DMG has more than six decades in the industry, but its sights are set firmly on the future.

Rome-based DMG has been providing elevator fixtures, such as push buttons and hall indicators, for more than 60 years. Starting as a small, family business, the company today has a global presence and makes more than buttons and panels — it has become known for controllers, cabins and its in-car communication and information displays. At a 10,000-m2 headquarters facility in Rome’s Pomezia district, about 160 people work fabricating metal and plastic parts, assembling controllers and fixtures, and brainstorming in an R&D operation focused on taking the company into the future.

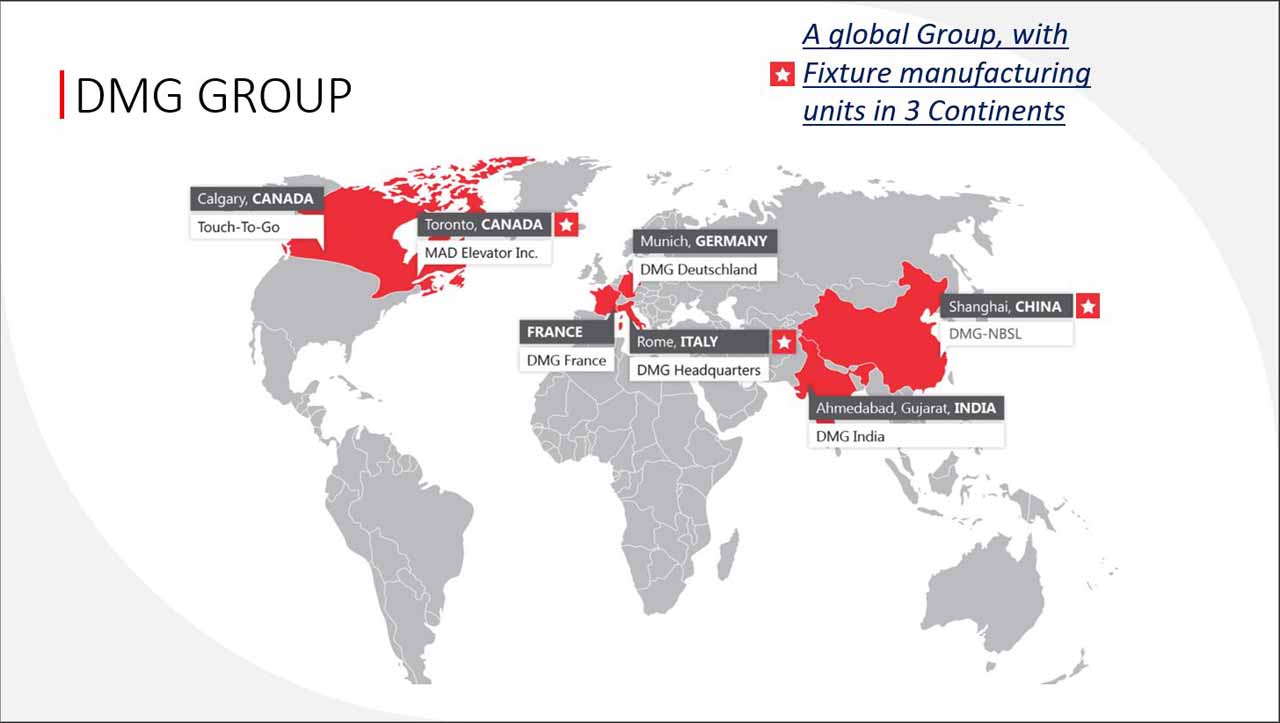

In addition to the Rome headquarters, DMG is majority partner in a joint venture (JV) with cab and fixture maker MAD Elevator Inc. in suburban Toronto and participates in another JV with component maker NBSL, based near Shanghai. With manufacturing facilities in Europe, North America and Asia, DMG is, as CEO Emanuele Emiliani says, “The only global fixture manufacturer in the world.”

Emiliani says DMG was founded in the 1950s by his grandfather, Nestor Emiliani, and great-grandfather, Giuseppe de Matteo (the company name stands for “De Matteo Giuseppe”). Emanuele Emiliani’s father, Ernesto, continues to serve as company president and remains “part of the game; still involved” in operations.

Focus on Fixtures

Emanuele Emiliani said fixtures are DMG’s primary product, and the company develops, designs and manufactures “all the components that fit into fixtures and control panels.” He said the company manufactures push buttons, position indicators, emergency phones, load-weighing devices, key switches, touchscreens and more, continuing:

“In Europe, we have important business in elevator controllers and electric systems for elevators, but as we speak today, this part represents no more than 20% of the global turnover for DMG.”

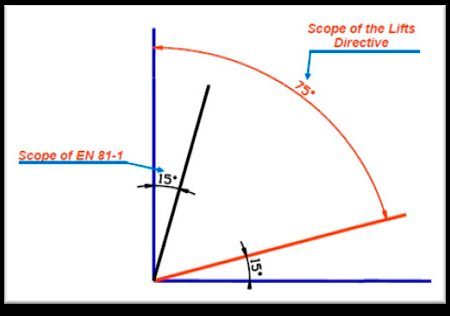

Emiliani said DMG’s fixture line is focused primarily on the modernization segment, though Schindler and Otis are among its new-installation clients. “On the other hand, our controller business is primarily dedicated to modernizations in Europe, so the electrical system is sold to customers in 12 countries, which is part of our uniqueness” in this segment. “In Europe, every [other] controller manufacturer you find in the continent is primarily focused on its own country,” he said, pointing to a number of factors — primarily, local requirements. He explained:

“We have the European norms, but we also have a number of national requirements [that] may vary from country to country. So, the controller we’re selling in Italy is not 100% the same package we sell in Germany or in France. You have to adapt to local requirements.”

The same is not true for fixtures, and this part of DMG’s business is better positioned for the global market. Emiliani continued:

“This is easier, because we can sell our buttons and position indicators everywhere in the world if we want. Fixtures made for North America are different from the ones you find in Europe and, even within Europe, you have differences from country to country — not necessarily linked to national laws, but to taste, style and tradition.”

International Strategy

In the 1990s, Emiliani said, his father began “the international spread,” which today is most visible in the company’s three factories — “The one here in Pomezia, Rome, the one in Toronto, Canada, and the other one southwest of Shanghai.”

“Our focus is international,” he said, noting, “80% of our business goes outside Italy, for many, many years now, and not necessarily [only] Europe. I would say Russia, the Middle East and even countries far, far away are home to our customers.” He said DMG’s international strategy involves setting up “directly owned, directly managed” offices in the various countries where it does business:

“Then, we also started to have . . . franchisees, [such as] DMG Netherlands, where we basically don’t have physical manufacturing. We have countries in which a person is using our name, licensed from us, and selling our products exclusively. We want to be local — the person has to be there, knowing the market and being in play 100% of the time. The other [business] model is to have long-term contracts and relationships with distributors or even big customers. For instance, we have one big distributor in [the] U.K., and he takes care of literally 80% of our market in the country.”

The Rome factory supplies customers across many parts of the world: Europe, the Middle East and several distributors in North America. “Our top 10 key accounts [include] most of the main multinationals — Schindler Europe, thyssenkrupp USA and Europe, and Otis,” Emiliani said, adding that DMG works with several KONE units, such as KONE Italy and KONE France.

He says globalization is probably the biggest challenge DMG has faced in recent years:

“In Europe, especially, the market has changed dramatically over the past 10 years, and this was strongly influenced by globalization and the opening of China’s market. So, we had to face the impact of aggressive competition from low-cost countries, especially as far as components are concerned. Chinese companies are selling in Italy and Europe, just like they are in the rest of the world, and that’s something the local companies are up against.”

Emiliani said even entering the broader European market was met with resistance, due to the norms, adding:

“Same story in North America, with the American Society of Mechanical Engineers code, which does not necessarily match [the European] one. I think that this was a positive challenge in that the fittest companies are able to align themselves to global competition, to aggressively search for reduced costs, improved production processes and a very defined R&D process that is in a constant search for simpler components and more-effective production processes.”

In late 2018, DMG entered into a JV with NBSL, a Shanghai-based maker of door operators, machines and other elevator components. The JV became operational in the second quarter of 2019, occupying a 5,000-m2 plant manufacturing fixures. Emiliani explained:

“When we went to China to negotiate agreements with local companies, we said, ‘Hey, we know how to do fixtures; you know the local market — let’s get together and do something nice in China. This is our next challenge: to become a truly global company able to sell in every part of the world with localization and a good product for the right market. Our goal is to be able to sell to Germany and China. Not with exactly the same approach, not with the same prices, not with the same type of components, but our mindset should be that we are able to tackle both challenges.”

Emiliani said the NBSL JV is going well because “this company is one of the best examples of a good Chinese company.” He said the fit between the two companies was very good from the start, which led to a quick agreement for the partnership: “[NBSL has] a very good ownership and management. It’s a very well-established company with great attention to quality, the product and R&D, so we found ourselves speaking the same language, even if the ‘language’ is completely different.” He said the negotiating process was quick, and, once up and running, DMG was manufacturing fixtures alongside NBSL’s component-manufacturing operation in a situation he likened to “an incubator.”

“It’s a nice way to jumpstart a manufacturing process in China,” he said. “We started the company a little more than one year ago, and it’s gearing up to full production. So far, this is a very good example of international cooperation, especially with a Chinese company. Our expectation and desire is to make this a very positive example of a JV, just as MAD has been for 15 years now in Toronto.” He said the Shanghai plant’s products are primarily for the Chinese market, but the long-term goal is to export them to other parts of Asia and the Asia-Pacific region.

In 2017, a new, 80,000-ft2 MAD JV facility in Mississauga, Canada, was opened. There, 180 employees produce 3,000 fixtures and 500 cab interiors per year. The staff includes project managers, engineers, quality control, sales staff and more.

Growth Areas

DMG is looking to expand its position within several product lines. One important growth area for the company is in what Emiliani calls the “visual system business,” based on thin-film-transistor (TFT) and LCD screens in products ranging

“. . . from smaller position indicators to large digital signage systems to very big entertainment screens. Many years ago, we were manufacturing position indicators [as we] pioneered the lift LCD era in Europe. That is, we started many years ago to extensively offer TFT screens as position indicators in all our fixtures and did the same in North America with MAD. Today, we have the largest range of LCD indicators in the business — from 2 to 22 in. as standard position indicator, and larger screens for digital signage applications, entertaining and so on.”

These panels can be used both inside and outside the elevator. The largest screens, called Matisse, offer vast possibilities for content (such as advertising, weather and local information), which can be delivered either through the building’s local area network or the DMB 4G router. The Matisse package includes both the hardware and MosaicONE, a content-administration system that is among DMG’s in-house software offerings — a growing part of DMG’s business, Emiliani said. He continued:

“Why software? Because these types of screens are designed and built to be connected. Connected screens means having something that is natively connected to a cloud system, cloud software, which we have developed for this one. It allows everyone — every owner, every building manager or customer, whoever it is — to connect in a very simple way to an existing screen in the elevator and modify and create new things, change content and update information in a very simple way. And this has proven to be a concept that is paving the way for our growth in this business. So, in North America where this larger screen is really appreciated, this mix of a beautiful screen and very effective, nice software is going into mass production.”

DMG’s homegrown software allows users to connect to the screens from virtually anywhere. “So, our software is very powerful and has been developed and maintained in-house. We’re transforming ourselves into a software house, to a large extent. We have five engineers here working exclusively on software.”

The company’s software isn’t limited to digital screens, however:

“We have created an app for smartphones to control our controllers connected to the internet. So, from here or from anywhere, a customer can check the status of their own lift equipment. They can change parameters, check diagnostics, receive and pass on information in a very simple way. The abilities of DMG’s platforms are dependent on robust and user-friendly software. We decided to hire software engineers, which changed our skill as a component manufacturer and is more crucial for us today than having a mechanical engineer designing the shape of a new button.”

The Matisse panels are interactive, meaning passengers can use the touch capabilities to choose the information they want. “Virtually all of the touchscreens made in North America are made by us, under the name Touch To Go,” through the MAD JV, Emiliani said. He added that the screens can be found in elevators installed in a wide range of facilities, from the Museum of Modern Art in NYC to airports, hotels, commercial centers and shopping malls — in more than 2,000 locations “and going up every year.” He continued:

“Our touchscreens are based on large screens equipped with very strong and robust performance, with the touch layer replacing the push buttons for elevators. So, basically, instead of there being all the traditional buttons, you can substitute that with the touchscreens that also allow for large, entertaining graphics in the elevator.”

“That’s the future,” Emiliani said. “The future is, everything will be on the screen.”

Controller

Another target for growth is the European controller market. Emiliani said DMG is aggressively seeking market share for its new controller platform, Pitagora 4.0, “a complete electrical system for elevators.” He continued:

“This is the fourth generation of our core product, and it’s consistent with our target of being the leading controller manufacturer in Europe over the next three to five years. We have a product that is very advanced and for which we are not only manufacturing [the hardware], but also providing the software, because this is one of our competencies. We have engineers developing our own software, and we think this is going to be the foundation of our growth in Europe.”

Pitagora 4.0 is, company says, Europe’s first integrated controller and variable-voltage, variable-frequency (VVVF) inverter. It complies with EN 81-20/-50 and offers cloud-based connectivity and advanced functions. It features a Fuji LM2 VVVF unit; a 32-bit motherboard; CAN bus communications to car and floors; and support for up 28 floors at 4 m/s. Its Live+ security system allows riders to surveil a floor before opening the doors, and it can automatically put elevators into standby mode, shutting off lights, position indicators and other functions to save energy.

It’s available for machine room traction and hydraulic systems, or for machine-room-less traction systems. Using DMG’s Fusion app, owners and service companies can connect to Pitagora 4.0 by smartphone or PC, either through local connection, WiFi or remotely through the cloud. This enables them to receive and process error messages, track controller functioning in real time and perform advanced diagnostics. The system also has plug-and-play capabilities, allowing easy connection of prewired connections to a Global System for Mobile Communications wireless gateway/emergency telephone system or a 4G router that allows connection of both an emergency telephone and a Matisse multimedia display.

DMG has an installed base of more than 12,000 Pitagora controllers in Europe.

Ordering from DMG is facilitated through the company’s proprietary Magellano software. Buyers can view the full product line, complete with technical specifications, drawings and prices. Using computer-aided navigation, customers can go from order setup to final quote. The company is certified ISO 9001:2015, ISO 14001:2015 and BS OHSAS 18001:2007.

DMG can usually be found spreading the word about its products at the major tradeshows, in publications and through its website and social media sites, and through newsletters. A new channel Emiliani is looking at is webinars, which he said will allow DMG to present more in-depth information about the increasingly complex technology involved in all of its products, from push buttons to touchscreens. Emiliani said the webinar presentation is similar to the traditional, in-person technical visit, in that both allow the company to explain how its products work. They differ in that the in-person meetings may involve up to 20 visitors in the room, but the webinar “can be more one-to-one.”

Going Paperless

Emiliani said DMG is converting its technical documentation from paper to an entirely online library:

“We’re creating a customer website, a technical support website, whereby all of our technical documentation will be delivered under the form of ‘wikis’ — wiki pages linked to one another. Basically, [they form] a large knowledge base on our products that will allow people to retrieve technical information about our products and guidelines, and installation guides accessible from their smartphones and PCs, instead of from traditional user manuals. We have been printing a lot of user manuals for the packages. That means tens of thousands of physical pages, and if you think about how much we are wasting in terms of paper, there is a different way to do that in the future, and as an environmentally conscious company, we would like to go that way to digitize everything and avoid, as much as we can, traditional paper.”

Get more of Elevator World. Sign up for our free e-newsletter.