From Local, to National, to International

by Olga Quintanilla

FAIN Ascensores is a Madrid-based company founded in the 1970s that has managed, after three generations, to position itself in the Spanish vertical-transportation (VT) industry and compete internationally. This family of entrepreneurs prides itself on promoting the national fabric and the Spanish elevator components industry, as well as creating jobs directly and indirectly. Its employees and its R&D, driven by its partner Mitsubishi since 2001, are the pillars of this business that continues to advance in projects that reap great success for its members. This is what Gema Mediavilla (GM), director of marketing and communication of FAIN Ascensores, tells your author (OQ).

OQ: Describe the origins of FAIN Ascensores.

GM: FAIN is a company created in Madrid in the early ’70s by Nicolas Mediavilla. In 1999, we began our expansion throughout Spain, starting in Santander, and we now have 31 offices located in four countries. In addition to a wide network of offices in Spain, we are present in France, Belgium and Gibraltar. We are currently the largest family-owned company in Spain in the vertical-transportation (VT) sector. We have 700 employees in Spain, and our annual turnover is around EUR90 million.

OQ: What would you highlight from each family generational stage in FAIN Ascensores’ trajectory?

GM: First, my grandfather: He went from being an elevator technician in a large company to creating his own company, without high qualification as an entrepreneur. Then, my father started from scratch again after the split of the family business. When my grandfather retired, my father refocused the company, leaving behind manufacturing (which was valuable during the ’70s because it was something tangible) to create a company focused on maintenance (which at the time had no value because it was something intangible).

At this stage, we are professionalizing the company, digitizing and improving without affecting our culture, values or the spirit of a fighting family business.

At FAIN Ascensores, we have struggled to create our own space in a sector where we compete with very strong and consolidated companies, where we have gone from being a local company to national, and now, international, and developing our own products, such as the ION Green Solar. We also have to highlight the enormous effort we are making to be present in the new construction market and to introduce ourselves in major projects. We are very proud to have been able to train our teams so they could face these major challenges.

OQ: What kind of difficulties has FAIN Ascensores gone through in its more than 60 years of history? And how did you overcome them?

GM: Growth is difficult, because you discover new challenges and have to readapt the company as it grows. You need to build teams, innovate and transform to move from working locally, to nationally, and then, internationally. These teams need skills and competencies that are very different from what they used to have. Another added difficulty is technology, which has had to be incorporated, in an appropriate way, in line with the company’s growth, not to mention the crises that have forced a different market approach.

Another challenge for FAIN is product technology; we have to compete with other, larger companies with more resources to devote to developing cutting-edge products, such as the ION Green Solar, capable of competing with any elevator on the market. On the other hand, it must not be forgotten that generation transfers are complicated. This involves training staff progressively to take over as other colleagues retire, thus ensuring generational handover in all positions. We have also experienced all kinds of difficulties in FAIN’s international growth.

OQ: What advantages does a family company like FAIN Ascensores offer to the Spanish VT industry in current times?

GM: Large companies manufacture their own products while, at FAIN Ascensores, we use the entire national fabric for the manufacture of our products. That is, we do business with small national industries since our components are, for the most part, local. Our R&D relies only on national companies — not only in terms of product but also in terms of technology.

Multinationals usually produce outside Spain to save costs, and their R&D centers, general services and headquarters are located in their countries of origin. All strategic services are located outside Spain. Therefore, FAIN helps promote Spanish manufacturers and the elevator components industry, as well as create jobs directly and indirectly. Moreover, our taxes stay in Spain.

OQ: Could you explain how you manage a portfolio of 40,000 elevators in Spain?

GM: At FAIN, we rely mainly on two pillars: people and technology. We like to say we have technicians 2.0 because we have trained our technicians and facilitated their work by incorporating the latest technology in their preventive and corrective maintenance work. All of them are equipped with a smartphone and a mobile application. The benefits of this technology redound to our customers and our technicians. Our customers have access to real-time digital service and work reports (including invoicing), and our technicians can consult all their jobs in an orderly fashion with data on customers, types of contracts, previous actions, pending warnings, etc. In addition, they can use GPS to optimize routes, locate other colleagues who are nearby when they need help and even have the ability to reassign jobs to other technicians who are free or closer to the location of a particular notification. In short, this tool reduces the stress level of our technicians, avoids work accidents and, undoubtedly, improves their productivity.

Another important aspect that complements our management of such a large portfolio of elevators is our Customer Service Center. FAIN has fixed staff working at the center. When contacting the center, our customers can choose the language in which they wish to be attended: Spanish, Catalan, French or English. Whether you use phone, email, Twitter or WhatsApp to contact us, there is an operator who attends you with a clear vocation of service.

In our eagerness to improve and carry out a digital transformation of all departments, we have adapted FAIN’s Customer Service Center. The installation of a video wall allows us to geolocate both the equipment under maintenance and the technicians in service. In this way, our operators can allocate resources, plan technicians’ workloads, prioritize notifications and know in real time the status of each one. All of this results in a considerable improvement in technicians’ attendance times, allowing us to meet our commitments and make change in work culture a reality. The employees in this department know what they are talking about, as they receive continuous and specific training to familiarize themselves with our products and services.

OQ: What factors encouraged FAIN Ascensores to expand internationally from a portfolio of 40,000 elevators in Spain?

GM: To diversify risk and make the company more solid. It is enough to remember the crisis that Spain suffered between 2008 and 2012.

OQ: What difficulties did you encounter as a family business in expanding into the international market?

GM: They include inexperience and the significant investment it represents, the need to form a different team than the one you have in Spain, learning to manage a company with very different needs, languages and technology so we can all work efficiently and homogeneously regardless of our workplace.

OQ: What has it meant for FAIN to reach a strategic alliance with Mitsubishi?

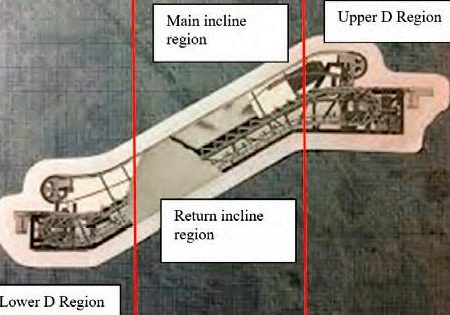

GM: First of all, it has meant recognition of our professionalism and the team behind FAIN. Mitsubishi made a commitment to FAIN in 2001 after a couple of years of analyzing the market and Spanish companies. Every year, we are audited to ensure we can continue to be their representative while training the technical teams in Japan and in their subsidiaries in Latin America. Being representatives of Mitsubishi has allowed us to access a type of customer we previously could not reach because we could not offer certain products such, as escalators or high-speed elevators.

OQ: What new FAIN Ascensores product is generating excitement right now?

GM: We recently launched a line of elevators that are revolutionary in the sector, both for their design and their ability to operate with solar panels and regenerate energy: ION, ION Green and ION Solar. Without a doubt, I would prefer the ION SOLAR Elevator, an elevator that works 100% with solar energy.

OQ: What is particularly noteworthy about the technological solutions provided by FAIN in relation to ION, ION Green and ION Solar?

GM: The first thing is that it is a product made of lighter high-strength steel, which allows us to work with smaller machines. Since the traction system works with a polymer cable, the machine operates with super-reduced energy consumption. In addition, the control system is located in the upper floor door, so all the elements are very reduced, allowing us to maximize the dimensions of the cabin while accommodating more people than competitive models. The GREEN version has a regeneration system and capacitors that allow 100 trips without electricity.

OQ: FAIN Ascensores has developed projects in the residential, commercial, work and leisure areas. In which of them have you felt more comfortable and creative?

GM: The projects we like most are those developed hand in hand with the client, taking into account their tastes and preferences. It is in these more special projects where we stand out because we know how to accompany the customer to provide a technical response to all their ideas. The end result is usually a unique elevator with which the client feels completely satisfied.

OQ: Which FAIN Ascensores project/s would you highlight for their technical complexity or other aspects?

GM: I would cite as an example the elevators of the Reina Sofia Museum, either those of the main building or those developed by Jean Nouvel, who personally designed all the elements of the cabin. Another complicated project was the Hilton Hotel in Madrid because everything is handmade and designed by its architect. In terms of the size of the project, I would highlight the La Fe Hospital in Valencia, with more than 85 lifts installed, and the Málaga Airport, with another 100 lifts.

OQ: Is there a clear demand among your customers for the machine-room-less (MRL) gearless electric elevator compared to traditional products?

GM: Customer demand matches our aim to provide as many ecological products as possible. We offer mainly ecological elevators and, in a very marginal way, hydraulic elevators. Even when the customer has signed up for elevators with a conventional machine, FAIN engineering replaces it with a gearless machine. The FAIN ION machine is not only a gearless machine, it also has a built-in traction system with a polymer covered cable that makes consumption even lower than with a conventional gearless machine.

OQ: Do you think that the hydraulic elevator will continue to evolve, or will it tend to disappear in the face of technological progress?

GM: In countries like France, where sensitivity to the environment is more developed than here, it is a product that can be said to have disappeared. In Spain, it is only used for very specific projects (car lifts and domestic lifts, for example), due to the use of oil. Now there are technologies that do not generate waste and consume much less and need less space, as they do not require a machine room. The technology may continue to evolve. Electric technology may be applied to the hydraulic elevator, but I doubt its demand will grow.

OQ: How do you envision VT in the long term?

GM: Predictive maintenance will have more and more weight. This technology will change the sector and greatly improve the quality of service and elevator operating times. The technology will change the product, making it a product with low energy consumption. This already exists, but it will have more presence in the market.

OQ: What are your short- and medium-term objectives in Spain, and what are your plans for international expansion in the medium and long term?

GM: We aim to continue growing in Spain, so we have more resources to provide a better quality of service. On the international side, our intention is to continue growing so our company acquires greater strength. Our next challenge is to export our products abroad.

Business Milestones of Fain Ascensores

1972: FAINASA was founded as a result of the spin-off of Ascensores Mediavilla (AMESA).

1989: Change of the commercial name to the current one: FAIN Ascensores

1990: Opening of our central office on Doctor Esquerdo Street in Madrid, the first commercial office in the sector focused on customer service

1999: Expansion throughout the national territory begins with the branch office in Santander.

2001:

- Purchase of 2,100 elevators from JARRE ELEVADORES, which means presence in Avila and access to special equipment and prestigious buildings.

- Signing of the commercial agreement with Mitsubishi, which regulates the exclusive distribution of the product in Spain and Portugal.

- First control panels with FAIN Ascensores technology.

2002:

- Expansion continues at national level (Murcia and Almeria).

- The first elevator is installed in a large shopping center (Opción in Madrid).

2003:

- Opening of the Cataluña and Valencia branches. In the latter, FAIN provides all the elevators in the largest hospital center in Europe, La Fe.

- FCC awards us the installation of our first medium- speed Mitsubishi elevator installation in the Garena Tower in Alcalá de Henares (Madrid).

2005: Implementation in Málaga

2006: Implementation in Granada and Cádiz

2007:

- FCC awards FAIN the contract for the Fira towers in Barcelona, with high-speed lifts at 4 m/s, the fastest in Catalonia.

- Implementation in Gibraltar

- Record of 1,850 new construction elevators reached

2009:

- Implementation in Seville and Huelva

- Implementation and start-up of the SAP management system

2010:

- Implementation in Alicante

- Implementation in Salamanca

- 30,000 satisfied customers in our maintenance portfolio

2011: Implementation in Bilbao

2012: Implementation in Cordoba

2013: Implementation in France through the purchase of three local companies

2014: Open a new office in Toledo

2016: Establishment in the Canary Islands and Extremadura

2018: Implementation in Belgium through the purchase of a local company

2019:

- Launch of ION

- Diversification towards charging points for electric cars, solar panels and electricity supply

- Implementation in Navarre

Get more of Elevator World. Sign up for our free e-newsletter.