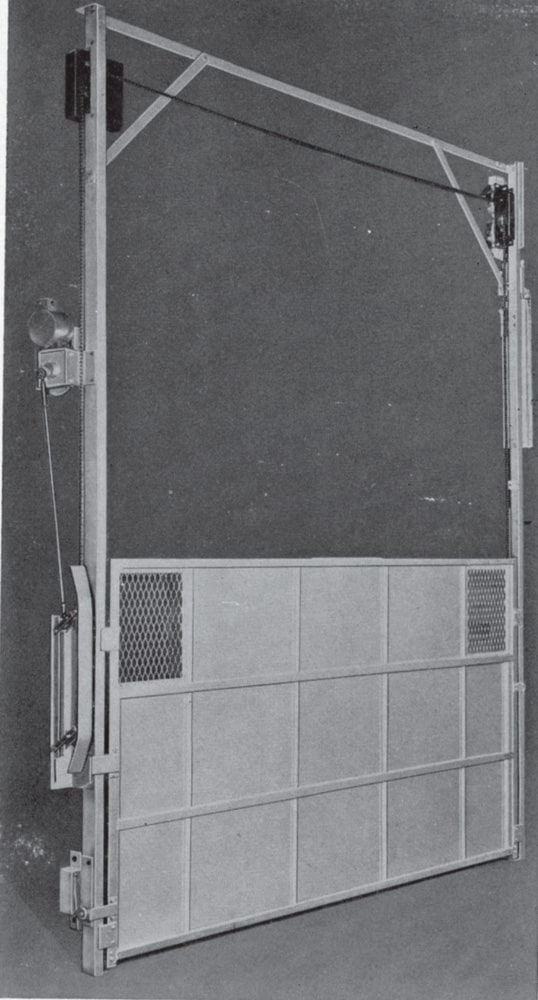

To accommodate customers’ design needs and building requirements, Peelle introduced a number of different panel styles, including a corrugated-steel and counterbalanced medium-height door considered light duty. Later, in order to enhance elevator-door manufacturing efficiency, Peelle would narrow its focus to one style and construction, regardless of unique owner or tenant requests. Eventually, these standards would be adapted by the community and specification writers.

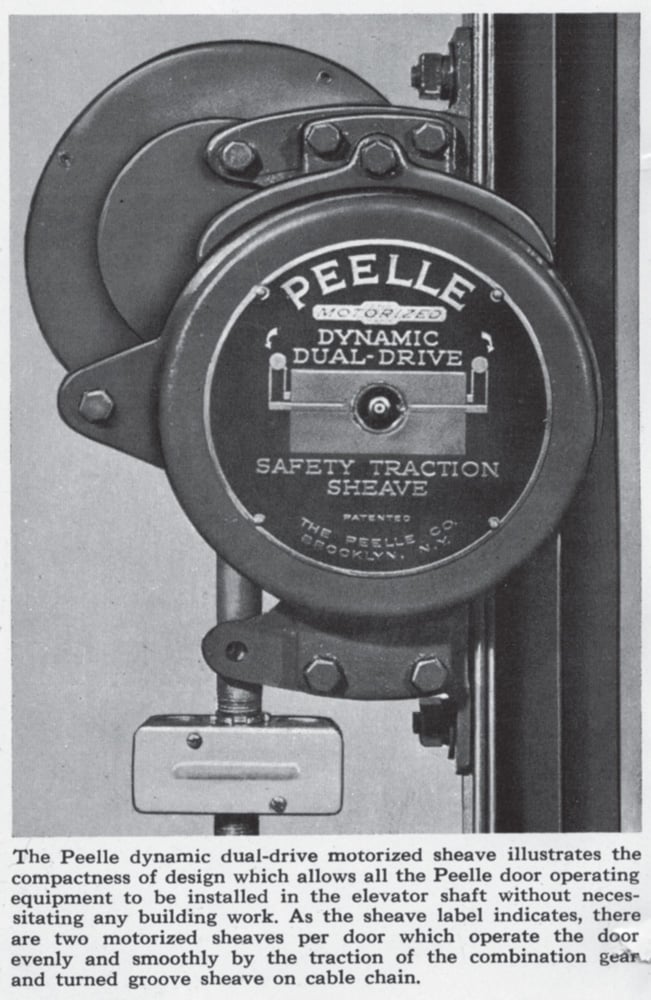

In 1930, single-speed door operators were introduced. Two operators were provided per door, with a relay logic controller. In initial marketing materials, Peelle pointed out that power doors were profitable only under certain circumstances. For example, advertisements from that period would read:

“If the elevator speed is at least 150 fpm, high elevator speed is lost if Peelle doors aren’t motorized. [With] all self-leveling elevators, and freight elevators having continuous traffic, the doors open immediately upon arrival at [the] destination and all freight elevators that completely fill the platform.”

By 1953, Peelle had become the dominant supplier of vertically sliding freight-elevator doors and introduced the two-speed operator. Two operators were still provided on each door, but they were now two-speed: fast for the initial closing/opening phase and slow for the final closing/opening phase. Market feedback found that end users wanted a quieter operation. Slow speed in the final closing phase also produced less impact on material, thereby improving product lifespan and parts-replacement frequency. These speeds were also adjustable, offering the contractor and owner greater flexibility in elevator operation. Around this time, other safety innovations were introduced – specifically, a rubber meeting member between the door panels and “a safety astragal” with side-tension latching, which replaced a steel meeting angel and center hatch.

In initial marketing materials, Peelle pointed out that power doors were profitable only under certain circumstances.

By the middle of the last century, the Industrial Revolution was slowing, and customers demanded more economical and efficient solutions. One of these was the F10S model, a single-sheet, heavy-duty, less-costly door than Peelle’s mainstay product, the R10. F10S was a 12-guage steel-plate door, which was more economical to build than the R10. It offered only a slightly lower temperature rating, was easier to handle, and, although it wasn’t as heavy as the R10, it could handle loading applications and abuse/misuse. The steel-plate door was introduced in 1955 and remains the industry standard today.

In 1960, Peelle opened a Canadian manufacturing facility to handle the Canadian market, in turn modifying its processes to accommodate the same product coming from two different locations. (Peelle had incorporated in Canada in 1926.) Peelle products needed to be manufactured in such a way as to result in seamless delivery to the contractor. This was considerably more challenging than it is today, due to plants operating differently and having additional logistical considerations.

Elevator-control technology also changed. The relay logic controller, though tried and true, was replaced in 1985 with a line of programmable logic controllers (PLCs) offering easy-to-replace-and-acquire components, enhanced control features and the ability to modify a door system’s operation without the expense of a controller replacement. This was also about the time when many elevator-controller companies were gaining popularity.

By the middle of the last century, the Industrial Revolution was slowing, and customers demanded more economical and efficient solutions.

Door manufacturers were attempting to satisfy the controller manufacturers, as well as elevator contractors. Both focused on controller technology, which impacted Peelle’s design and drove new door features. Controllers were also designed for compatibility with numerous elevator-control interfaces.

In 1989, Peelle entered the global market. Horizontally sliding doors were standard, but as loading needs increased and openings grew wider and taller, traditional vertical-sliding, biparting doors gained popularity. Peelle was not the first U.S. freight-door supplier to spread its international wings; there were earlier entrants, but those companies have since left the industry. Peelle needed to adapt to international codes, as well as those of ASME, which required the redesign of key components so Peelle could standardize its manufacturing and parts inventory. Nearly a decade later, this would contribute to its Lean manufacturing efforts. The global marketplace prompted development of multipanel hoistway and car doors, as well as the first-ever slide-down Peelle car gate.

Just five years shy of its 100th birthday, Peelle manufactured its widest vertical sliding biparting door for GMC in Oshawa, Canada. The door was 25 ft. wide and 12 ft. high. To accomplish movement, Peelle provided heavy-duty, high-torque operators, based on the same mechanical principles as traditional doors that operate by counterbalancing each panel. The initial nudge to move the doors open or closed required a more powerful door motor, however.

During the same period when hoistway-door design was evolving, the same was happening with the car-gate door. One of the most obvious changes was the material, originally an expanded mesh. The process to manufacture expanded mesh is to punch holes in sheetmetal, then “expand” the sheet. Although economical, the process produced sharp edges. With safety in mind, Peelle changed the material to a round wire mesh to reject a ball 1 in. in diameter. Peelle took the design one step further and now manufactures car gates in a tight rectangular mesh. It provides a gate resistant to abuse/misuse that also rejects an obstruction as small as a finger.

Car gates also included various reversal devices, which evolved over time. Initially, the mechanical edge needed to make contact with an object before reversing. This contact triggered an electrical strip in the reversing edge, which prompted reversal of the car gate. This edge was later replaced with a sensor beam, which did not require contact with the car door to trigger reversal but did require the object to be within 1 in. of the beam. Peelle provided two drop-down sensor-beam tubes on either side of the car gate, one sender and one receiver. Once the infrared sensor beam was broken by an object, the car gate would reverse. This technology preceded light curtains. To keep pace with the passenger-elevator community, in 2002, Peelle began to furnish light curtains as standard car-gate equipment.

Just five years shy of its 100th birthday, Peelle manufactured its widest vertical sliding biparting door for GMC in Oshawa, Canada.

The freight-elevator door, traditionally vertically sliding, would reinvent itself again in 2008 with the introduction of the Horizontal Sliding Door (HSD) for freight/passenger applications. The Peelle HSD was originally conceived and designed for the European market. It provided a horizontally sliding door for passenger, service and freight elevators. The HSD design offered a heavy-duty door able to withstand abuse/misuse. While suited for passenger applications, it gained popularity in other applications, as well, such as prisons, stadiums, parking garages, museums and anywhere a traditional passenger or standard-size door is not suitable. Unlike traditional horizontal doors, the linkage system was redesigned with no pulleys or cables. Doors were attached and pulled from the center, replicable sill bars, with an integrated header to improve installation.

Wireless freight-door controller technology was introduced in 2010. The design of the freight door hasn’t changed too much since originally introduced. The design consists of steel door panels, counterbalanced and vertically sliding on steel door rails located within the hoistway. Operating mechanisms and controls, however, have changed drastically. These changes often involve improved door performance and installation made possible by technological advances. Peelle’s wireless system was designed with features for the owner and elevator contractor beyond its “technology leap.” For instance, it did not call for costly field labor. Variable-voltage, variable-frequency drives located close to each door/gate, other control systems and older technology required that material be located in the machine room. Wireless technology also required less wiring.

During the past 110 years, the vertical biparting door has undergone many changes, from mechanical design to operating system to installation. Peelle routinely conducts market research with its own installation infrastructure, which provides valuable insight. Over the years, Peelle has improved its product to ultimately provide many years of valuable service for both end user and elevator contractor.

Caleb Peelle’s initial design combined safety and utility.

Caleb Peelle

A variety of door styles became available as the freight door gained popularity.

The single-speed door operator was introduced in 1930.

The 1920s ushered in the era of the “penthouse operator.”

By 1953, Peelle had become the dominant supplier of two-speed operators.

The global marketplace drove Peelle to develop its first slide-down car gate.

Get more of Elevator World. Sign up for our free e-newsletter.