Fire-Resistant Elevator Doors in Europe

EN 81-58, the official European standard since 2004, has a long history. It defines the procedures for door certification, as well as their fire-resistance classification. Each country’s fire department establishes to which class of fire resistance the doors to be installed in buildings should conform. Before the European Union, each country had its own standards, and elevator-door manufacturers were obliged to obtain certifications in various countries that adopted different test methods. Therefore, the costs for certifying fire doors reached huge amounts.

There were also countries that did not require the passing of any test for fire-door certification. Germany was one such country, employing DIN 18091, which required specific construction schemes and minimum thickness of plates for the manufacture of door panels and frames. It was later experienced that the doors constructed in accordance with DIN 18091 were not able to prevent the passage of fire from one side of the door to the other. New rules were issued (DIN 4102), according to which, the elevators required to have certain characteristics of fire resistance had to be of the F90 class. This rule stated that a fire on one floor of the building could spread to the upper floor only after passing two doors: one on the floor where there was the fire, and the other on the floor immediately above.

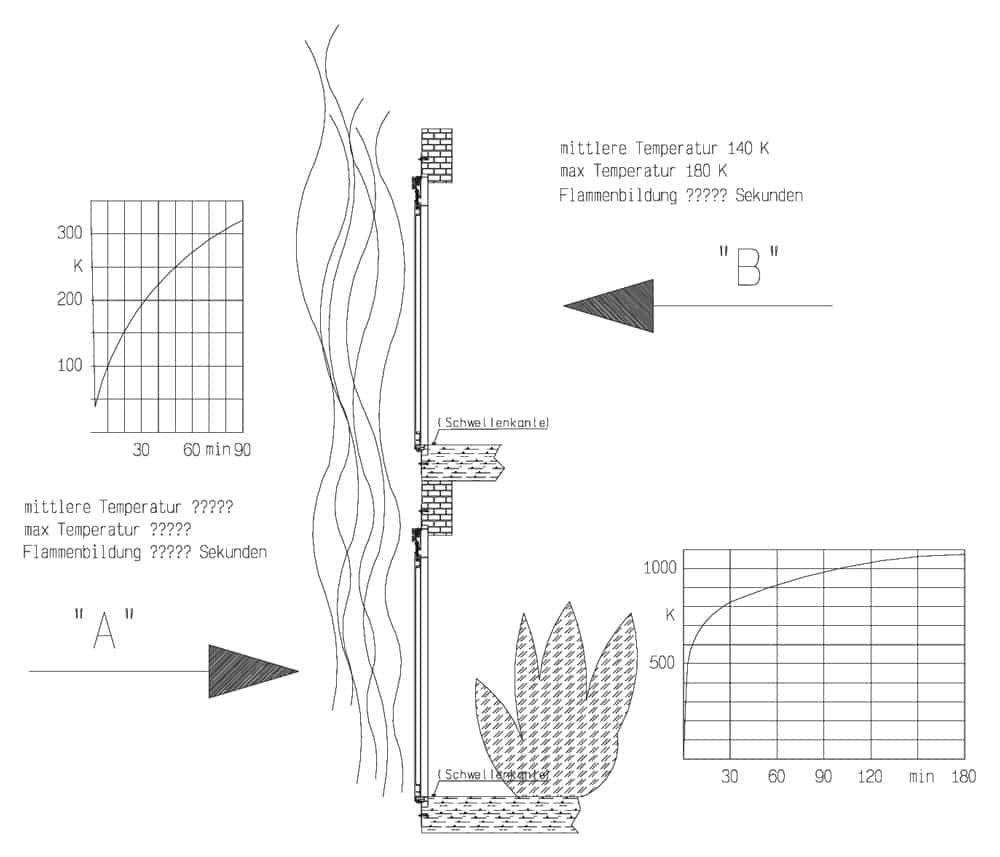

The rule specified two tests be carried out: the first with the landing-door side toward an oven that reached 822 K in the first 30 min., and the second with a new door installed with its shaft side toward the oven emanating superheated air (according to the curve found in DIN 4102, Part 5, page 7 that states it reach approximately 191 K after 30 min.). Such a double test simulated the real situation of a fire in a building (Figure 1).

After many years of the tests being carried out in a furnace, it was found that changing the dimensions of the door but maintaining the same number of panels results in change. Since there was not an approved furnace suitable to test doors with the biggest dimensions, a Notified Body (NB) was required to grant authorization for testing large doors in a much bigger oven. A furnace in Pionki, Poland, was only recently approved with a clear opening of 5-m wide X 4.5-m tall. Prisma S.p.A. in Casale di Mezzani, Italy, was the first manufacturer of elevator doors to carry out a fire test on a large-dimensioned door in this furnace. These tests confirmed that the current method for granting assessments is not correct, since it does not correspond to the reality. With the increase in the size of the door, there are many things that need to be modified in its construction in order to pass a fire test.

Figures 2 and 3 show the construction of a door with a clear opening of 3,300-mm wide X 4,000-mm high. It has the same kind of insulating material and same construction system as a door with clear opening of 2,600-mm wide X 2700-mm high. The deformations of large doors are greater than those of smaller doors. The construction of the big door must be completely changed: thickness, depth of chicanes and even insulating materials must be different from those of doors with smaller dimensions. Figure 4 (taken during the test) shows the test of the large door, which passed.

The structure to which a door is fastened has strong importance (Figure 3). Elevator doors installed in ships that require fire-resistant doors are special cases. In them, doors are fixed to

Figures 5-7 show two successfully tested Prisma doors: one center opening, one speed, and one center opening, two speed, fixed to a steel bulkhead. Our experience has taught us the necessary construction differences between larger and smaller doors and the NBs will now have to reconsider their theories and cancel their assessments issued for doors larger than those actually tested. This is because only a test carried out on the real size of the door can give one the assurance of compliance with resistance ratings. While an effective door smaller than those of the samples tested can be built with the same features, construction techniques and insulating materials, the opposite is not true. Our experience has also shown that a ship’s lift fire door fixed to a steel bulkhead should be constructed differently from the same door fixed to a wall in masonry or reinforced concrete.

Get more of Elevator World. Sign up for our free e-newsletter.